Posted on Tuesday, November 11, 2025

Every roll forming machine relies on precise synchronization between material movement, cutting action, and control systems. At the heart of this synchronization is the encoder — a sensor that converts rotary motion into electrical signals that the PLC (Programmable Logic Controller) uses to determine the exact sheet length and cutting position.

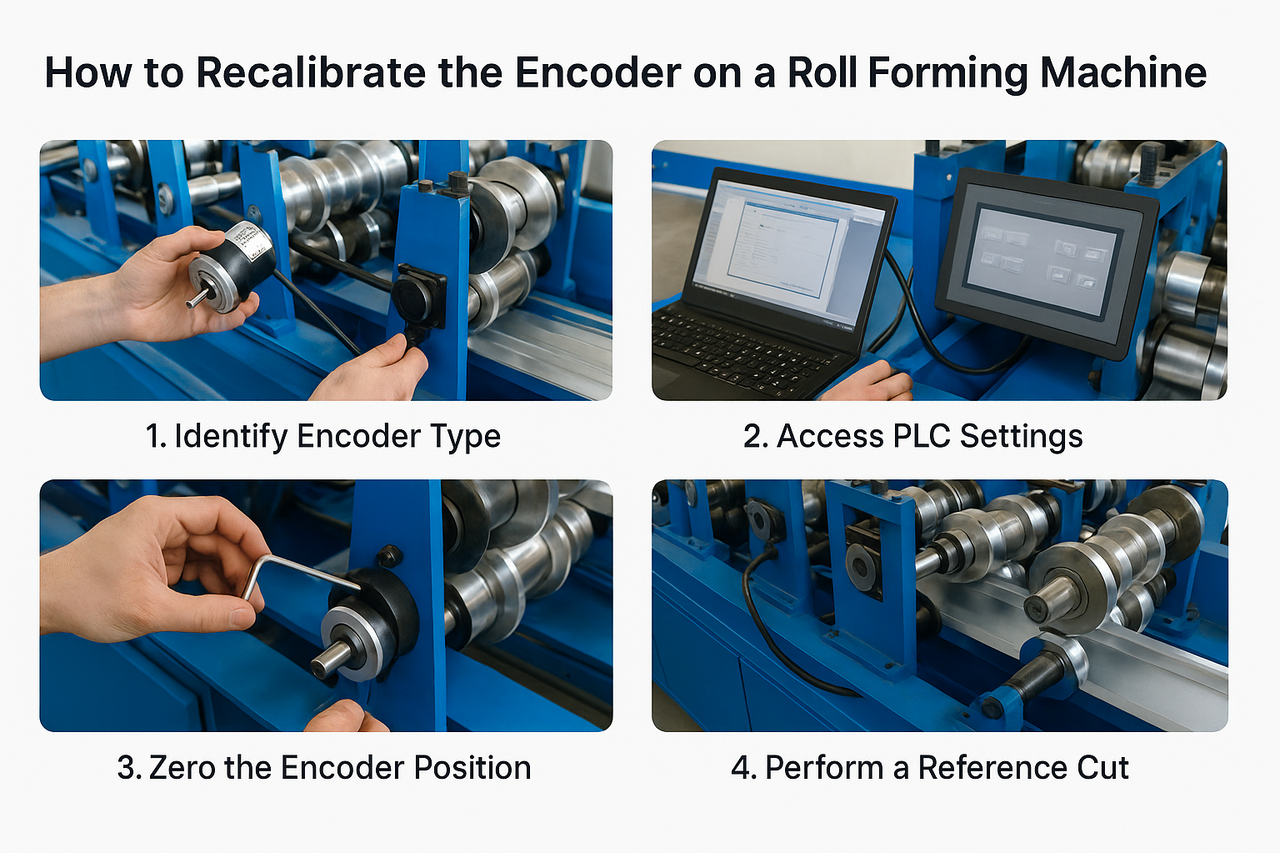

Over time, encoders can drift out of calibration due to wear, misalignment, or electrical noise, leading to cut length errors, wasted material, and production downtime. This guide will take you through a complete, step-by-step process for recalibrating your roll forming machine’s encoder safely and effectively.

In a roll forming machine, the encoder is typically mounted near the drive rollers or pinch rollers and is mechanically coupled to the line shaft or a driven roller. Its primary functions include:

Measuring line speed and distance traveled.

Synchronizing the flying shear cutter with the moving sheet.

Providing feedback to the PLC to control motor acceleration and deceleration.

If the encoder sends incorrect pulse counts, the PLC’s calculation of length becomes inaccurate, resulting in panels that are too long or too short.

Knowing when to recalibrate the encoder can prevent costly waste and downtime. Common symptoms include:

Panels consistently cutting short or long.

Inconsistent lengths across multiple runs.

Encoder or length fault alarms appearing on the HMI or PLC.

Errors appearing after maintenance or motor replacement.

Shear blade cutting before or after the intended position.

If any of these occur, recalibration or encoder inspection is likely needed.

Before any recalibration work begins:

Disconnect the main power supply.

Follow your facility’s lockout/tag-out procedures.

Ensure the encoder, cables, and coupling are clean and free from oil or debris.

Never perform encoder work while the line is moving.

Keep a backup of current PLC settings before making any changes.

You’ll need:

Multimeter (for voltage and continuity checks).

Laptop or HMI connected to the PLC.

Encoder datasheet (pulse count and wiring reference).

Allen keys and feeler gauge.

Calibration sheet or test coil.

Optional: Handheld tachometer for speed verification.

Check your encoder’s model and type. Encoders on roll forming machines are typically:

Incremental rotary encoders (most common).

Absolute encoders (used in advanced lines).

Magnetic or optical encoders (depending on environment).

Note the PPR (pulses per revolution) and voltage rating (often 5V or 24V). This is essential for correct scaling later.

Connect to your machine’s PLC system using the relevant software (e.g., Delta DOPSoft, Siemens TIA Portal, or Mitsubishi GX Works).

Locate parameters like:

Encoder input channel (e.g., X0–X3).

Scaling value or pulses-per-unit.

Length compensation or calibration offset.

Some HMIs have direct menus labeled “Length Calibration” or “Encoder Adjustment.”

Move the sheet or roller to the home or reference position.

Set the encoder value to zero in the PLC.

Ensure the encoder shaft and coupling are properly tightened.

Manually rotate the roller slightly to confirm smooth signal generation without spikes.

Run a single sheet at a known programmed length (e.g., 1000 mm).

Measure the actual length of the cut panel.

Example:

Programmed length = 1000 mm

Actual measured = 995 mm

→ Machine cutting short by 5 mm (0.5%)

Modify the encoder scaling value in the PLC or HMI settings.

Formula:

New scale = (Current scale × Programmed length) ÷ Actual length

Example:

If current scale = 1000 pulses per meter, and actual = 995 mm:

→ New scale = (1000 × 1000) ÷ 995 = 1005 pulses/meter.

Enter this adjusted value and save changes.

Perform another cut at the same programmed length.

Check if deviation is within ±0.5 mm or the manufacturer’s tolerance range.

If still off, repeat adjustment until precise.

Once accurate, record:

Final scale factor.

Date and operator name.

Encoder serial number and machine ID.

Reference cut results.

This documentation helps with future troubleshooting and compliance.

| Problem | Possible Cause | Solution |

|---|---|---|

| Panel cuts too long | Encoder pulses too low | Increase scale factor |

| Panel cuts too short | Encoder pulses too high | Decrease scale factor |

| Erratic readings | Loose shaft coupling or damaged cable | Tighten, replace cable |

| No feedback | Faulty 24V supply or signal wire break | Check voltage and continuity |

| Length varies at high speed | Electrical noise or interference | Use shielded cable and proper grounding |

In roll forming lines with flying shears, encoder feedback must remain synchronized between:

Main line encoder (measuring material speed).

Shear encoder (monitoring carriage movement).

If either encoder is miscalibrated, the cut may occur too early or late, causing burrs or panel deformation.

Always verify both encoders after recalibration and ensure PLC logic synchronization parameters (timing offset, acceleration curve) match the manufacturer’s recommended settings.

Clean the encoder lens or magnet every month.

Verify coupling tightness every 3 months.

Log calibration results in a maintenance logbook.

Check encoder cable insulation and connectors for corrosion.

Keep spare encoders in stock to avoid downtime.

Recalibrate every 6 months or after major mechanical work.

Recalibration may not solve persistent problems caused by:

Bearing wear inside the encoder housing.

Internal disc damage.

Signal noise despite correct wiring.

Encoders older than 5 years or showing intermittent faults.

Replacement is recommended when output becomes unstable, calibration fails repeatedly, or mechanical wear is evident.

Scenario:

A customer’s C/Z purlin roll forming line with a Siemens PLC started cutting panels 8 mm short at 12 m length.

Diagnosis:

Encoder feedback fluctuated at high speed.

Coupling found loose on drive roller shaft.

Fix:

Tightened coupling, recalibrated scaling, and verified 12 m cut accuracy to within ±1 mm.

Backed up new settings to PLC and maintenance file.

Machine Matcher offers full encoder support and calibration solutions for all roll forming machines, including:

Remote encoder recalibration via PLC access.

Encoder supply and replacement for most OEMs (Autonics, Omron, Delta, Baumer, etc.).

Flying shear synchronization checks.

Encoder-to-PLC pulse scaling assistance.

24/7 global technical support.

Our engineers can analyze your machine’s encoder signals remotely, identify signal noise or scaling errors, and send full calibration instructions or remote updates.

For complex systems, we also supply:

Ewon Cosy remote access devices.

Industrial cameras for real-time encoder monitoring.

Calibration report templates for quality records.

Q1: How long does encoder recalibration take?

Usually 20–30 minutes if you have proper access to the PLC and HMI.

Q2: Can encoder drift cause flying shear timing errors?

Yes. Incorrect encoder scaling desynchronizes shear motion, leading to miscuts or shear alarms.

Q3: Should encoder parameters be backed up?

Absolutely. Always save a copy of PLC settings before and after recalibration.

Q4: Can I recalibrate without shutting down the line?

For safety reasons, recalibration should only occur when the line is stopped and isolated.

Q5: How often should encoders be recalibrated?

Every six months or whenever cut length accuracy drifts beyond the tolerance range.

Q6: What is the difference between incremental and absolute encoders?

Incremental encoders output relative position via pulses; absolute encoders provide exact position, even after power loss.

Recalibrating the encoder on a roll forming machine is a crucial maintenance task that ensures dimensional accuracy, machine synchronization, and reliable production. By following the step-by-step procedure — from identifying encoder type to performing a reference cut — operators can restore proper function quickly and safely.

Regular calibration, proper documentation, and preventive maintenance are key to keeping your roll forming system performing at its best.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.