To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

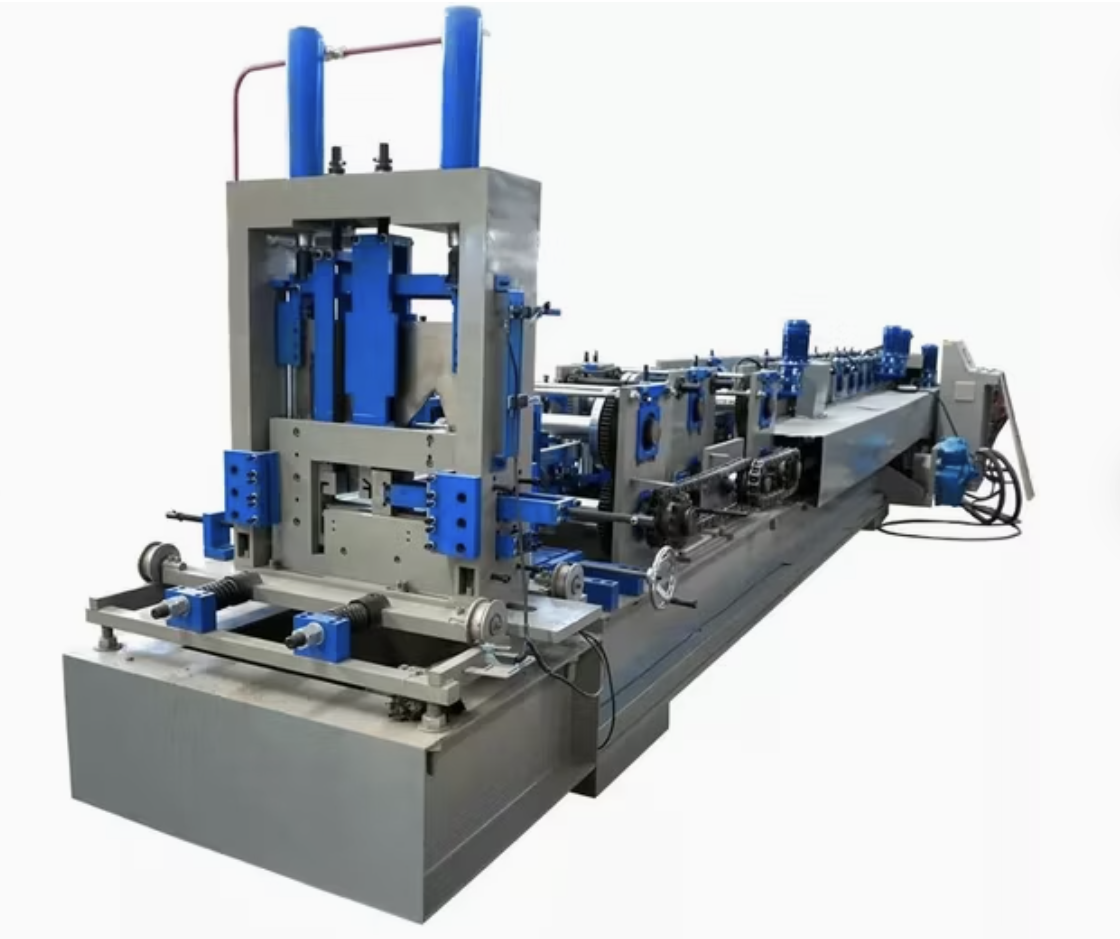

A C Channel Roll Forming Machine is a specialized piece of equipment designed to produce high-quality C-shaped metal channels efficiently. These channels are widely used in construction, infrastructure, and industrial applications due to their structural strength and lightweight properties. The machine transforms metal coils into precisely shaped C channels through a continuous roll forming process, ensuring accuracy, speed, and durability.

This machine caters to industries such as construction (for framing, purlins, and supports), storage solutions (shelving and racks), and transportation (reinforcement in vehicles). With advanced automation and customization options, a C Channel Roll Forming Machine is an essential tool for manufacturers aiming to meet high-volume demands and specific design requirements.

Q1: What industries commonly use C channel roll forming machines?

A1: Industries like construction, automotive, storage solutions, and infrastructure development extensively use C channel roll forming machines to produce structural supports, frames, shelving, and vehicle reinforcements.

Q2: What materials can the machine process?

A2: The machine can handle galvanized steel, mild steel, stainless steel, and aluminum, with thicknesses ranging from 0.8mm to 4.0mm and tensile strengths up to 550 MPa.

Q3: How is the machine controlled?

A3: The machine uses a PLC control system with a touchscreen interface, allowing operators to set parameters such as speed, length, and quantity with ease.

Q4: Can the machine be customized for different profiles?

A4: Yes, the machine can be customized to produce various C channel sizes, flange widths, and hole patterns based on customer requirements.

Q5: Is maintenance required frequently?

A5: Regular maintenance includes lubrication, inspection of rollers and blades, and cleaning the machine. However, high-quality components minimize the frequency of repairs.

Q6: What are the safety features?

A6: Safety features include emergency stop buttons, safety guards, overload protection, and alarms for operational errors.

Q7: Can the machine operate continuously?

A7: Yes, with proper maintenance and a flying cutting system, the machine can operate continuously for high-volume production.

Q8: What are the optional extras available?

A8: Optional extras include:

Q9: What power supply is required?

A9: The machine typically operates on 380V/50Hz but can be customized to match local power requirements.

Q10: How long does it take to install and set up?

A10: Installation and setup usually take 1-2 days, depending on the complexity and customization of the machine.

Copyright 2026 © Machine Matcher.