Posted on Sunday, November 23, 2025

Electrical faults are one of the most common causes of downtime in roll forming production. When a machine loses motor power, starts misreading encoder values, or suffers a panel wiring failure, production can stop instantly — costing thousands per hour.

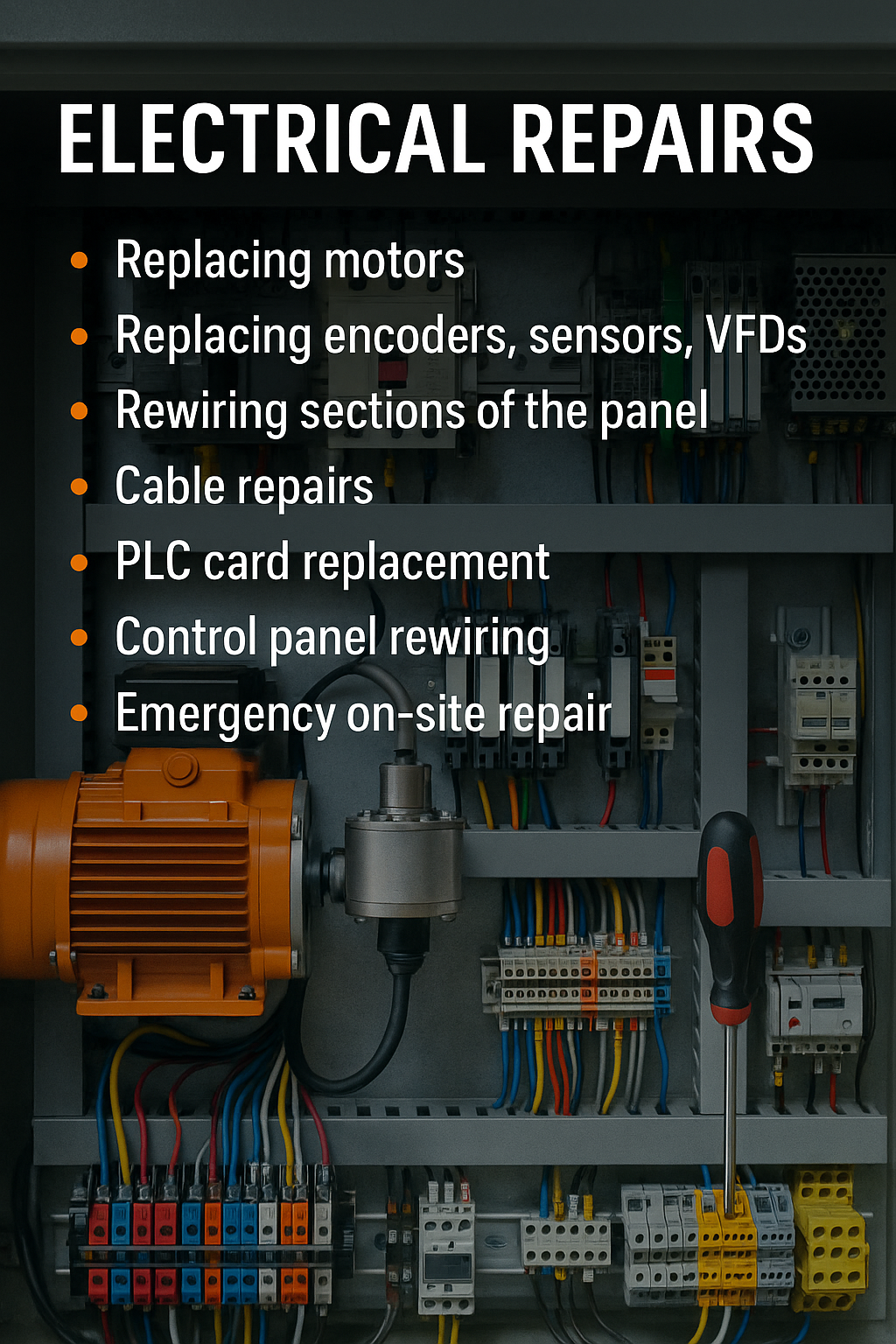

Machine Matcher provides fast, professional, OEM-independent electrical repair services for all brands of roll forming equipment. From minor cable repairs to full panel rewiring, our technicians diagnose problems quickly and restore your line to safe, accurate operation.

Below is a complete overview of the electrical repair services we provide.

A failed motor can shut down an entire line. Common causes include:

Phase imbalance

Overheating

Bearing failure

Undersized cables

Voltage spikes

Incorrect overload settings

Motor testing & diagnosis

Removing old motor safely

Installing new motor

Shaft alignment & coupling checks

Setting overloads & motor breakers

Testing rotation, torque, and current draw

Updating panel labelling & documentation

We handle AC induction motors, servo motors, hydraulic pump motors, brake motors, and VFD-driven units.

Electrical accuracy depends on clean signals from sensors and encoders. When these fail, production becomes inaccurate or stops entirely.

Rotary encoders (incremental & absolute)

Proximity sensors

Photoelectric sensors

Pneumatic sensors

VFD (Variable Frequency Drive) units

Servo drives

Safety sensors and interlocks

Diagnosis of root cause

Wiring verification

Parameter setup for new VFDs

Encoder calibration

Sensor alignment

Testing with live production

Documentation update

We ensure the machine returns to accurate and safe operation.

Old machines frequently suffer from:

Brittle insulation

Burnt wires

Loose terminals

Overloaded breakers

Poor-quality cables

DIY modifications

Removing damaged or unsafe wiring

Installing new industrial-grade cables

Re-terminating and ferruling all ends

Replacing DIN rail components as required

Tidying the panel for easier maintenance

Updating all circuit labels

Providing post-repair electrical drawings

This instantly improves reliability and safety.

Damaged cables can cause:

Random stops

Incorrect length cutting

Misalignment

VFD trips

Intermittent faults

Motor power cables

Encoder cables (shielded)

PLC signal cables

Sensor cables

Hydraulic unit wiring

Decoiler control cables

Communication cables (CAN, Modbus, Ethernet, Profibus)

We also ensure correct shielding & grounding to eliminate noise issues.

When PLC modules fail, the machine will experience:

Dead sensor inputs

Solenoid valves not firing

Random alarms

No machine movement

Incorrect punching sequence

Identifying faulty PLC module

Installing replacement card (any brand)

Reconfiguring the system

Restoring or backing up machine programs

Testing each input/output point

Full diagnostic report

We support Siemens, Delta, Omron, Mitsubishi, Allen-Bradley, Fuji, Schneider, Weintek, and more.

Many imported machines come with:

Weak wiring

Cheap breakers

Incorrect grounding

Missing labels

Unsafe E-stop circuits

Our technicians can completely restore electrical reliability.

Replacing breakers, relays & contactors

Installing new terminal blocks

Rewiring 24V circuits

Strengthening grounding & bonding

Replacing safety relays

Cleaning, reorganizing, and relabeling panel

Installing surge protectors

Updating wiring schematics

This creates a safe, compliant, and serviceable electrical system.

When your roll forming line fails, every hour of downtime costs money. Machine Matcher offers:

UK, USA, Middle East & global coverage

24/7 callout availability

Same-day or next-day visits in many regions

Motor failures

VFD faults

Encoder/sensor failures

Safety circuit issues

PLC faults

Panel wiring problems

Cable damage

Hydraulic/electrical interlock issues

Full inspection report

List of root causes

Repair actions completed

Recommendations to prevent recurrence

Your machine returns to production quickly and safely.

✔ Specialists in roll forming machines only

✔ Fast diagnosis — minimal downtime

✔ Works with all brands, models & PLC types

✔ OEM-independent (we fix anything)

✔ Transparent pricing & documentation

✔ Highly skilled technicians around the world

✔ 24/7 remote support team

✔ Emergency site visits

Machine Matcher now offers full electrical technician services for roll forming machines — including diagnostics, rewiring, testing, encoder calibration, PLC programming, electrical audits, and preventive maintenance.

We support all machine types and all global regions.

Contact us today for immediate technical assistance or to schedule a full electrical inspection at your factory.

Looking for the right roll forming machine or expert guidance on your next project? Machine Matcher is here to help. Our global team provides 24/7 technical support, expert advice, and guidance on machine selection, setup, and maintenance—ensuring your operations run smoothly from day one.

With team members based worldwide—including the UK, USA, Middle East, and beyond—we are equipped to assist buyers across the globe. Whether you’re sourcing a single machine or upgrading an entire production line, our experts are ready to provide tailored solutions and support every step of the way.

Get in touch now and let Machine Matcher help you find the perfect roll forming machine for your business.

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.