Posted on Sunday, November 16, 2025

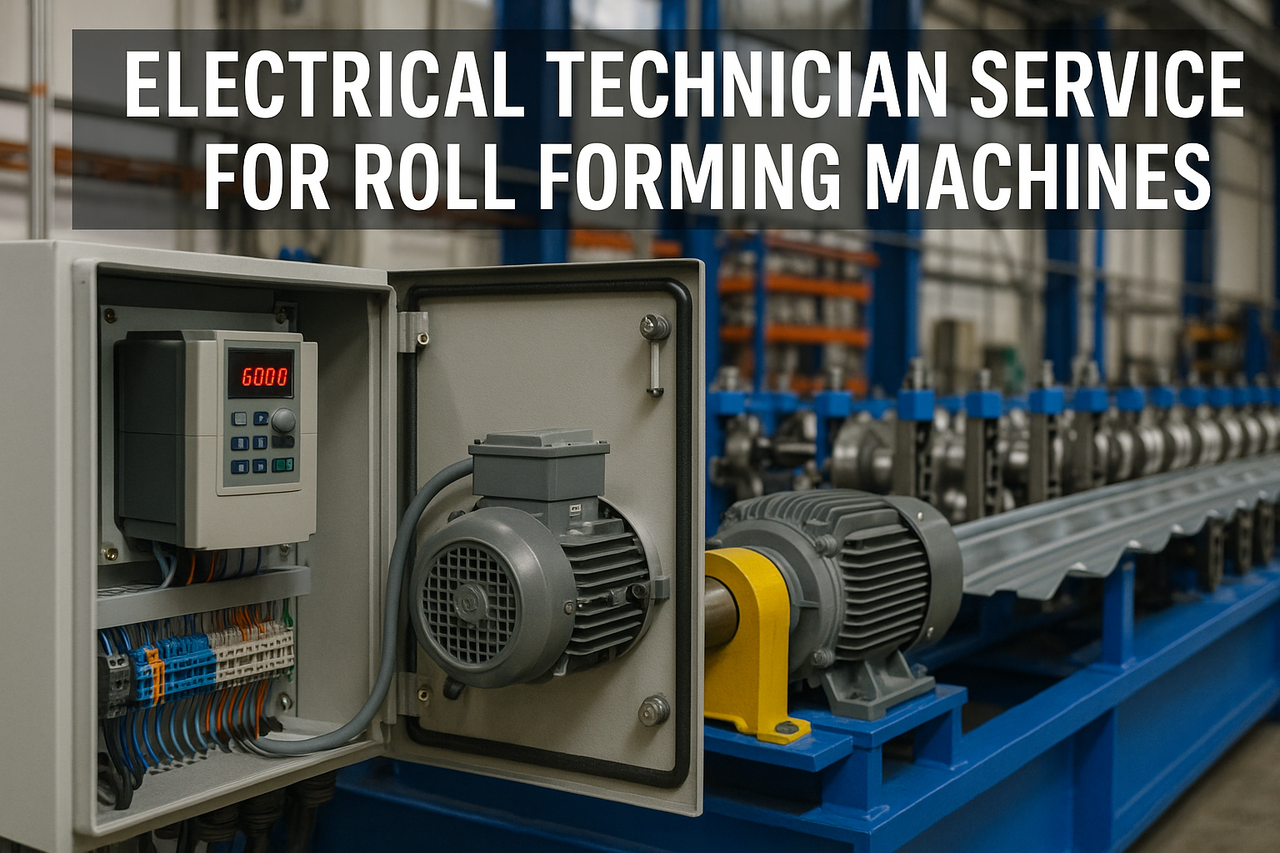

Electrical faults are one of the leading causes of downtime, poor panel performance, inaccurate profiles, and unexpected production stoppages in roll forming operations. To keep your lines running safely, accurately, and profitably, Machine Matcher now offers a dedicated Electrical Technician Service for Roll Forming Machines — designed specifically for roofing, purlin, decking, flashing, tube mill, and light-gauge framing equipment worldwide.

Our electrical specialists provide full diagnostics, maintenance, repairs, upgrades, and compliance assessments for every brand and model of roll forming machine. From PLC troubleshooting and encoder recalibration to full control-panel rewiring and on-site emergency repairs, we deliver fast, accurate, and OEM-independent support to ensure your machine performs exactly as it should.

Whether you need urgent electrical fault diagnosis, routine maintenance, safety checks, production optimisation, or long-term service contracts, our technicians combine real-world experience with advanced diagnostic tools to keep your machines running at peak performance. Every service includes a written report, risk assessment, and a step-by-step action plan to prevent future issues.

With global coverage, 24/7 remote support, and access to a network of certified electrical technicians, Machine Matcher provides the complete solution for maintaining and repairing the electrical systems that power your roll forming production.

Our goal is simple: reliable machines, reduced downtime, safer operations, and maximum production output—every single day.

Roll forming machines are electro-mechanical systems that rely on precise electrical coordination to operate safely and efficiently. Even small electrical issues can cause:

Length inaccuracy

Punching and notching misalignment

Flying saw crashes

Motor overload trips

PLC input/output faults

Servo position errors

VFD shutdowns and drive failures

Safety circuit lockouts

Slow production speed

Complete line stoppage

Because modern machines depend on PLC control, servos, encoders, proximity sensors, VFD drives, and safety relays, you need a trained electrical specialist who understands roll forming logic, not just general industrial wiring.

Machine Matcher provides that specialist.

We provide a complete electrical solution for all types of roll forming machines:

Fault diagnosis (I/O, scan time, logic errors)

Ladder logic updates

Addressing corrections

Safety circuit integration

PLC module replacement

Communication faults (RS485, CANbus, Modbus, Ethernet/IP)

VFD overcurrent, undervoltage, overload faults

Servo tuning & calibration

Flying saw synchronisation

Drive replacement & setup

Parameter backup & restoration

Encoder feedback verification

Proximity sensor replacement

Encoder recalibration

Limit switch adjustment

Photoelectric alignment

Noise-interference mitigation

Cable/connector replacement

Full motor testing (insulation, amp draw, phase balance)

Overload relay setup

Contactor replacement

MCC and electrical cabinet cleaning

Control panel rewiring

Grounding and earthing upgrades

Safety relay testing

Emergency stop verification

Guarding interlock checks

Electrical risk assessment

Certification documentation (country-specific)

Speed and cycle-time improvement

Error elimination

Reduced scrap rate

Improved cut-length accuracy

Punch timing refinement

Servo and VFD parameter optimisation

Machine Matcher can create a custom electrical maintenance plan, including:

Quarterly electrical inspections

Panel cleaning

I/O testing

Encoder and sensor replacements

Annual rewiring checks

Parameter backups

Emergency support priority

When your line is down, every minute counts.

We provide:

24/7 remote electrical support

Worldwide on-site technicians

Rapid diagnosis via video/PLC access

Emergency repair and component sourcing

Fast response. Minimum downtime. Safe restart.

Our electrical technicians service all major roll forming equipment:

(IBR, Corrugated, R-Panel, AG Panel, Standing Seam)

(Automatic size-change and manual systems)

(Composite deck, N-deck, deep deck)

(Stud & track)

We support every brand, including Chinese, U.S., European, and custom-built machines.

Every technician visit includes:

Full electrical checklist

Fault history analysis

PLC/VFD parameter backup

Encoder pulse verification

Sensor alignment

Motor electrical tests

Safety relay testing

Report with photos & recommendations

List of urgent and non-urgent issues

Production optimisation suggestions

Machine Matcher provides electrical technician services worldwide:

United States

United Kingdom

Canada

Europe

Middle East

Africa

Asia

Australia

South America

We use a network of certified roll forming technicians combined with our 24/7 online diagnostics system to deliver fast, accurate support anywhere in the world.

We work on all machine brands.

Our technicians understand PLC logic, flying saw sync, encoder scaling, cut-length feedback, and roll forming safety circuitry.

We use advanced tools and remote PLC/VFD access.

Technicians available on every continent.

We eliminate problems before they shut your machine down.

Clear explanations and actionable recommendations.

Whether you need:

Urgent fault repair

Full panel rewiring

PLC program corrections

Motor diagnostics

Encoder calibration

VFD/servo troubleshooting

Safety certification

Long-term maintenance support

Machine Matcher is ready to help.

Keep your roll forming machines reliable, accurate, and running at full productivity — every single day.

With team members based worldwide—including the UK, USA, Middle East, and beyond—we are equipped to assist across the globe.

Get in touch now and let Machine Matcher help you find the perfect roll forming machine for your business.

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.