To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

The Used ADH Cut Line Shearing 6MM6000 is a robust and reliable industrial shear designed for high-performance metal cutting in demanding fabrication environments. Engineered to handle large sheet sizes and thicker materials, this machine is ideal for manufacturers looking for accuracy, durability, and efficiency in their production processes.

Backed by the trusted reputation of ADH, a leading brand in metalworking machinery, this used model offers a compelling blend of cutting capacity, safety, and precision. With a cutting thickness of up to 6 millimeters and a generous cutting length of 6000 millimeters (6 meters), it is well-suited for a wide range of metal fabrication tasks, including structural steelwork, industrial manufacturing, construction components, and more.

Located in China and ready for international shipping, the ADH Cut Line Shearing 6MM6000 is an excellent opportunity for manufacturers who need large-scale shearing capabilities without compromising on performance or precision.

Thickness: Capable of shearing metal sheets up to 6mm thick, this machine is suitable for heavy-duty materials like carbon steel, stainless steel, and aluminum.

Cutting Length: With a maximum cutting length of 6000mm, it is optimized for full-length sheets and plates, eliminating the need for multiple passes or additional cutting operations.

This large format allows for greater flexibility in production planning and reduces material handling time, which can significantly boost throughput in busy fabrication shops.

The ADH Cut Line series employs high-precision shearing systems that utilize hardened blades and advanced mechanics to ensure smooth, straight cuts every time. The mechanical or hydraulic actuation (based on configuration) delivers consistent power throughout the stroke, reducing wear and increasing blade life.

Key features may include:

Blade gap adjustment for optimal results across different material thicknesses

Backgauge systems for accurate positioning

Adjustable cutting angle to reduce deformation, especially in thicker sheets

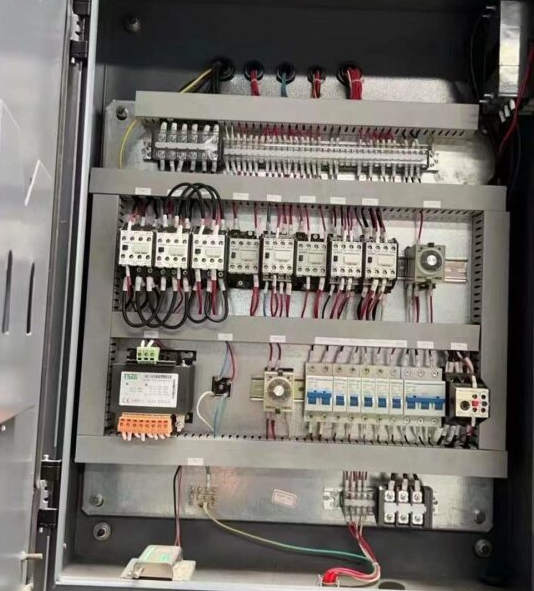

While specific control configurations vary by unit, most ADH shearing machines in this class come with modern control panels or PLC-based systems that allow operators to adjust key parameters such as:

Cutting speed

Stroke frequency

Blade clearance

Cutting length positioning

These settings enable operators to optimize the machine for different material types and production requirements, ensuring repeatability and accuracy across jobs.

This shearing machine is not limited to a single material type. It is capable of cutting:

Mild Steel

Stainless Steel

Aluminum

Galvanized Steel

Brass and Copper (depending on hardness and thickness)

Such versatility makes it a valuable asset in any fabrication workshop that handles varying material types on a regular basis.

ADH machines are built with operator safety as a top priority. Typical safety features include:

Front and rear safety guards to prevent accidental access to moving parts

Emergency stop buttons placed strategically for quick intervention

Hydraulic overload protection

Foot pedal operation with interlock

CE-certified systems (depending on export market and retrofitted components)

These safety features not only protect operators but also reduce the risk of workplace incidents, making the work environment more compliant with international safety standards.

Thanks to its 6-meter cutting length and rapid shearing action, this machine is ideal for operations where time is of the essence. It is built to deliver:

High shearing speeds

Minimal cycle time

Reduced maintenance downtime

Long blade life

Whether in batch production or continuous operation, the ADH Cut Line Shearing 6MM6000 enhances overall shop productivity by minimizing manual labor and increasing process automation.

This is a used unit, offering a cost-effective solution without compromising on industrial-level performance. Buyers are encouraged to request further details regarding:

Blade condition

Hydraulic/pneumatic system performance

Control system configuration

Machine hours

Available accessories or modifications

To ensure that the machine meets your production needs, our team can arrange detailed inspections, additional photos, or video demonstrations upon request.

The machine is currently located in China and is available for immediate export.

Air Freight Delivery: Estimated transit time 7–10 days

Sea Freight Delivery: Estimated transit time 30–45 days (depending on destination)

Our logistics team can handle shipping arrangements and customs documentation to ensure smooth delivery to your location. Whether you're based in Europe, North America, Africa, or Asia, we can coordinate end-to-end delivery solutions.

This shearing machine is widely used in industries such as:

Metal Fabrication Workshops

Construction and Infrastructure

Shipbuilding

Heavy Equipment Manufacturing

Steel Service Centers

Automotive and Rail Components

Any business that processes long metal sheets or requires precise shearing of high-thickness materials can benefit from integrating this machine into their production line.

Cost-effective investment in large-format shearing capacity

High cutting accuracy and consistent performance

Heavy-duty construction ensures long-term durability

Readily available for global shipment

Supported by Machine Matcher’s international sourcing network

This shearing machine is suitable for carbon steel, stainless steel, aluminum, galvanized sheets, and more—up to a thickness of 6mm.

Yes, the 6000mm cutting length is designed precisely for that purpose, making it perfect for operations that handle standard or oversized sheet formats.

Most ADH shears in this size range are hydraulically powered, providing consistent force and durability for heavy-duty applications. However, exact configurations should be confirmed before purchase.

Yes. Standard models typically include emergency stops, safety guards, and interlock systems to comply with safety standards.

Absolutely. We encourage buyers to reach out to our team to request additional images, videos, or even third-party inspection services before purchase.

By air freight: 7–10 days

By sea freight: 30–45 days (may vary by country)

Depending on the unit's condition and the seller’s capabilities, some customization or servicing (such as blade sharpening, control panel upgrades, or hydraulic servicing) may be possible. Contact us to discuss your specific requirements.

If you're looking for a high-capacity shearing machine like the ADH Cut Line Shearing 6MM6000, or if you need help finding a different specification, our team is ready to help. We work with a global network of machine sellers and manufacturers to match you with the right equipment.

Contact us today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Let Machine Matcher connect you with the right machine at the right time—anywhere in the world.

Copyright 2026 © Machine Matcher.