Posted on Friday, November 21, 2025

When buying a new roll forming machine — whether from a local manufacturer or an overseas supplier — the electrical system is the most important part of the build. A machine can have perfect rollers, strong frames, and good hydraulics, but if the electrical panel is poorly designed, you will experience:

Random machine stops

Unsafe operation

VFD trips

Incorrect cut lengths

Electrical noise

Sensor failures

Overheating

Difficult maintenance

Compliance issues (CE, UL, UKCA)

The problem? Many suppliers provide the bare minimum electrical configuration unless you specify exactly what you require.

This blog gives you a practical, ready-to-send checklist that tells your electrician or supplier exactly what your roll forming line must include.

You can literally copy and paste it into your order email.

Factories lose thousands each year due to machines that are shipped with:

Under-rated breakers

Cheap sensors

Weak control power supplies

Incorrect grounding

No surge protection

Unprotected motors

Unsafe E-stop circuits

Missing documentation

By telling your supplier what you want up front, you ensure:

✓ Safer operation

✓ Longer machine life

✓ Faster troubleshooting

✓ Better performance

✓ Lower scrap rate

✓ Full electrical compliance

Below is the exact message you can send:

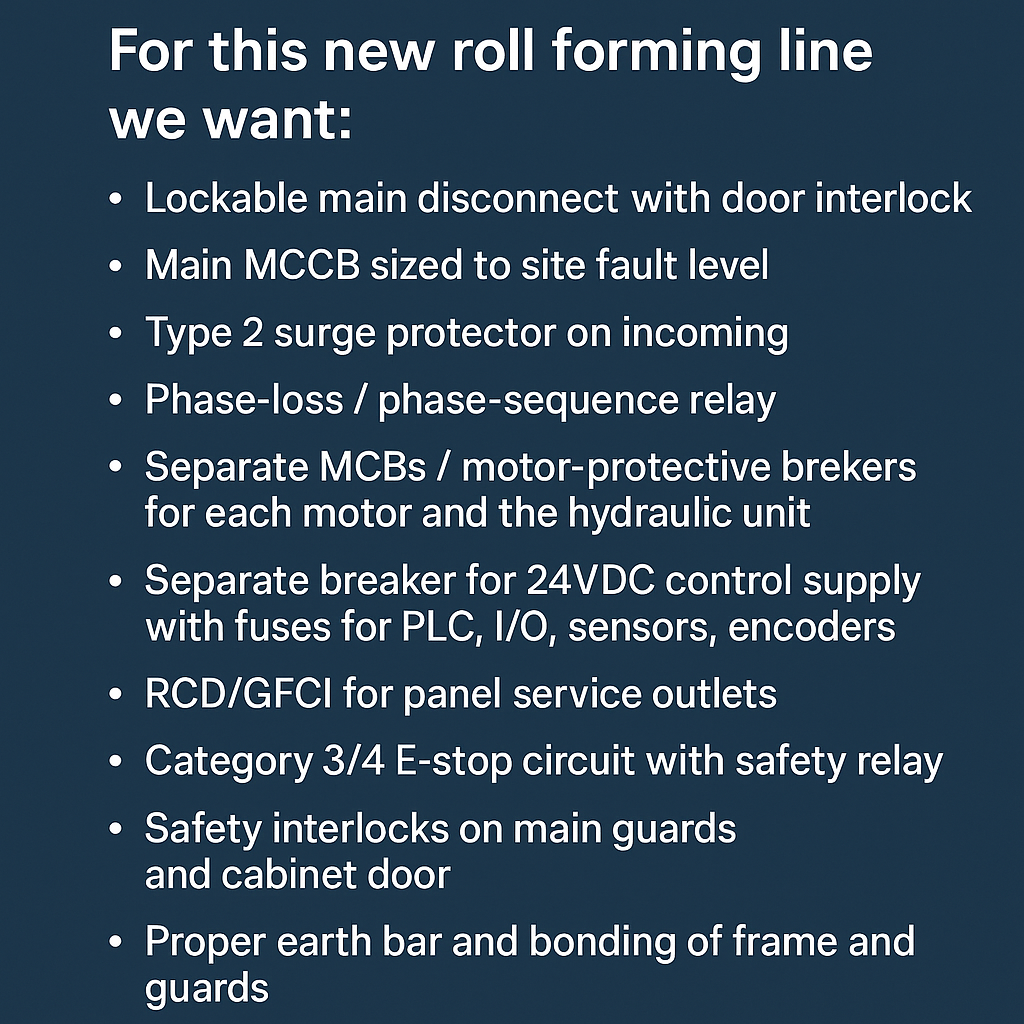

“For this new roll forming line we want:

• Lockable main disconnect with door interlock

• Main MCCB sized to site fault level

• Type 2 surge protector on incoming supply

• Phase-loss / phase-sequence relay

• Individual MCBs or motor-protective breakers for each motor and the hydraulic unit

• Separate breaker feeding 24VDC control supply with fused outputs for PLC, I/O, sensors, encoders

• RCD/GFCI for panel service outlets

• Category 3/4 E-stop circuit with safety relay

• Safety interlocks on main guards and cabinet door

• Proper earth bar and full bonding of frame, guards, motors, and panel door

• Panel drawings updated to match final wiring”

Below is the explanation behind each requirement — useful for educating factory owners, operators, and suppliers.

Prevents the machine from being powered while the panel is open.

Required for: Safety, CE, UKCA, UL, OSHA compliance.

If the machine’s breaker cannot handle your factory’s available fault current, it may not trip during a fault — creating a fire risk.

Factories with strong 3-phase supply MUST request this.

Protects against:

Lightning

Grid instability

Nearby welders/compressors

Stops VFDs and PLCs from burning out.

Prevents:

Reverse motor rotation

Motor overheating

VFD faults

Hydraulic pump damage

Essential for machines shipped internationally.

Each motor (main drive, hydraulic pump, decoiler, etc.) must have its own breaker or motor-protective device.

Benefits:

Better overload protection

Easy fault isolation

Safer maintenance

The heart of your machine.

Needs:

Dedicated breaker

Fused outputs

Clean grounding

Prevents “mystery faults” like:

Sensor flicker

Encoder pulse loss

PLC resets

Protects maintenance engineers using tools near the panel.

Often forgotten by OEMs.

Stops machine immediately and safely.

Dual-channel and monitored.

Prevents:

Unsafe restart

Guard bypassing

False safety resets

Required by all major standards.

Ensures machine cannot run unless:

Guards are closed

Panel door is locked

Reduces injury risk dramatically.

Correct grounding prevents:

Electrical noise

Encoder instability

PLC glitches

Electric shock hazards

Most imported machines do this incorrectly.

If the drawings don’t match the build, maintenance becomes nearly impossible.

Technicians need:

Updated schematics

Terminal layout

I/O list

VFD/servo parameters

Machine Matcher provides these in every job.

Send it to your supplier before the machine is built, ideally at the quote or design stage.

If buying used machines, send it to your electrician during refurbishment.

This ensures:

Correct panel build

Electrical compliance

No surprise costs

Fast troubleshooting

Safer long-term operation

Machine Matcher provides:

Full electrical panel inspection

Compliance check (CE / UKCA / OSHA / UL)

Safety relay & interlock testing

Breaker & grounding verification

Wiring quality audit

Sensor & encoder evaluation

VFD/PLC electrical assessment

Rebuild or upgrade recommendations

Written report and photos

24/7 global technical support

Send this checklist to your supplier — and let Machine Matcher make sure your machine is built safely, correctly, and ready for long-term high-speed production.

Machine Matcher now offers full electrical technician services for roll forming machines — including diagnostics, rewiring, testing, encoder calibration, PLC programming, electrical audits, and preventive maintenance.

We support all machine types and all global regions.

Contact us today for immediate technical assistance or to schedule a full electrical inspection at your factory.

Looking for the right roll forming machine or expert guidance on your next project? Machine Matcher is here to help. Our global team provides 24/7 technical support, expert advice, and guidance on machine selection, setup, and maintenance—ensuring your operations run smoothly from day one.

With team members based worldwide—including the UK, USA, Middle East, and beyond—we are equipped to assist buyers across the globe. Whether you’re sourcing a single machine or upgrading an entire production line, our experts are ready to provide tailored solutions and support every step of the way.

Get in touch now and let Machine Matcher help you find the perfect roll forming machine for your business.

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.