To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

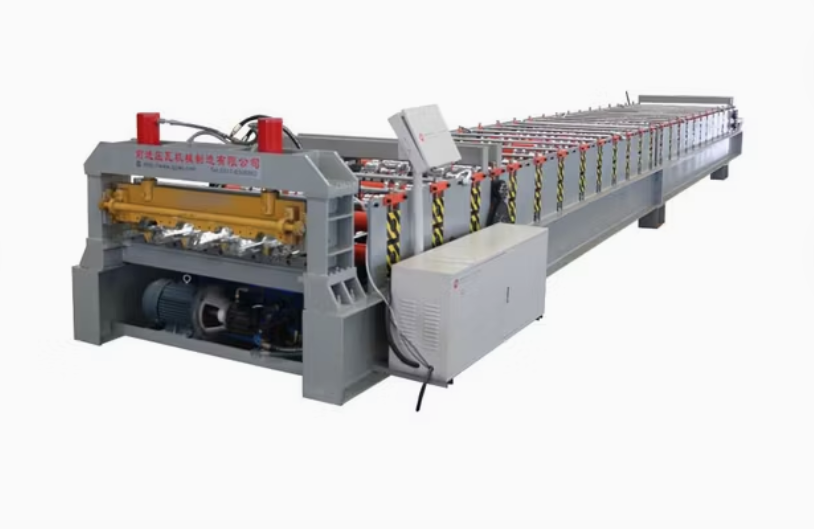

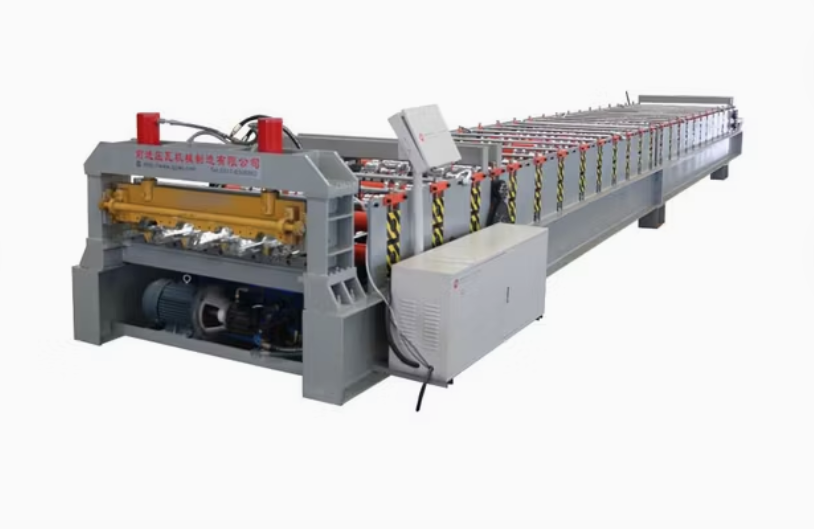

1.5” Composite Floor Deck Roll Forming Machine – UAE Specification and Full Product Description

Overview

The 1.5” Composite Floor Deck Roll Forming Machine is a high-precision, heavy-duty industrial solution for producing composite metal deck panels commonly used in commercial and industrial concrete flooring systems. Engineered for strength and durability, this machine is tailored to meet the structural needs of UAE construction projects, offering fast and accurate production of steel decking with shear bond-enhancing embossments.

This roll forming line is fully automated and designed for medium to large-scale steel construction fabricators, developers, and contractors across the UAE—including major cities like Abu Dhabi, Dubai, and Sharjah. It helps streamline slab floor systems used in high-rise buildings, bridges, parking structures, shopping malls, and industrial facilities.

All machines are new, custom-built, and shipped directly from our global manufacturing partners to customers across the United Arab Emirates.

Machine Type: 1.5” Composite Floor Deck Roll Forming Machine

Production Speed: 10–20 meters per minute (adjustable)

Material Thickness Range: 0.8 – 1.5 mm

Material Width Range: 1000 – 1250 mm (coil input)

Material Types: Galvanized Steel (GI), Galvalume, Cold Rolled Steel

Material Yield Strength: Up to 550 MPa

Roller Material: GCr15 (heat-treated and chrome-coated for wear resistance)

Roller Surface Treatment: Hard chrome plating

Number of Forming Stations: 24–32 (depending on final profile complexity)

Roller Shaft Diameter: 75 mm

Shaft Material: High-grade forged steel (quenched and tempered)

Main Drive Type: Chain Drive / Gear Drive (optional upgrade)

Motor Power (UAE configuration): 15–22 kW, 3 Phase, 415V / 50Hz

Power: Designed for UAE’s 415V 50Hz grid

Cutting Method: Hydraulic cutting (non-stop shearing)

Blade Material: Cr12MoV (hardened, wear-resistant)

Control Type: PLC system (Delta/Siemens) with touchscreen HMI

Operating Mode: Automatic and Manual Modes

De-coiling System: Hydraulic uncoiler with coil car (5–10 Ton capacity)

Punching/Notching System (if included): Optional embossing or shear stud guides

Machine Frame: Welded steel frame, stress-relieved

Thickness of Frame Steel: 20–30 mm steel sidewall structure

Profile Shape: 1.5” Composite Floor Deck (with ribs, embossments, shear keying)

Profile Width and Depth: 915–1000 mm effective coverage, 38 mm (1.5”) depth

Length Tolerance: ±1.0 mm per 10 meters

Protective Covers/Guards

Emergency Stop Button

Overload Protection System

Interlocked Access Panels (optional)

This machine is essential for:

Commercial & Industrial Construction

High-rise Residential Towers

Office Complexes

Warehouses & Factories

Parking Structures & Bridges

Pre-engineered Building (PEB) Systems

Composite floor decking enhances fire resistance, increases load-bearing capacity, and reduces slab thickness—making it a preferred system in the UAE’s fast-paced construction industry.

Prices start from: USD 85,000 – USD

What affects the final price:

Coil width and thickness range

Embossing unit and hydraulic punching (optional)

Automatic stacker

PLC brand and automation level

Local customization requirements (power configuration, logo, color, etc.)

All machines are new and custom-built to match your profile drawing and technical needs.

Delivery: Anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and other emirates.

Warranty & Support:

1-year warranty from date of dispatch. Ongoing technical support and remote assistance included.

If you have a profile drawing or technical requirement, please send it to:

📧 [email protected]

Our technical team will respond quickly with a tailored quote.

Q1: Can this machine produce custom composite floor deck profiles?

Yes, the machine is fully customizable based on your required profile drawing.

Q2: What power system is it built for in the UAE?

Standard machines are configured for 415V / 50Hz / 3-phase, which matches UAE industrial standards.

Q3: What is the estimated delivery time?

Typical production time is 60–90 days, plus international shipping to the UAE.

Q4: Can it include an automatic stacker?

Yes, optional extras include automatic stackers, coil cars, and embossing units.

Q5: Is installation and training offered?

Yes, Machine Matcher can coordinate remote setup support, and on-site training is available on request.

Q6: Is this machine suitable for Dubai's high-rise market?

Absolutely. The 1.5” composite floor deck profile is widely used in multi-story buildings and large-scale commercial developments in the UAE.

For expert help choosing the right machine, contact our team at Machine Matcher—your trusted roll forming equipment partner in the UAE and beyond. Would you like a sketch or technical drawing of the 1.5” floor deck profile included as well?

Copyright 2026 © Machine Matcher.