Posted on Saturday, January 10, 2026

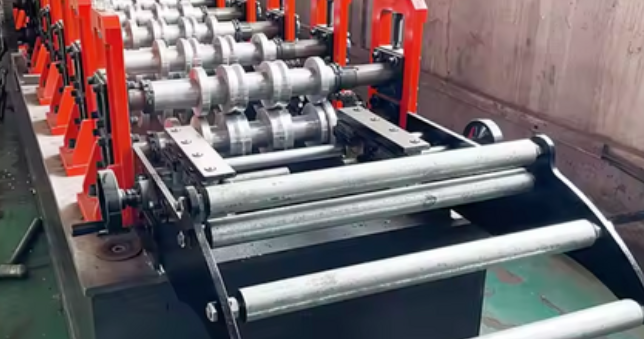

Machine Matcher sources and delivers custom-built wall cladding panel roll forming machines for manufacturers worldwide. Wall cladding panels are widely used for commercial, industrial, architectural, and agricultural buildings, providing durability, weather protection, and modern design flexibility.

We match your exact wall cladding profile, materials, and production requirements to the right machine — and manage the entire process from order to delivery.

All wall cladding panel roll forming machines are new, built to specification, and shipped globally with secure payment handling, controlled fund release, and full import support.

A wall cladding panel roll forming machine is designed to produce metal wall panels used for exterior and interior building envelopes. These panels can be structural or non-structural, decorative or functional, depending on the application.

Wall cladding systems are commonly used for:

Industrial and commercial buildings

Warehouses and logistics facilities

Architectural façades

Agricultural and storage buildings

Interior wall linings and partitions

Profiles vary widely by region, aesthetic preference, and performance requirements.

Machine Matcher supplies wall cladding machines for a wide range of profiles, including:

Trapezoidal wall cladding panels

Box profile wall panels

Ribbed wall cladding systems

Flat and micro-rib façade panels

Liner panels (internal wall cladding)

Insulated panel outer skins

Custom wall cladding profiles based on customer drawings

Machines are built to match regional standards or fully custom designs.

Machine Matcher acts as your procurement and project partner, not just a machine supplier.

Submit Your Wall Cladding Profile & Requirements

Share your profile drawing, panel width, rib geometry, material type, gauge range, surface finish, and required production speed.

Machine Matching & Quotation

We source the right manufacturer and issue a clear quotation covering machine configuration, cutting system, lead time, and delivery.

Secure Payments & Production Control

Payments are made to Machine Matcher and released to the manufacturer in stages as agreed production and inspection milestones are met.

Inspection, Shipping & Delivery

Machines are tested prior to shipment, documented correctly for customs, and delivered to your facility.

To reduce risk when purchasing overseas wall cladding machinery, Machine Matcher uses a controlled, milestone-based payment structure.

30% deposit to begin production

70% balance due after inspection and before shipment

50% at order confirmation

50% prior to shipment

The commercial invoice for customs is issued by the manufacturer directly to the buyer and reflects machine value only. Brokerage and coordination services are invoiced separately and are non-dutiable.

Machine Matcher supplies wall cladding panel roll forming machines worldwide, including:

United States & Canada

United Kingdom & Europe

Middle East

Africa

Asia-Pacific

South America

Buyers remain the Importer of Record, and we support shipping and documentation to ensure clean, compliant imports in each region.

Wall cladding machines supplied by Machine Matcher can be configured to produce:

Exterior metal wall cladding panels

Interior liner panels

Architectural façade panels

Vertical and horizontal cladding systems

Insulated panel outer skins

Custom wall cladding designs

Machines are built to your exact profile geometry, tolerances, material type, and gauge range.

Wall cladding panel roll forming machines can be configured to process:

Galvanized steel (GI)

Galvalume / Aluzinc

Pre-painted steel (PPGI / PPGL)

Aluminum

Stainless steel (application-dependent)

Typical gauge ranges:

0.35 – 1.0 mm (profile-dependent)

Exact capability depends on panel depth and machine specification.

Wall cladding panel roll forming machines are widely used across industries including:

Metal wall cladding manufacturers

Commercial and industrial construction

Architectural and façade contractors

Steel building system suppliers

Agricultural and storage building manufacturers

These machines support both high-volume production and custom architectural applications.

Secure, controlled payment handling

New machines built to specification

Vetted global manufacturers

Clean customs and import compliance

Global delivery coordination

Ongoing technical and after-sales support

Upload your wall cladding panel profile drawing or share your production requirements, and Machine Matcher will match the right wall cladding panel roll forming machine for your application.

👉 Request a Wall Cladding Panel Machine Quote

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.