To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

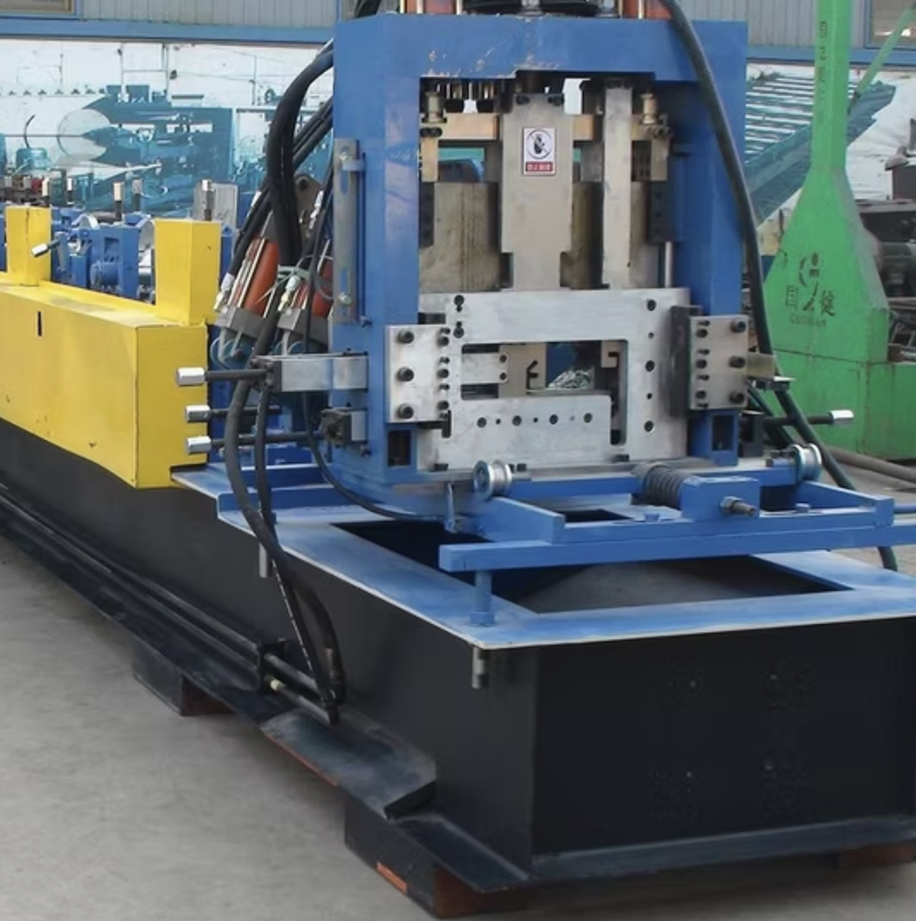

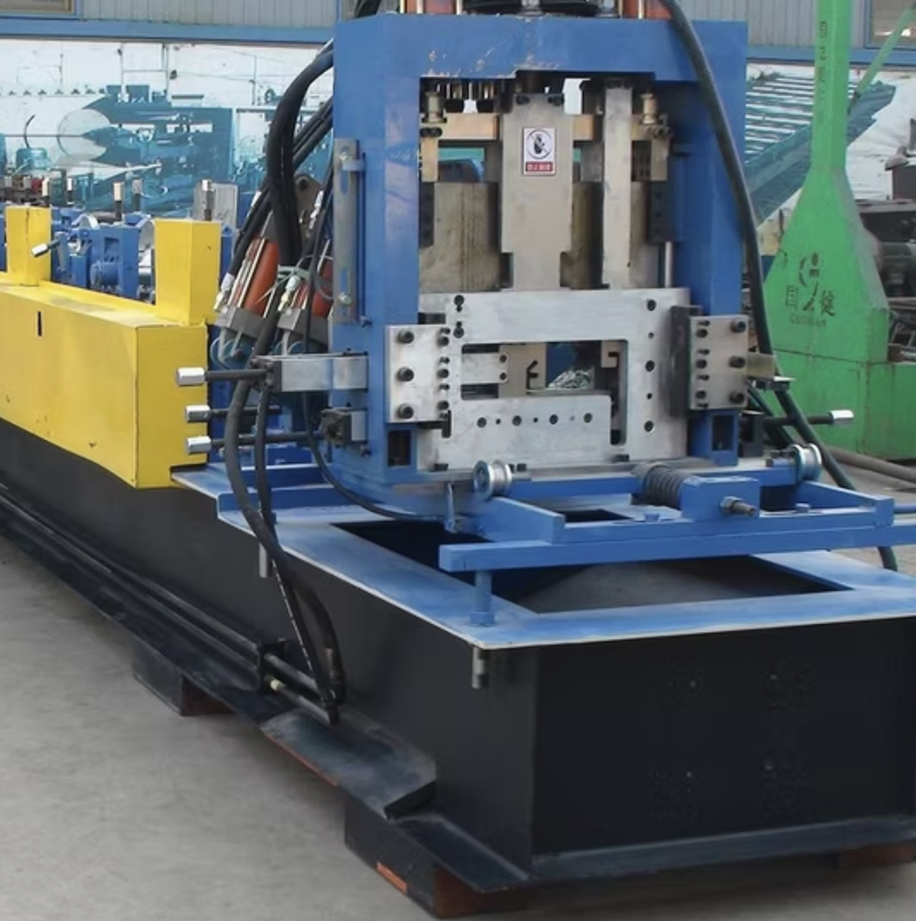

A C channel roll forming machine is a specialized piece of equipment used to produce C-shaped metal profiles commonly used in construction, automotive, and industrial applications. The machine is designed to efficiently form C channels from coil stock, ensuring high precision, consistent quality, and scalability for large-scale production. These channels are widely used in frameworks, support structures, shelving systems, and more.

The C channel roll forming machine comprises several integrated systems that work together seamlessly:

Below are the typical specifications for a standard C channel roll forming machine tailored for the Brazilian market:

| Specification | Details |

|---|---|

| Material Thickness | 1.0mm to 4.0mm |

| Material Width | 100mm to 600mm |

| Material Type | Galvanized steel, stainless steel, aluminum |

| Roller Material | GCr15 steel with chrome coating |

| Machine Speed | 10m/min to 25m/min |

| Cutting System | Hydraulic or Servo motor-driven |

| Punching Options | Hydraulic punching or servo punching |

| Power Supply | 380V, 50Hz (adjustable to Brazilian standards) |

| Control System | PLC with touch screen interface |

| Machine Dimensions | 10m x 1.5m x 1.5m |

| Weight | 8–12 tons (depending on configuration) |

| Additional Features | Safety guards, auto-stackers, remote PLC monitoring |

C channel profiles are integral to various industries in Brazil:

Q1: What is the average production speed of a C channel roll forming machine?

A: The production speed typically ranges from 10m/min to 25m/min, depending on the complexity of the profile and the punching requirements.

Q2: Can the machine handle multiple profile sizes?

A: Yes, with adjustable roller configurations or quick-change cassettes, the machine can produce various profile sizes and shapes.

Q3: Is the machine compatible with Brazilian power supply standards?

A: Absolutely. The machine can be configured to meet Brazilian power standards (380V, 60Hz, or as required).

Q4: What maintenance does a C channel roll forming machine require?

A: Regular maintenance includes lubricating rollers, checking the PLC system, tightening bolts, and cleaning the machine to ensure optimal performance.

Q5: How is shipping and installation managed for customers in Brazil?

A: Machines are shipped in secure crates, and on-site installation and training can be provided by technical experts to ensure smooth operation.

Q6: What industries in Brazil are the largest users of C channel profiles?

A: The construction, automotive, and renewable energy sectors are the major users of C channel profiles in Brazil.

Copyright 2026 © Machine Matcher.