To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

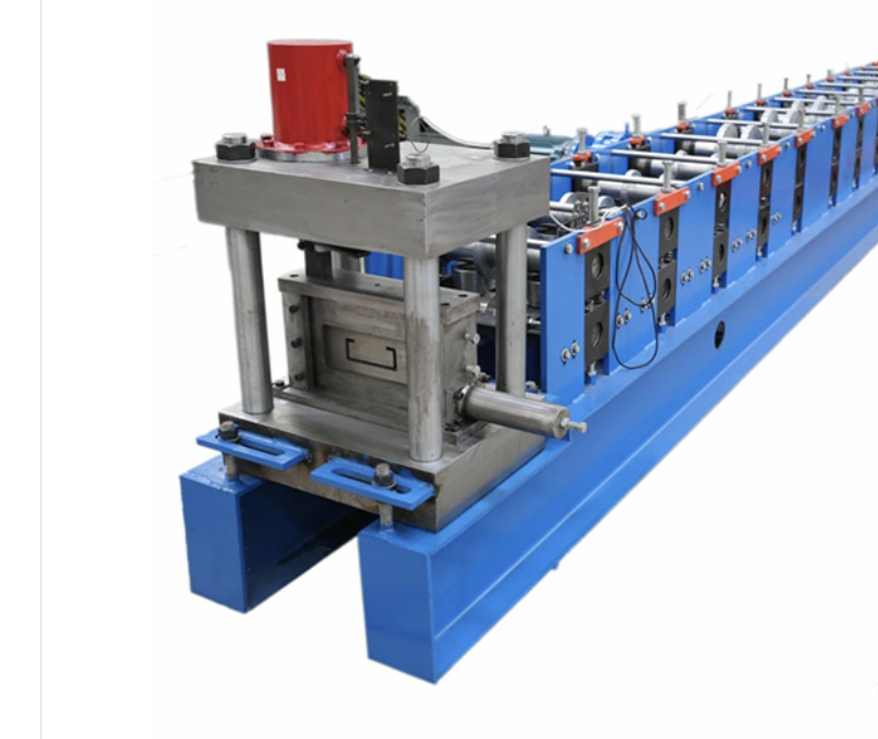

This is a new product line to produce C-purlin with pre-punching and post cutting, the panel have a wonderful aspect, punching holes are available as your particular requirement. C-purlin line can manufacture several types, such as C80 C100 C120 C140 C150 C160 C180 C200 C250 etc, the panel has high intension, reasonable design and easily installation, also have a strong economy benefit.

Un-coier, pre-leveling device, pre-punching, roll forming machine, post cutting device, PLC control system, Product rack.

2 Main motor power4kw, 3 phase

3 Hydraulic motor power3kw

4 Hydraulic Pressure10-12MPa

5 Voltage380V /3phase/ 50 HZ (or as your requirement)

6 Control SystemPLC Delta Inverter

7 Main Frame300mm H-Beam or 350mm

8 Backboard Thickness14mm

9 Chain Size20mm

10 Feeding Materialcolor steel coils

11 Feeding Thickness0.25-0.4mm

12 Feeding Width 500mm

13 Effective width 312mm

14 Productivity8-12m/min

15 Roll Station14 roll steps(according to different design)

16 Roller Diameter70mm(depend on different design)

17 Roller material 45# steel

18 Cutter materialCr12 , quenched

19 Cr-Plating Size0.05mm

20 Overall Size7500×1400×1500mm

21 Total Weight4.0T

The 100-350mm Automatic C Purlin Roll Forming Machine is designed for high-efficiency production of C purlins, which are essential components in construction and structural applications. Here are some key features and specifications of this machine:

This roll forming machine not only improves production efficiency but also ensures the consistent quality of C purlins, making it a valuable asset for manufacturers in the construction industry. If you have specific requirements or need further information, feel free to ask!

Copyright 2026 © Machine Matcher.