To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

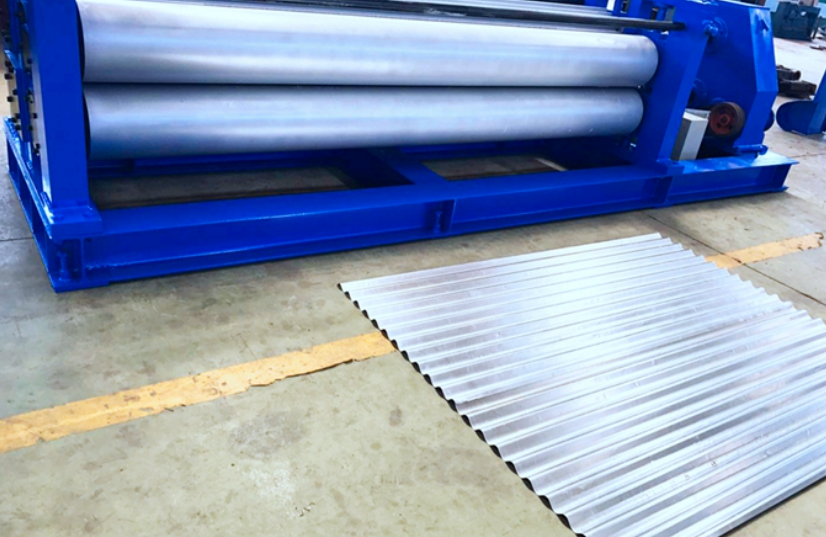

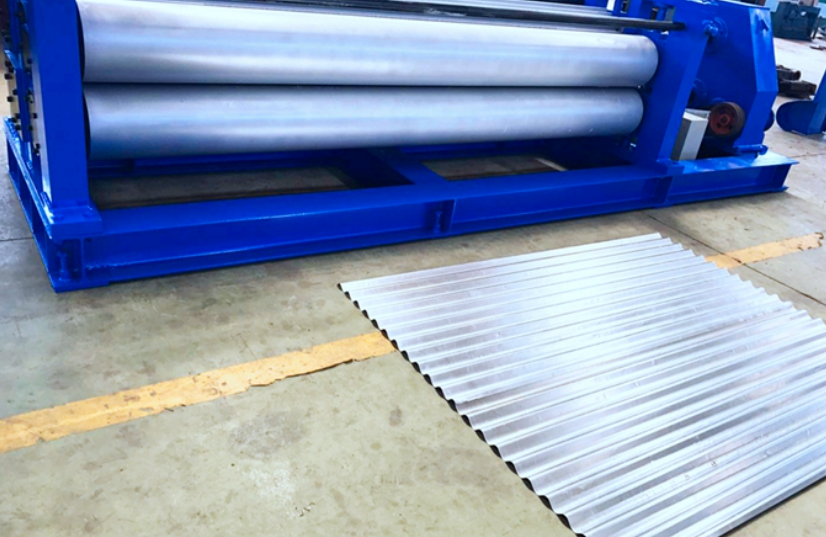

Barrel Corrugated Sheet Machine – United Arab Emirates

Machine Matcher is proud to offer the Barrel Corrugated Sheet Machine to customers across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah. Designed for precision, durability, and high-volume output, this machine is ideal for producing traditional curved corrugated metal sheets used extensively in roofing, cladding, and architectural applications.

This machine is perfect for producing barrel-shaped curved corrugated sheets, commonly used in structures requiring enhanced flexibility and strength — such as agricultural buildings, warehouses, sheds, and even certain roofing systems requiring natural drainage solutions. With adjustable peak distance and height, it offers great versatility for various project requirements.

Profile Flexibility: Adjustable peak height and distance allow customized corrugation shapes.

Heavy-Duty Design: Solid steel frame and durable components for long-term industrial use.

High Production Output: Up to 4.5 tons/hour ensures efficiency in large-scale production.

Customizable Options: Multiple voltage and dimension configurations available.

Fast Delivery in UAE: Shipped and supported directly within the UAE.

The Barrel Corrugated Sheet Machine is widely used in:

Construction & Roofing

Agriculture & Livestock Shelters

Temporary Structures and Warehouses

Prefab Housing & Rural Infrastructure

Cladding Projects in Industrial Zones

Its curved profile is ideal for enhancing water runoff, strength, and wind resistance, making it particularly suitable for Middle Eastern environments.

| Parameter | HH-32C | HH-46C |

|---|---|---|

| Corrugated Iron Thickness | 0.12 mm – 0.6 mm | 0.12 mm – 0.6 mm |

| Max Sheet Length | 3200 mm | 4600 mm |

| Feeding Width | ≤ 1000 mm | ≤ 1000 mm |

| Peak Distance | 75.5 mm (adjustable) | 75.5 mm (adjustable) |

| Peak Height | 16 mm (adjustable) | 16 mm (adjustable) |

| Effective Width | 830 mm (adjustable) | 830 mm (adjustable) |

| Voltage | 380V, 3Phase-50Hz (customizable) | 380V, 3Phase-50Hz (customizable) |

| Power | Approx. 7.5 KW | Approx. 11 KW |

| Feed-in Mode | Manual | Manual |

| Transmission Mode | Separate Drive | Separate Drive |

| Production Capacity | Approx. 3.0 tons/hour | Approx. 4.5 tons/hour |

| Overall Dimensions | 4.9m × 2.0m × 1.4m | 7.2m × 2.2m × 1.6m |

| Gross Weight | Approx. 6300 kg | Approx. 9500 kg |

Prices Start From:

AED 110,000 – AED 170,000 depending on model and optional features.

What Affects the Final Price?

Required sheet length and feeding size

PLC control upgrades

Hydraulic vs manual feeding customization

Local electrical standards (voltage, frequency)

Optional features like auto-stacking or remote monitoring

Freight and delivery in the UAE

Contact Machine Matcher for a custom quote based on your technical requirements.

All machines are new and custom-built to your requirements and come with:

One-year warranty from dispatch

Comprehensive setup guidance

Durable maintenance and technical support

Remote support and optional onsite commissioning (on request)

To ensure the best match for your needs, please send your profile drawings or technical requirements to:

Our team will review your details and provide a fast, accurate quote.

Q1: Can this machine produce curved corrugated sheets for both roofing and cladding?

Yes, it can produce corrugated barrel-shaped sheets suitable for a wide range of architectural and industrial uses.

Q2: What’s the difference between HH-32C and HH-46C?

The HH-46C handles longer sheet lengths (up to 4600 mm) and has a higher capacity (4.5 tons/hour), making it ideal for larger projects.

Q3: Is the voltage suitable for UAE electrical standards?

Yes, the machine is configured for 380V, 3Phase–50Hz, standard in the UAE. Custom voltages can also be requested.

Q4: How long does delivery take in the UAE?

Standard build and delivery lead time ranges from 25 to 45 days depending on customization.

Q5: Is remote operation or automation available?

Yes, we offer automation upgrades including PLC control and motorized decoiling as optional extras.

Q6: What kind of maintenance does this machine require?

Routine lubrication, roller cleaning, and motor inspections are recommended. Full maintenance guidance is provided post-sale.

Local delivery across the UAE

Custom-built solutions for corrugated sheet production

Global expertise with regional support

Reliable after-sales service and technical assistance

Machine Matcher is committed to connecting global buyers with top-tier roll forming equipment and ensuring success in every manufacturing project.

Copyright 2026 © Machine Matcher.