Posted on Sunday, November 16, 2025

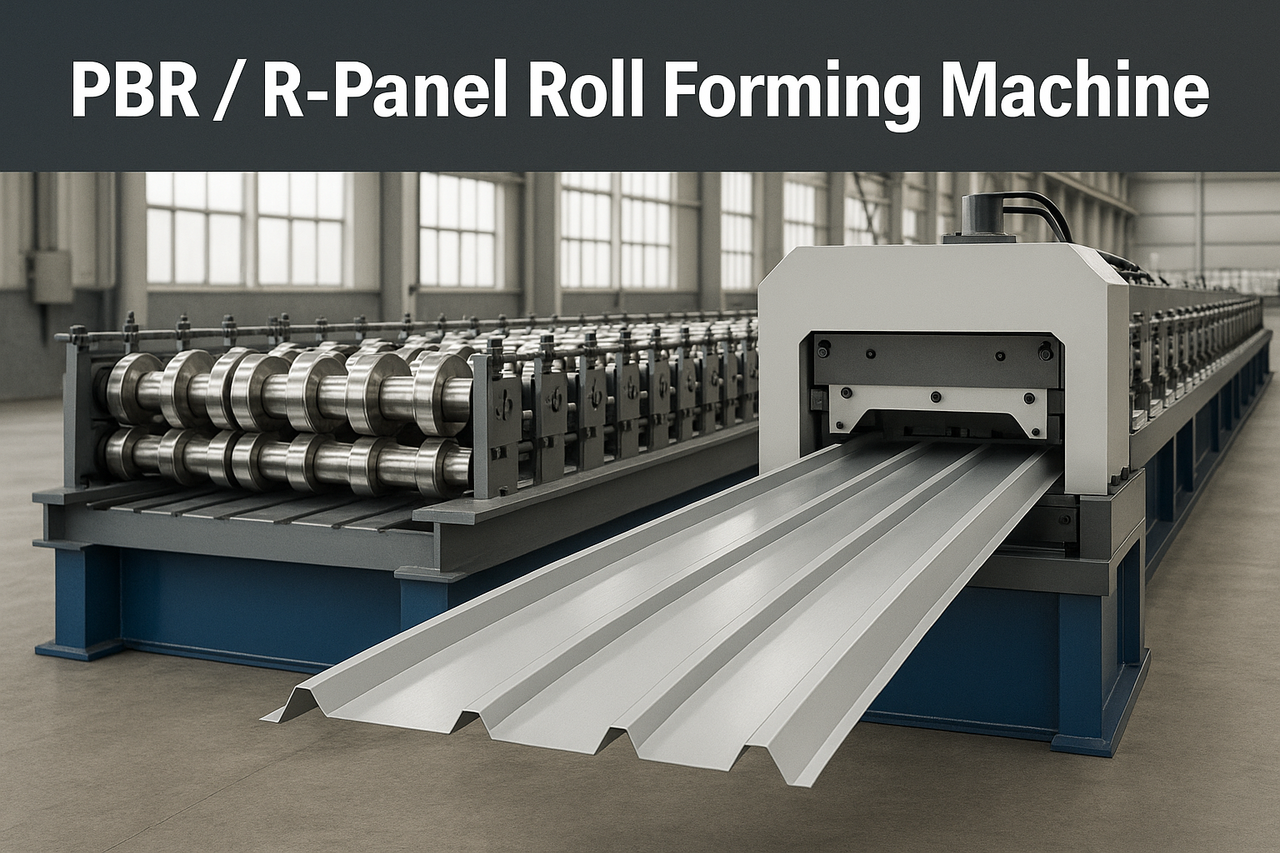

The PBR / R-Panel roll forming machine is one of the most widely used roofing and cladding production systems in North America, the Middle East, and emerging construction markets worldwide. Known for its strength, versatility, and broad application across industrial, commercial, agricultural, and residential sectors, the PBR (Purlin Bearing Rib) or R-Panel profile remains a market staple for steel building systems.

This complete guide covers everything a buyer, contractor, or factory owner needs to know before purchasing a PBR roll forming machine—from technical specifications and profile geometry to global usage, materials, power requirements, pricing, and installation. All machines supplied through Machine Matcher are built new, custom-configured, and delivered worldwide, with full support from our technical teams in the UK and USA.

A PBR / R-Panel roll forming machine is a fully automated production line designed to transform flat steel coil into a 36-inch metal panel with deep ribs and a bearing leg that sits over purlins. The classic PBR panel includes:

Three major ribs

Two minor ribs between each major rib

A purlin-bearing rib at one side for easier installation

Coverage width typically 36–38 inches

Rib height usually 1.00–1.25 inches

These machines are essential for building envelope systems due to the profile’s high structural strength and ability to span long distances with minimal support.

The machine feeds coil through a sequence of precisely machined rollers, gradually forming the rib shape without damaging the coating. A hydraulic or flying shear then cuts panels to length, controlled by an encoder and programmable PLC.

| Specification | Details |

|---|---|

| Machine_ID | MM-RPBR-001 |

| Machine_Family | Roofing Panel Roll Forming Line |

| Machine_Type | PBR / R-Panel Roll Forming Machine |

| Alternate_Names | R-Panel Machine, PBR Roofing Machine, 36” Roofing Panel Machine |

| Region_Popularity | USA, Canada, Mexico, Brazil, UAE, Saudi Arabia, Australia, South Africa |

| Common_Profiles_Produced | 36” PBR, 36” R-Panel, deep rib R-panel, reverse R-panel |

| Gauge_Range_mm | 0.30–0.80 mm (29–22 gauge) |

| Material_Types | GI, GL, PPGI, PPGL, Aluminum |

| Tensile_Range_MPa | 235–550 MPa |

| Production_Speed_mpm | 12–45 m/min |

| Roller_Stations | 16–24 stations |

| Roller_Material | GCr15 / 45# Steel (heat-treated & chrome-plated) |

| Shaft_Material | 40Cr hardened shafts (60–75 mm) |

| Cutting_Type | Hydraulic guillotine (standard), Flying shear optional |

| Punching_Type | Hydraulic or servo punching (optional) |

| Power_Supply | 380V–415V 50Hz / 230–480V 60Hz |

| Motor_Power_kW | 7.5–15 kW |

| Hydraulic_Power_kW | 4–7.5 kW |

| Control_System | Siemens / Mitsubishi / Delta PLC & HMI |

| Automation_Level | Fully automatic |

| Line_Configuration | Decoiler → Feeder → Forming → Cutting → Table |

| Coil_Width_Range_mm | 914–1220 mm |

| Coil_Thickness_Range | 0.30–0.80 mm |

| Accessories_Included | 3–5 ton decoiler, run-out table, spare blades |

| Optional_Extras | Coil car, hydraulic decoiler, flying shear, stacker, remote PLC, embossing |

| Typical_Applications | Roofing, wall cladding, barns, warehouses, sheds |

| Industries | Construction, steel buildings, agriculture, warehousing |

| Common_Countries | USA, Canada, Mexico, UAE, South Africa, Brazil, Australia |

| Price_Range_USD | $38,000 – $160,000 |

| SEO_Keywords | PBR machine, R-panel roll former, metal roofing machine |

| SEO_Tags | metal roofing, roll forming, steel panel |

| Notes | High demand in USA & Gulf region; profile variations exist |

4. PBR / R-Panel Profile Overview

The PBR profile is a heavy-duty metal panel used for both roofing and siding. It offers superior load-bearing performance due to its deep ribs, consistent geometry, and purlin-bearing leg.

Coverage width: 36 inches (914 mm)

Rib height: 1.00–1.25 inches

Major rib spacing: 12 inches

Material thickness: 29–22 gauge

Materials: GI, GL, PPGI, PPGL, Aluminum

Strong, rigid, high-spanning capability

Works for low, medium, and high roof pitches

Excellent durability in harsh climates

Compatible with insulation systems

Easy installation due to the bearing leg

Texas deep-rib PBR

Gulf-region box rib

Reverse R-panel for wall siding

PBR with vented or punched ribs

The machine transforms coil into panels using these stages:

The coil is loaded onto a manual or hydraulic decoiler. Tension is controlled to avoid coating scratches.

A pinch or servo feeder aligns the strip before forming.

16–24 stations progressively shape the ribs:

Minor ribs

Major ribs

Bearing leg

Side lock (if included)

Tooling is hardened and polished to prevent damage to painted or galvanized surfaces.

Encoder monitors the strip and sends signals to the PLC for precise lengths.

Hydraulic or flying shear cuts panels at programmed lengths without deforming the profile.

Finished panels exit onto a run-out table or automatic stacker.

The PBR panel is used in:

Industrial warehouses, factories, farm buildings, and storage centers.

Commercial buildings, retail units, workshops, garages.

Barns, sheds, feed storage, horse arenas.

Carports, porches, siding, fencing panels.

Construction

Steel building manufacturers

Agricultural building suppliers

Oil & gas service centers

Warehousing and logistics

DIY metal building suppliers

Pre-engineered steel buildings

The world’s most dominant PBR region. Used in roofing, wall systems, barns, and steel buildings.

Popular due to strength in hot climates and strong wind load resistance.

Demand increasing due to affordability and robustness.

Heavy use for industrial and agricultural construction.

Used in wide-span structures and metal sheds.

$38,000 – $85,000

(Manual decoiler, hydraulic cutter, 12–18 m/min speed)

$85,000 – $120,000

(Automatic decoiler, improved speed, chrome-coated rollers)

$120,000 – $160,000

(Flying shear, servo feeder, automatic stacker, 40+ m/min)

Shipping & logistics

Import duties

Installation & commissioning

Profile tooling customization

Spare parts & consumables

Hydraulic decoiler (3–10 tons)

Coil car automatic loading

Scrap shear

Flying shear system

Automatic panel stacker

Embossing rollers

Remote PLC (Ewon, Siemens)

Safety guard enclosure

Auto-lubrication system

18–24 meters space

380–480V 3-phase

Flat concrete floor

Overhead crane or forklift for coils

Install the line

Align roller stations

Test electrical & hydraulic connections

Run initial coil

Fine-tune profile forming

Production ramp-up

Daily:

Clean rollers

Check hydraulic levels

Inspect encoder sensor

Weekly:

Lubricate chains & bearings

Check gearbox oil

Inspect cut blades

Monthly:

Tighten bolts

Flush hydraulic tank (if required)

Backup PLC program

36 inches coverage.

GI, GL, PPGI, PPGL, aluminum.

26–29 gauge for roofing, 24–22 gauge for structural walls.

Siemens, Mitsubishi, Delta.

230V–460V, 60Hz, 3-phase.

12–45 m/min depending on configuration.

Yes, with alternate tooling.

Yes, hydraulic or servo punching can be integrated.

Yes—worldwide installation and training.

No—all tooling is polished and hardened.

Yes, reverse R-panel is common for walls.

8–12 years depending on material and maintenance.

Yes, Machine Matcher can design any profile.

Typically $150–$300.

Yes—24/7 remote PLC and electrical support is available.

Machine Matcher supplies brand-new roll forming machines engineered to your exact specification.

We offer:

Custom profiles

Worldwide delivery

Installation and training

24/7 remote technical support

Electrical diagnostics

Profile design assistance

Spare parts

PLC programming help

Contact Machine Matcher

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.