To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

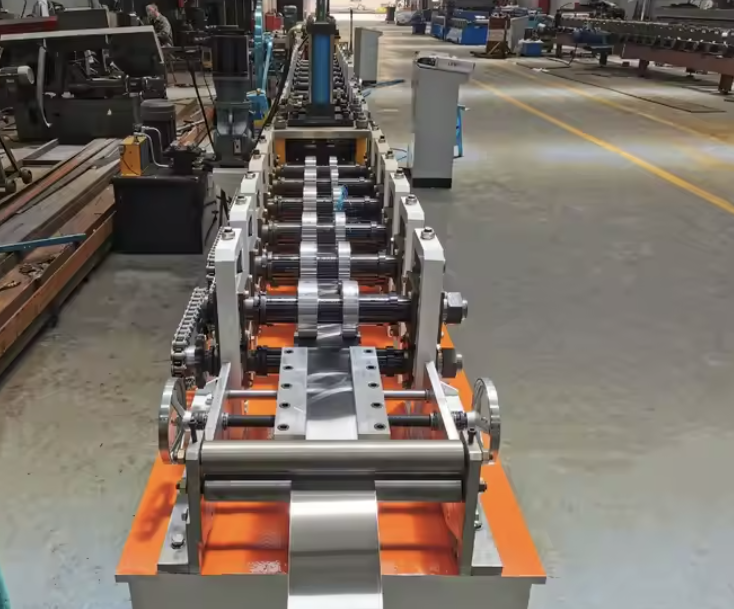

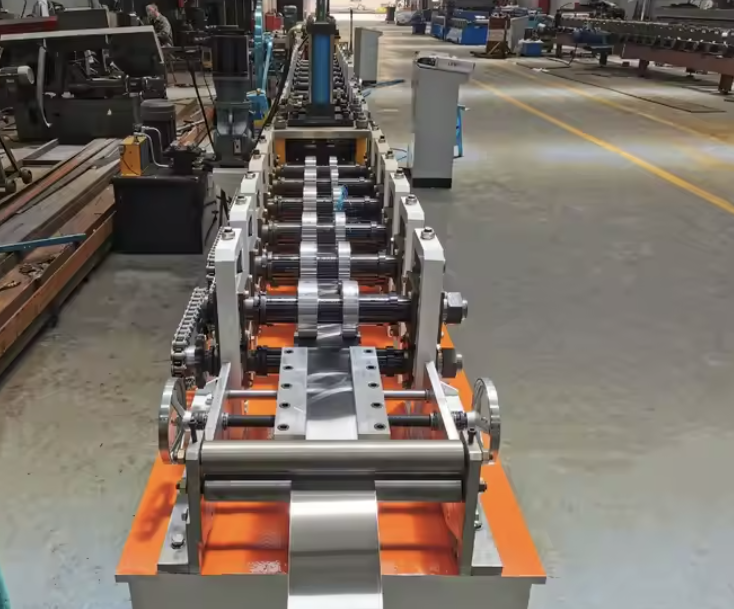

Aluminium Flashing Roll Forming Machine - United Arab Emirates

The Aluminium Flashing Roll Forming Machine is a high-performance industrial equipment designed for producing aluminium flashing profiles with precision and efficiency. Manufactured by Sussman Machinery, this machine ensures reliable performance and durability, making it an ideal investment for businesses in the construction, roofing, and metal fabrication industries in the United Arab Emirates.

The UAE's growing construction and infrastructure sector demands high-quality flashing solutions to ensure durable and weather-resistant building designs. This machine caters to the needs of contractors, manufacturers, and metalworking companies by offering custom-built solutions that meet specific profile and material requirements.

The Aluminium Flashing Roll Forming Machine is widely used in multiple industries across the United Arab Emirates, including:

For a personalized quote, customers can send profile drawings and specifications to [email protected].

Q1: What is the main application of this Aluminium Flashing Roll Forming Machine? A1: This machine is primarily used for manufacturing aluminium flashing for roofing, construction, and metal fabrication industries.

Q2: Can the machine be customized for specific flashing profiles? A2: Yes, we can design the machine according to your specific profile and material requirements.

Q3: What is the power supply requirement for this machine in the UAE? A3: The machine operates on 220V, 60HZ, 3-phase power, which is standard for the UAE industrial sector.

Q4: What is the maximum thickness of the aluminium material the machine can process? A4: The machine is designed to process 0.3mm to 0.8mm thick aluminium and galvanized materials.

Q5: What is the lead time for delivery? A5: Lead time depends on customization and optional extras. Contact us for an estimated delivery timeframe.

Q6: What warranty and support services are available? A6: The machine comes with a 1-year warranty and long-term maintenance and repair support.

Q7: How can I get a quote for this machine? A7: Send your profile drawings, material specifications, and requirements to [email protected] for a detailed quote.

Why Choose Machine Matcher? Machine Matcher is a global leader in roll forming machinery solutions, supplying metal roof panel machines, flashing machines, purlin machines, metal trim machines, slitting lines, metal tile machines, uncoilers, coil cars, embossers, and more. We provide comprehensive machine sales, installation, maintenance, and repair services worldwide.

For more information, contact us today and let us help you find the best roll forming solution for your business!

Copyright 2026 © Machine Matcher.