To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

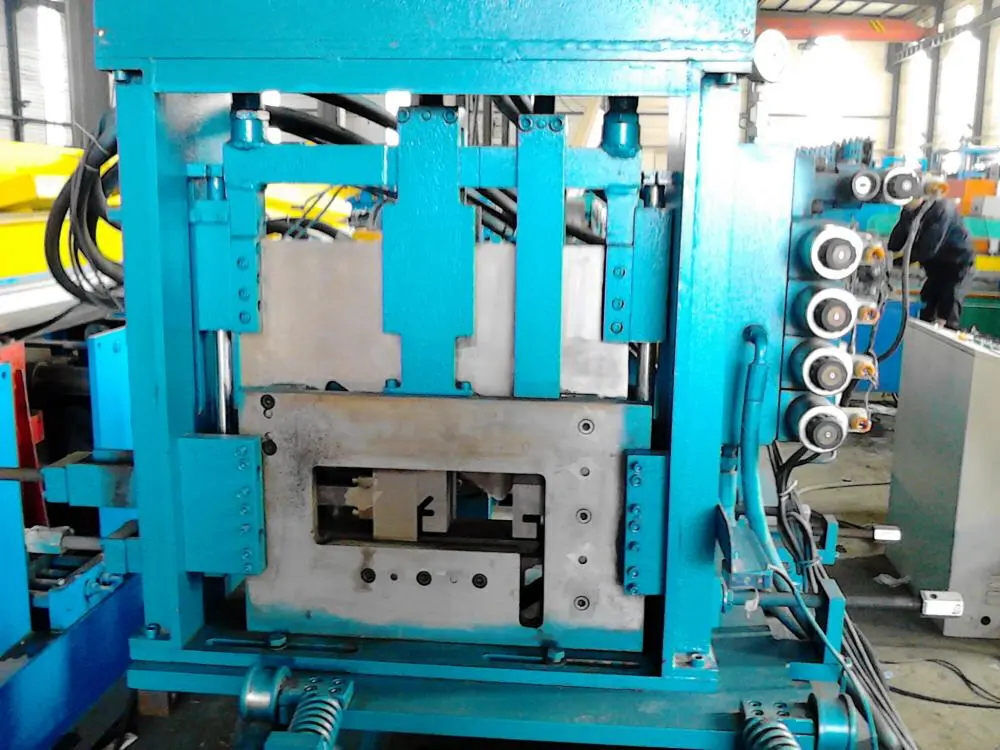

Cable tray roll forming machine uses cantilever type at the two sides, the punch press do the round ribs in bottom or different holes` stamping and cutting. The material is guided into main roll forming machine by guider. By electrical control, automatically improve and adjust different width and height.

Working Flow: Decoiler – Feeding Guide – Servo feeding system – Hydraulic punching – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

| Matching material | Galvanized or PPGI, Aluminum coils |

| Material thickness range | 0.8mm-2.0mm |

| Forming speed | 20-30m/min(excluding punching and cutting time) |

| Hydraulic station power | 22KW |

| Rollers | 20(according to drawings and size) |

| Shaft material and diameter | 80mm, material is 40Cr |

| Material of the body | 400H steel |

| Wall panel | 20mm, Q195 steel(all with electrostatic spraying) |

| Controlling system | PLC |

| Material of rollers | 45# steel with chromed or Cr12(you can choose the material as your request) |

| Material of blade | Cr12 mould steel with quenched treatment 58-62℃ |

| Total weight | About 5 tons |

Copyright 2026 © Machine Matcher.