To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

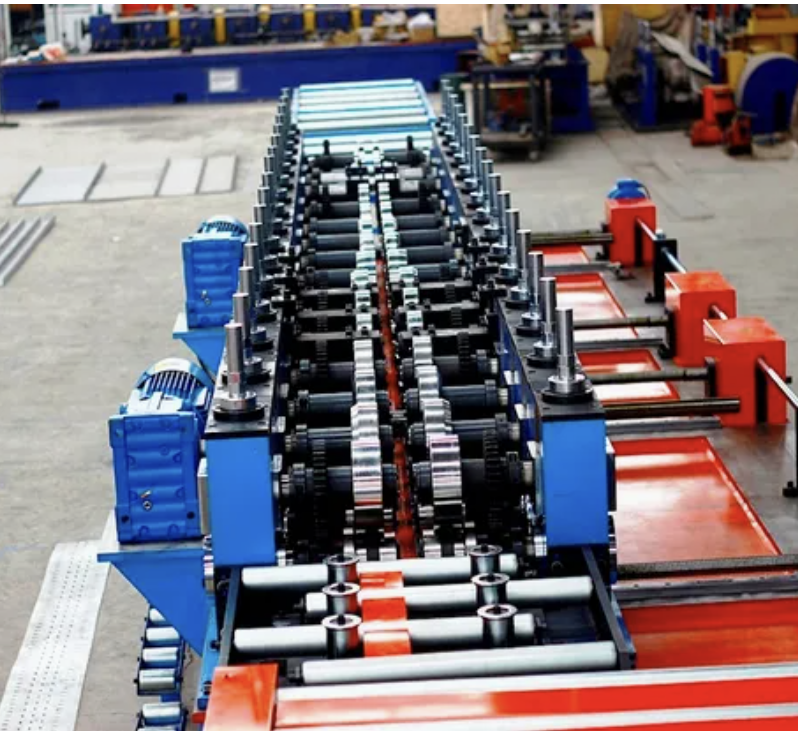

A Cable Tray Roll Forming Machine is a specialized piece of equipment designed to manufacture cable trays, which are essential in electrical installations for housing and supporting cables. This machine automates the production of cable trays in various sizes and profiles, using a continuous roll-forming process. Here's an overview of its specifications and functionality:

The Cable Tray Roll Forming Machine typically includes:

| Parameter | Specification |

|---|---|

| Material Thickness | 0.8mm - 2.0mm (customizable) |

| Material Width | Varies depending on cable tray width (100mm - 600mm) |

| Material Type | Mild steel, galvanized steel, aluminum, stainless steel |

| Forming Speed | 10 - 15 meters per minute (adjustable) |

| Decoiler Capacity | 5 - 7 tons (optional upgrades available) |

| Punching System | Hydraulic or mechanical, with die sets for customization |

| Cutting System | Hydraulic or mechanical, with length adjustment |

| Control System | PLC with touchscreen interface |

| Power Requirement | 380V, 50Hz (or customized based on region) |

| Machine Dimensions | Approx. 11m x 1.5m x 1.5m (varies by design) |

| Machine Weight | Around 10 tons (depends on configuration) |

The Cable Tray Roll Forming Machine is highly adaptable and essential for manufacturers supplying to electrical and construction industries, meeting demand for various tray sizes and configurations.

Copyright 2026 © Machine Matcher.