To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

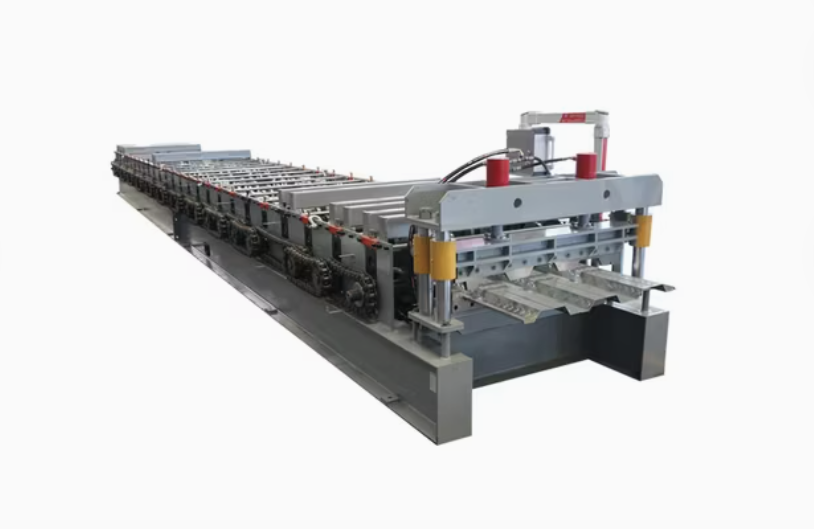

2" Composite Floor Deck Roll Forming Machine – UAE Edition

For High-Strength Composite Deck Production in the Middle East Construction Industry

The 2” Composite Floor Deck Roll Forming Machine is a high-performance, precision-engineered production line designed for manufacturing composite metal decking sheets used in multi-story concrete floor systems. With robust structural capabilities, fast production speed, and user-friendly automation, this roll forming machine is built to serve the booming construction and infrastructure sectors across the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and beyond.

This machine is tailored for UAE's demanding climate and project standards, supporting a wide range of galvanized steel materials with high yield strength, ensuring durability and compliance with international building codes. It is suitable for continuous, heavy-duty production in high-rise commercial, residential, and industrial projects.

Machine Type: 2" Composite Floor Deck Roll Forming Machine

Production Speed: 10–20 meters/minute (adjustable based on material and profile complexity)

Material Thickness Range: 0.75–1.2 mm

Material Width Range: 1000–1300 mm (based on profile shape and coverage)

Material Types: Galvanized Steel (GI), Galvalume, Pre-painted Steel

Material Yield Strength: Up to 550 MPa (suitable for structural-grade decking)

Roller Material: GCr15 (hardened, high chrome alloy steel)

Roller Surface Treatment: Hard chrome-plated (wear-resistant and corrosion-resistant)

Number of Forming Stations: 22–26 stations (customizable for exact profile)

Roller Shaft Diameter: 75 mm

Shaft Material: Solid 45# steel, precision-ground and heat-treated

Main Drive Type: Gearbox chain drive or direct drive (as per order)

Power (UAE standard): 380V / 50Hz / 3Phase

Motor Power: 15 kW – 22 kW (depending on profile and drive type)

Cutting Method: Hydraulic cutting (post-cut system for clean edge)

Blade Material: Cr12MoV, heat-treated and precision ground

Control Type: PLC control system with HMI touch screen (Siemens or Delta)

Operating Mode: Fully automatic with manual override

De-coiling System: Manual or hydraulic uncoiler (3–5 tons capacity)

Punching/Notching System: Optional inline hydraulic notching available

Machine Frame: Heavy-duty H-beam steel base frame

Thickness of Frame Steel: 18–22 mm

Profile Shape: 2" Composite Floor Deck (with embossments for concrete bonding)

Profile Width and Depth: Covering width approx. 960–1020 mm | Rib height: 51 mm (2”)

Length Tolerance: ±2 mm per 6 meters

Protective steel covers/guards over all rotating and moving parts

Emergency stop button installed at key locations

Electrical and hydraulic overload protection system

Optional: light curtain sensor or safety fencing available

This machine is designed for companies engaged in:

High-rise construction

Bridge and highway decking

Industrial warehouses

Steel structure buildings

Large-scale residential developments

Composite floor decks produced by this machine are often used as permanent formwork and reinforcement for concrete floors, making it a critical element in modern urban development projects across the UAE.

Prices Start From: USD $85,000 (FOB basis, standard configuration)

What Affects the Final Price:

Profile customization

Inclusion of hydraulic notching units

Choice of PLC brand (Siemens, Delta, Mitsubishi)

Decoiler automation

Material width and thickness capacity

Speed and drive system upgrades

Installation, training, and warranty extensions

Contact Machine Matcher for a tailored quote based on your project requirements and profile drawings.

All machines are new, custom-built, and include:

One-year warranty from dispatch

Remote and on-site maintenance and repair support

Delivery anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah

Have profile drawings or specifications?

Email them to: [email protected]

Let our team help you match the exact machine to your project.

Q1: What materials can I run through this machine?

A: This machine is optimized for galvanized steel and galvalume with a thickness of 0.75 to 1.2 mm and a yield strength up to 550 MPa.

Q2: Can I produce different deck sizes on the same machine?

A: The machine is built for a specific 2" composite deck profile, but width or rib spacing can be adjusted with optional tooling or cassette systems.

Q3: How long does it take to deliver to the UAE?

A: Average production and delivery time is 60–90 days, depending on customization and factory workload.

Q4: Is installation support available in the UAE?

A: Yes, we offer both remote commissioning and on-site installation and training.

Q5: Can I include notching or embossing features?

A: Yes, embossing is included in most composite deck profiles, and inline notching is available as an optional upgrade.

Q6: What type of uncoiler comes with this machine?

A: A manual uncoiler is included in the standard package; hydraulic decoilers (3–5 tons) are available upon request.

For a fast quote or to learn more about our custom deck machine packages, contact the Machine Matcher team. We’re ready to help you build faster and stronger with precision roll forming systems tailored for the UAE market.

Copyright 2026 © Machine Matcher.