Posted on Sunday, November 23, 2025

Electrical safety is one of the most overlooked areas in roll forming machinery — especially on imported machines where “minimum compliance” is the norm. Many factories receive machines with poor grounding, no RCD protection, weak E-stop circuits, and missing interlocks.

This guide covers the correct way to use RCD/GFCI protection and the essential safety hardware that every modern roll forming line should have.

Adding ground-fault protection can dramatically improve operator safety, but it must be used carefully.

Many factories install RCDs on the wrong circuits and end up with nuisance trips, especially when VFDs or servo drives are present.

Here’s the correct approach.

These outlets are used by engineers for:

Laptops

Test tools

Multimeters

Lights or portable tools

These MUST be protected by:

An MCB and

An RCD/GFCI (typically 30 mA)

This is required under modern electrical safety standards.

Low-power circuits that run without VFDs or high-frequency noise can safely use RCD protection.

Examples:

Panel lights

Control cabinet heaters

Small control transformers

Basic auxiliary circuits

These circuits benefit from ground fault protection without causing false trips.

A standard RCD cannot handle:

VFD switching noise

High-frequency leakage current

Harmonics

Normal earth leakage from drives

This results in nuisance tripping.

Correct approach:

If RCD is required (for compliance), use:

Type B RCD (for drives)

Or Type F RCD (for inverter-fed motors)

Correctly sized and engineered.

This must only be designed by a qualified industrial electrician or engineer.

✔ Use it on outlets

✔ Use it on small auxiliary loads

✔ Avoid it on VFD feeders unless properly engineered

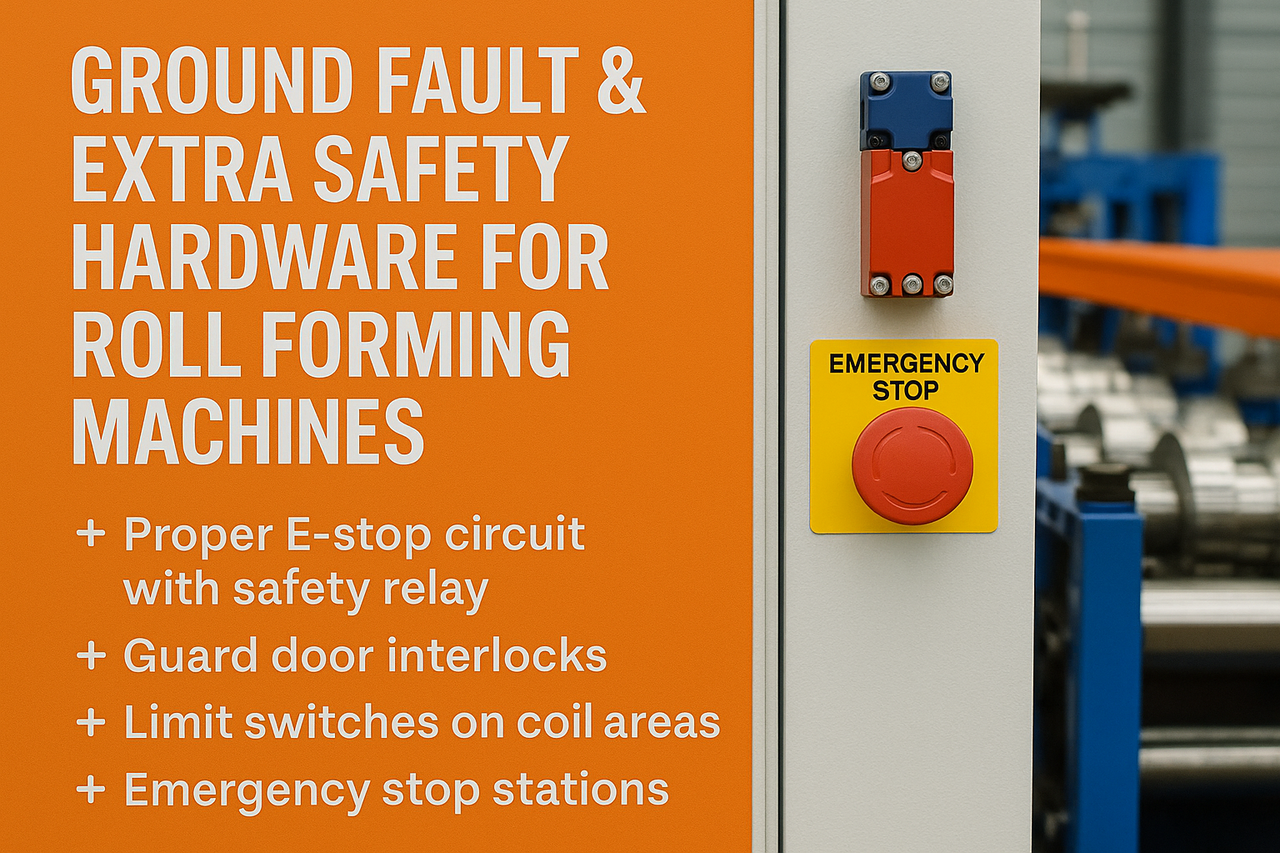

“Safety basics” are often missing from imported machines. The following hardware upgrades turn a risky machine into a compliant, safe, and efficient production line.

Most cheap machines use a single-channel E-stop loop — not compliant with CE/UKCA/OSHA.

Dual-channel E-stops (Category 3/4)

Wired through a certified safety relay

Relay must directly drop out:

Main contactors

Hydraulic pump motor

Drive contactor / STO (Safe Torque Off)

Feed motors

Prevents unexpected restart

Ensures the machine fully removes power

Allows monitored reset

Protects operators working near the cut-off area

A proper E-stop circuit is the foundation of machine safety.

Any guard that exposes moving parts MUST have a safety switch.

Electrical cabinet door

Gearbox covers

Chain guards

Decoiler pinch-roll area

Shear / cut-off area

Punching stations

Coded non-contact safety switches (RFID)

Or tongue-type interlocks with positive-opening contacts

Machine cannot run with guards open

No bypassing with magnets or tape

Compliant with CE/UKCA/OSHA safety levels

Limit switches prevent over-travel and dangerous movement.

Decoiler over-pay-out switch

Entry guide / pinch area safety limits

End-of-sheet detection

Stacker top travel limit

Conveyor travel limits

These switches prevent:

Material crashes

Hydraulic over-pressure

Damage to tooling

Operator injury

A roll forming line is long, and one E-stop at the operator panel is not enough.

✔ Operator control panel

✔ Decoiler area

✔ Cut-off / shear station

✔ Stacker / exit area

Large lines may need 6–10 E-stops.

If something goes wrong, operators must be able to stop the machine from any point along the line.

Roll forming lines are fast, powerful, and can be dangerous if safety circuits are not engineered to modern standards.

Every machine should have:

✔ Correct RCD/GFCI usage

✔ Modern dual-channel E-stops

✔ Proper safety relays

✔ Guard interlocks

✔ Travel limits & decoiler protection

✔ Multiple E-stop stations

✔ Correct breaker and wiring design

Factories that upgrade their electrical safety systems see:

40–70% fewer accidents

30–60% less downtime

Longer machine lifespan

Full compliance with CE/UKCA/OSHA

Machine Matcher provides:

Safety circuit upgrades

Guard interlock installation

Dual-channel E-stop rewiring

Type B RCD design for VFD systems

Full electrical panel safety audits

Wiring compliance upgrades

Limit switch installation

On-site or remote engineering support

Make your roll forming machine safe, compliant, and reliable — upgrade your safety hardware today.

Machine Matcher now offers full electrical technician services for roll forming machines — including diagnostics, rewiring, testing, encoder calibration, PLC programming, electrical audits, and preventive maintenance.

We support all machine types and all global regions.

Contact us today for immediate technical assistance or to schedule a full electrical inspection at your factory.

Looking for the right roll forming machine or expert guidance on your next project? Machine Matcher is here to help. Our global team provides 24/7 technical support, expert advice, and guidance on machine selection, setup, and maintenance—ensuring your operations run smoothly from day one.

With team members based worldwide—including the UK, USA, Middle East, and beyond—we are equipped to assist buyers across the globe. Whether you’re sourcing a single machine or upgrading an entire production line, our experts are ready to provide tailored solutions and support every step of the way.

Get in touch now and let Machine Matcher help you find the perfect roll forming machine for your business.

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.