To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

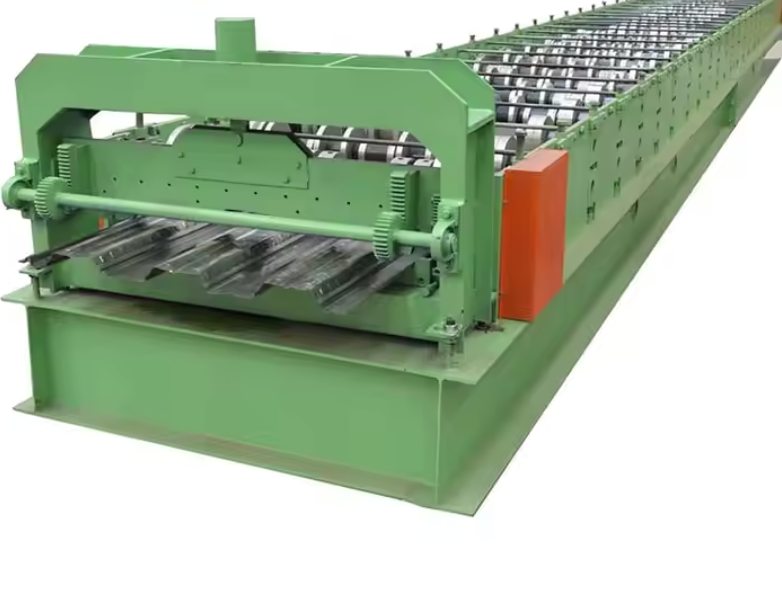

2W Deck Roll Forming Machine – UAE Market Overview

High-Performance Floor Decking Production for Structural Applications

The 2W Deck Roll Forming Machine is a high-efficiency, precision-engineered solution for producing 2W steel floor deck profiles used in multi-story commercial, residential, and industrial buildings across the UAE. Designed to deliver consistent quality under demanding conditions, this machine is ideal for fabricators and construction contractors seeking high-volume production of composite steel decking.

Known for its wide flute spacing and moderate profile depth, the 2W deck profile provides excellent load distribution while allowing optimal concrete bonding in composite floor systems. The machine is custom-built to handle the full range of material thicknesses and widths typically required in the UAE’s construction sector, ensuring flexibility and performance in every run.

Whether you're setting up a new floor decking line or upgrading an existing facility, the 2W Deck Roll Forming Machine is built for durability, speed, and precision — all while meeting regional power standards and production expectations.

The 2W deck profile is widely used in:

Commercial building construction (shopping malls, high-rise buildings, hotels)

Residential towers and complexes

Infrastructure development projects

Industrial and warehouse facilities

Prefabricated and modular building systems

This machine is especially suited for:

Steel fabrication companies

Metal deck profile suppliers

Construction firms involved in structural framing

| Specification | Details |

|---|---|

| Machine Type | 2W Deck Roll Forming Machine |

| Production Speed | 12 – 18 meters per minute (standard) |

| Material Thickness Range | 0.8mm – 1.5mm |

| Material Width Range | 1000mm – 1250mm |

| Material Types | Galvanized steel, Galvalume, Cold-rolled steel |

| Material Yield Strength | Up to 550 MPa |

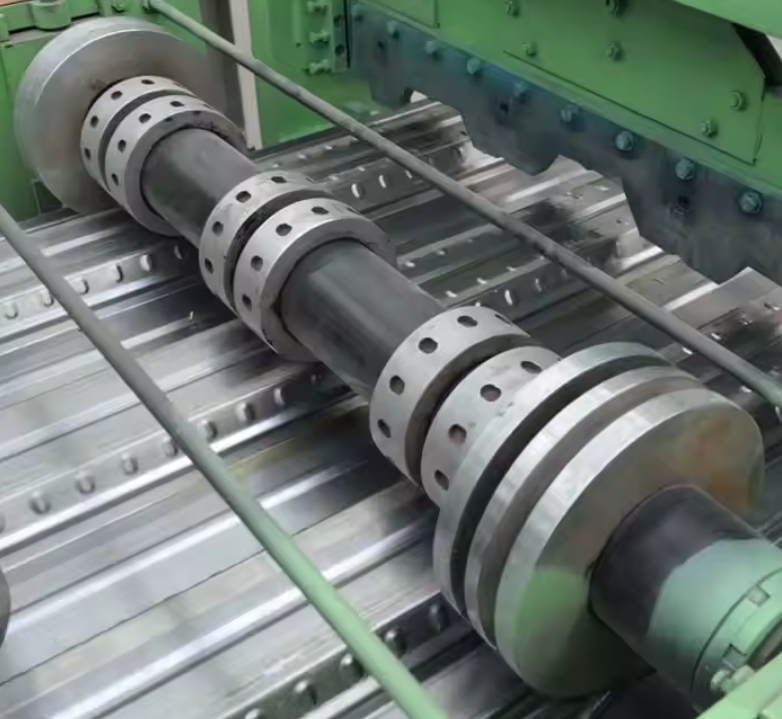

| Roller Material | GCr15 (high-grade forged steel) |

| Roller Surface Treatment | Hard chrome-plated for anti-rust and wear resistance |

| Number of Forming Stations | 24–30 stations (depending on profile length and detail) |

| Roller Shaft Diameter | 80mm |

| Shaft Material | High-grade 45# steel, precision-ground |

| Main Drive Type | Gearbox or Chain Drive (as per customization) |

| Power (UAE Region) | 380V / 50Hz / 3 Phase |

| Motor Power | 22 kW (standard) |

| Cutting Method | Hydraulic post-cut system |

| Blade Material | Cr12MoV (heat-treated, long-life cutting) |

| Control Type | PLC control with HMI touchscreen interface |

| Operating Mode | Automatic and Manual modes |

| De-coiling System | Hydraulic or manual uncoiler, 5–10 Ton capacity |

| Punching/Notching System | Optional hydraulic pre-punching system |

| Machine Frame | Heavy-duty welded steel frame |

| Thickness of Frame Steel | 20mm–30mm |

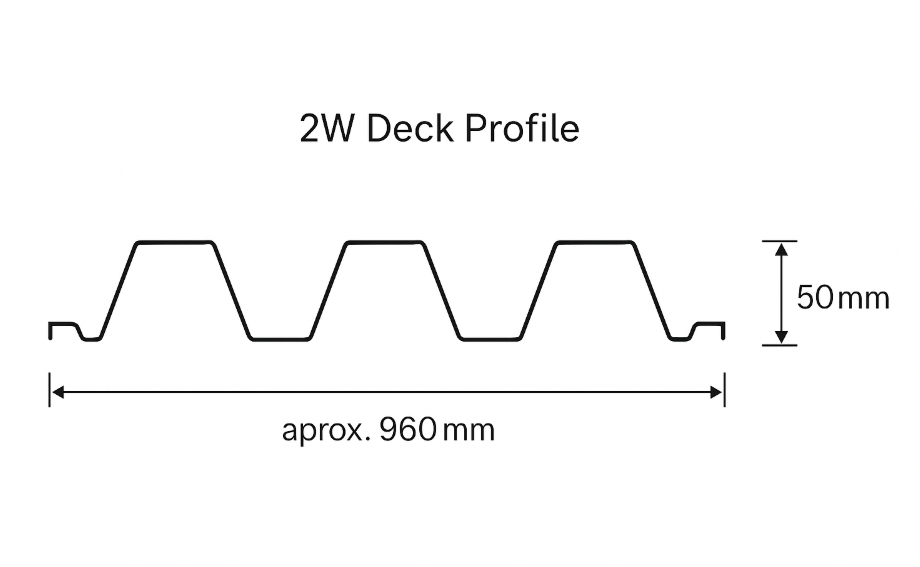

| Profile Shape | 2W trapezoidal deck profile |

| Profile Width and Depth | Effective width ~960mm; Depth ~50mm (adjustable) |

| Length Tolerance | ±2.0mm per 6m |

| Safety Features | |

| - Protective Covers/Guards | Included |

| - Emergency Stop Button | Included |

| - Overload Protection System | Included |

All machines are new and custom-built to meet each customer’s exact profile and technical requirements.

Machine Matcher can deliver this machine anywhere in the United Arab Emirates, including:

Abu Dhabi

Dubai

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Umm Al Quwain

Local voltage and power compatibility are ensured for UAE industrial standards.

Prices start from: USD $65,000 (standard configurations)

What affects the final price:

Type of de-coiler and punching systems

Machine speed upgrades

Servo feeding systems

Advanced PLC brand (e.g., Siemens, Mitsubishi)

Extra safety features and automation packages

Shipping, installation, and training support

Pricing is determined based on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

Q1: What is the difference between 2W and 3W deck profiles?

A: 2W profiles have wider ribs and fewer webs than 3W profiles, making them suitable for medium-span composite slabs and concrete bonding. 3W decks are used where deeper concrete slabs or longer spans are required.

Q2: Is this machine suitable for galvanized steel coil?

A: Yes. The machine is designed to form galvanized and galvalume steel with yield strength up to 550 MPa.

Q3: Can I produce multiple deck profiles on the same machine?

A: With optional quick-change tooling or cassette systems, yes. However, it’s most efficient to dedicate one machine per profile for high-volume production.

Q4: How long does it take to manufacture and deliver this machine to the UAE?

A: Production time is usually 60–75 days from order confirmation. Delivery to UAE ports takes approximately 25–35 days, depending on shipping schedules.

Q5: Is on-site installation and training available in the UAE?

A: Yes. Machine Matcher provides local setup, commissioning, and operator training as an additional service package.

Q6: What kind of maintenance is required for this machine?

A: Regular lubrication, roller cleaning, and alignment checks are essential. The control panel and hydraulic systems should also be inspected periodically to ensure reliable performance.

The 2W Deck Roll Forming Machine is a high-value solution for the UAE’s growing demand for composite decking systems in modern construction. Built for strength, speed, and customization, it is a reliable choice for fabricators and contractors across Dubai, Abu Dhabi, Sharjah, and beyond.

Contact Machine Matcher today to receive a quote, profile consultation, and expert guidance on setting up your next decking line.

Copyright 2026 © Machine Matcher.