To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

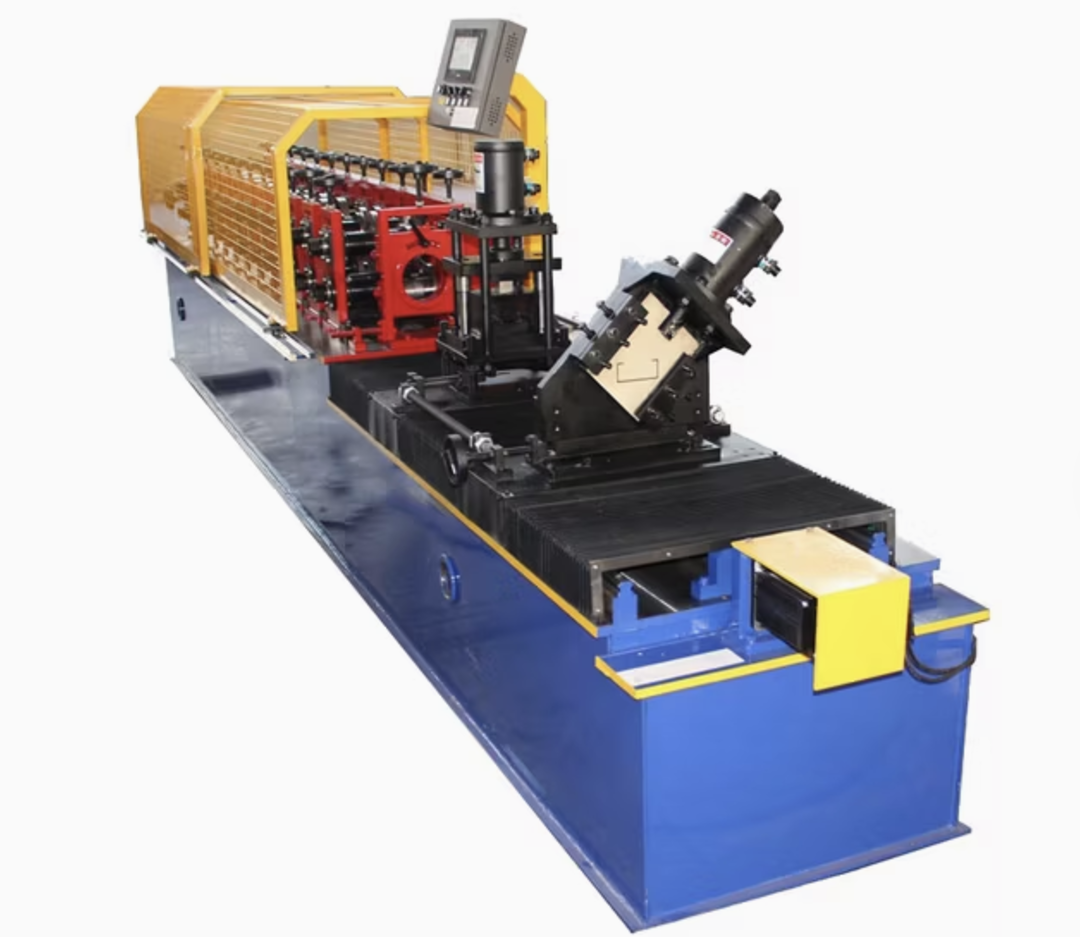

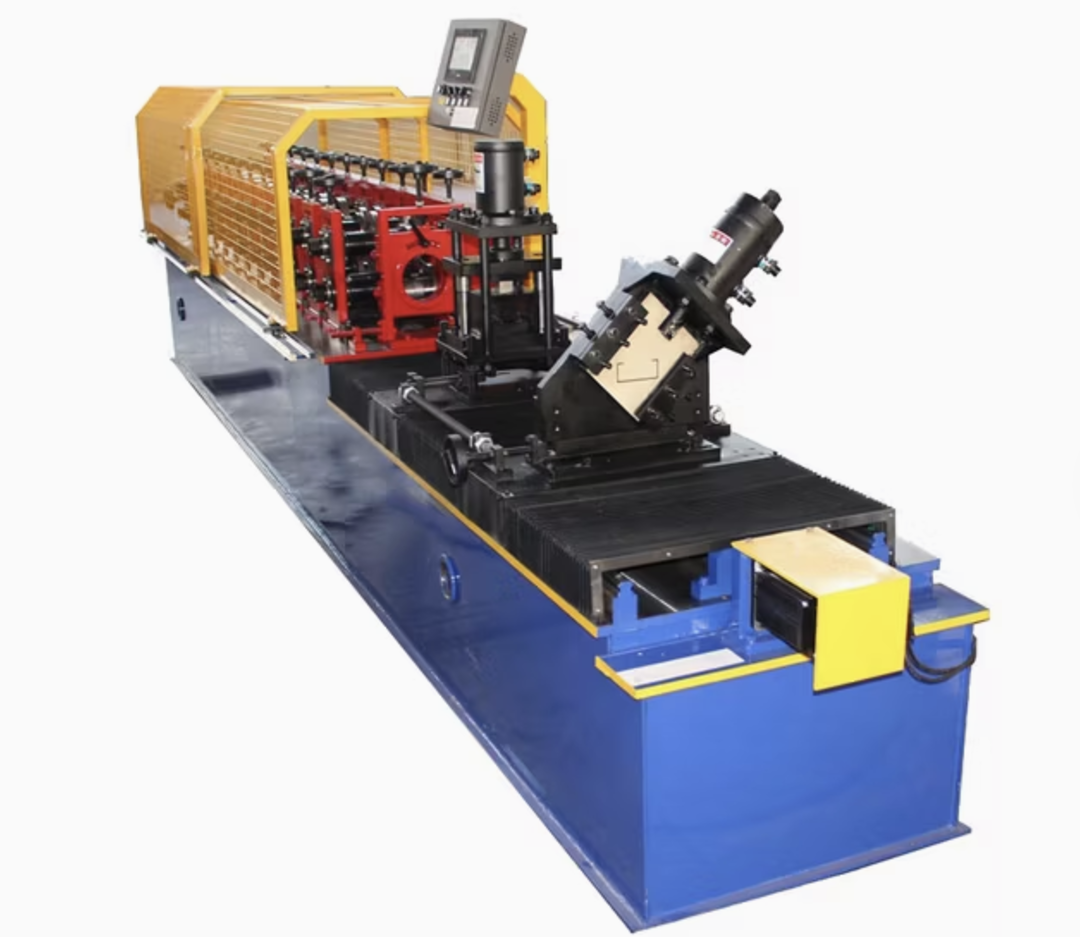

A C Channel Roll Forming Machine is a specialized industrial equipment designed to manufacture C-shaped steel channels commonly used in construction, framing, and structural applications. These machines are essential in Canada’s construction and manufacturing industries, where precise and high-quality steel components are in demand for various projects, including building frameworks, industrial shelving, and infrastructure support.

This guide provides a comprehensive overview of the C channel roll forming machine, including its specifications, features, applications, and answers to frequently asked questions tailored to the Canadian market.

The C Channel Roll Forming Machine is engineered for efficiency, durability, and precision. It transforms metal coils into C-shaped profiles with consistent dimensions and clean edges. The machine operates on a continuous roll forming process, ensuring high productivity and minimal material wastage.

Here are the typical specifications for a C Channel Roll Forming Machine tailored to Canadian industry requirements:

| Component | Specification |

|---|---|

| Material Type | Galvanized steel, stainless steel, aluminum |

| Material Thickness | 0.6 mm - 4.0 mm |

| Material Width | 50 mm - 600 mm |

| Roller Material | GCr15 steel with hard chrome plating |

| Frame Structure | Welded steel frame |

| Motor Power | 7.5 kW - 15 kW (varies with configuration) |

| PLC Control System | Siemens or Mitsubishi (user-friendly interface) |

| Production Speed | 15 m/min to 25 m/min |

| Cutting System | Hydraulic or servo-driven for clean cuts |

| Number of Stations | 12 to 18 forming stations |

| Machine Dimensions | Approximately 8 m x 1.2 m x 1.5 m |

| Voltage Requirements | 220V/380V, 50Hz/60Hz (customizable) |

| Weight | 5 - 8 tons depending on model and configuration |

C channels produced by these machines are widely used across various industries in Canada, including:

The price typically ranges from CAD 60,000 to CAD 120,000, depending on the specifications, automation level, and additional features.

Yes, the machine can be adjusted to produce various sizes and thicknesses of C channels, making it versatile for multiple applications.

Galvanized steel, stainless steel, and mild steel are commonly used. Aluminum can also be processed for lightweight applications.

Yes, the machine can be customized for 220V or 380V, 50Hz or 60Hz, based on Canadian electrical standards.

The initial installation and calibration typically take 1-2 days, depending on the complexity of the setup and site conditions.

Most manufacturers offer a 12-month warranty covering major components like the rollers, motor, and PLC system.

Yes, most suppliers include on-site training or offer remote support to ensure operators can efficiently use the machine.

Regular maintenance of the machine, precise calibration, and using high-quality steel coils are key to achieving consistent quality.

A C Channel Roll Forming Machine is a vital investment for Canadian industries requiring high-quality C channels for diverse applications. With advanced automation, durability, and efficiency, these machines cater to the growing demand for precision-manufactured components in construction and manufacturing sectors. For businesses in Canada, understanding the specifications, features, and maintenance requirements ensures maximum productivity and cost-effectiveness.

Copyright 2026 © Machine Matcher.