To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

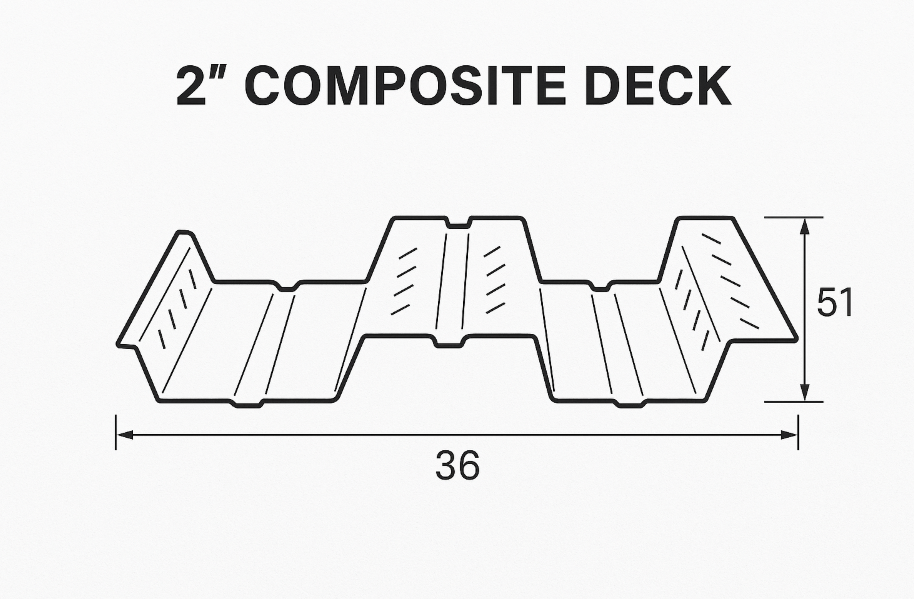

2" Composite Deck Roll Forming Machine – UAE Edition

Premium Structural Decking Solution for the UAE Construction Sector

The 2" Composite Deck Roll Forming Machine is a high-performance, precision-engineered machine designed to produce structural composite metal decking panels widely used in commercial, industrial, and high-rise residential construction. With robust construction and advanced automation, this machine delivers consistent quality, speed, and reliability for demanding UAE-based projects.

Optimized for the UAE’s rapidly growing infrastructure and construction markets, the 2” composite deck profile offers excellent tensile strength and concrete bonding properties, making it ideal for composite floor slab systems in buildings and bridges. This machine is custom-built and shipped directly to customers across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

All machines are new and custom-built to meet exact profile requirements and include a 1-year warranty from dispatch, with full maintenance and repair support.

This roll forming machine is built for the construction and infrastructure sectors, serving industries such as:

High-Rise Commercial Construction

Industrial Warehouses

Bridge Decking

Parking Structures

Stadium and Airport Construction

The 2” composite deck panels produced by this machine are designed to work in tandem with concrete slabs, reducing steel usage, acting as permanent formwork, and improving load-bearing performance.

| Specification | Details |

|---|---|

| Machine Type | 2" Composite Deck Roll Forming Machine |

| Production Speed | 12–20 meters per minute (adjustable) |

| Material Thickness Range | 0.8 mm – 1.5 mm |

| Material Width Range | 1000 mm – 1300 mm (depending on profile) |

| Material Types | Galvanized Steel, Galvalume, Cold Rolled Steel |

| Material Yield Strength | Up to 550 MPa |

| Roller Material | GCr15 (high-grade bearing steel) |

| Roller Surface Treatment | Hard chrome coating for corrosion resistance |

| Number of Forming Stations | 24–28 (depending on profile design) |

| Roller Shaft Diameter | 80 mm solid shafts |

| Shaft Material | 45# steel, precision ground and quenched |

| Main Drive Type | Gearbox-driven for heavy-duty operation |

| Power (UAE compatible) | 380V / 50Hz / 3Phase |

| Motor Power | 15 kW main motor |

| Cutting Method | Post-cut with hydraulic cutting system |

| Blade Material | Cr12Mov (heat-treated) |

| Control Type | PLC Control System (Siemens or Delta) |

| Operating Mode | Automatic with touchscreen interface |

| De-coiling System | 5–10 Ton Hydraulic Uncoiler (optional automatic tension control) |

| Punching/Notching System | Optional servo punching unit for shear connectors or end lugs |

| Machine Frame | Welded H-Beam or heavy-duty steel frame |

| Thickness of Frame Steel | 20–25 mm |

| Profile Shape | 2” Composite Deck (trapezoidal profile with embossments) |

| Profile Width and Depth | Approx. 950–1200 mm net width x 51 mm depth |

| Length Tolerance | ±1.5 mm |

Protective Covers/Guards on moving parts

Emergency Stop Buttons placed at strategic points

Overload Protection System for motors and hydraulics

Operator Alert Systems for faults and jam detection

Automatic Stacker for panel output

Servo-Driven Punching Unit for end-lap or shear stud holes

Remote PLC Monitoring and Diagnostic System

Coil Car for hydraulic loading

Pre-leveling Unit for coil straightening

Starting Price: From USD $85,000

Note: Final pricing is determined based on:

Profile design complexity

Number of forming stations

Optional extras (stacker, punching, uncoiler, etc.)

Automation and control level

Packaging and shipping to the UAE

To get an accurate quote, please share your profile drawing, material specs, and desired machine features. You can send all details to [email protected]

All machines are custom-built and shipped directly to your preferred UAE location — including Abu Dhabi, Dubai, and Sharjah — by our verified global manufacturing partners. Machine Matcher provides full support from quotation to delivery, installation, and after-sales service.

Q1: What is the advantage of the 2” composite deck profile in construction?

A1: The 2" profile offers increased load capacity, better concrete adhesion due to embossments, and acts as permanent formwork, reducing installation time and scaffolding needs.

Q2: Can the machine be customized for different deck profiles?

A2: Yes. The forming stations and tooling can be customized for any composite or metal deck profile based on your drawing and technical requirements.

Q3: What is the delivery time to the UAE?

A3: Standard delivery time is 60–90 days depending on customization and factory workload. Expedited production may be available.

Q4: Does the machine come with installation support in the UAE?

A4: Yes. We offer on-site installation and operator training, along with remote technical support and spare parts supply.

Q5: What maintenance is required for this machine?

A5: Routine maintenance includes roller lubrication, chain/oil inspection, electrical cabinet cleaning, and hydraulic oil level checks. Full documentation is provided with every unit.

Q6: Can I run the machine on UAE power standards?

A6: Absolutely. All systems are configured for 380V, 50Hz, 3-phase, matching UAE industrial standards.

To get a quote or request machine customization:

Email: [email protected]

All machines are new and built to your exact profile and material requirements.

Delivered to Abu Dhabi, Dubai, Sharjah, and all UAE regions with 1-year warranty and full support.

Copyright 2026 © Machine Matcher.