To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Composite Floor Deck Roll Forming Machine – UAE Market

Delivering High-Strength Floor Decking Solutions for the UAE's Construction Industry

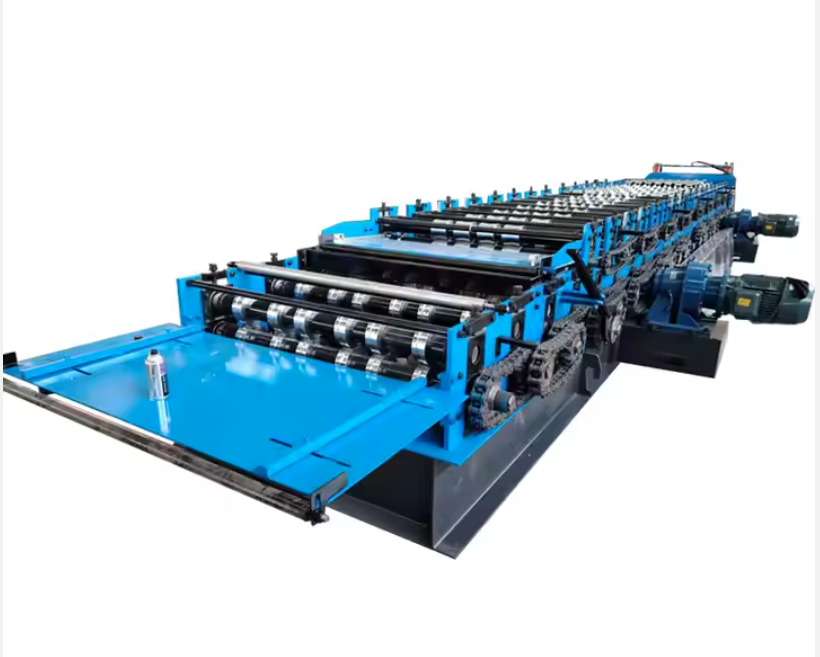

The Composite Floor Deck Roll Forming Machine is a heavy-duty, precision-engineered industrial forming line designed to produce structural floor decking profiles that serve as a permanent formwork in reinforced concrete slabs. Built for high-capacity construction and infrastructure projects in the UAE, this machine produces composite metal floor decking used extensively in commercial buildings, high-rise towers, bridges, and industrial floors.

Equipped with advanced control systems, durable roller materials, and high-speed forming capabilities, the machine is engineered for reliability, strength, and adaptability—qualities demanded by the Gulf region’s fast-paced and large-scale construction environments. Whether you are building a skyscraper in Dubai or an industrial warehouse in Sharjah, this roll forming line delivers consistent deck profiles that enhance concrete bonding, structural stability, and construction speed.

Commercial construction (malls, towers, business parks)

Infrastructure and transportation (bridges, airports, metro stations)

Industrial buildings and logistics centers

Pre-engineered building (PEB) systems

High-rise residential construction

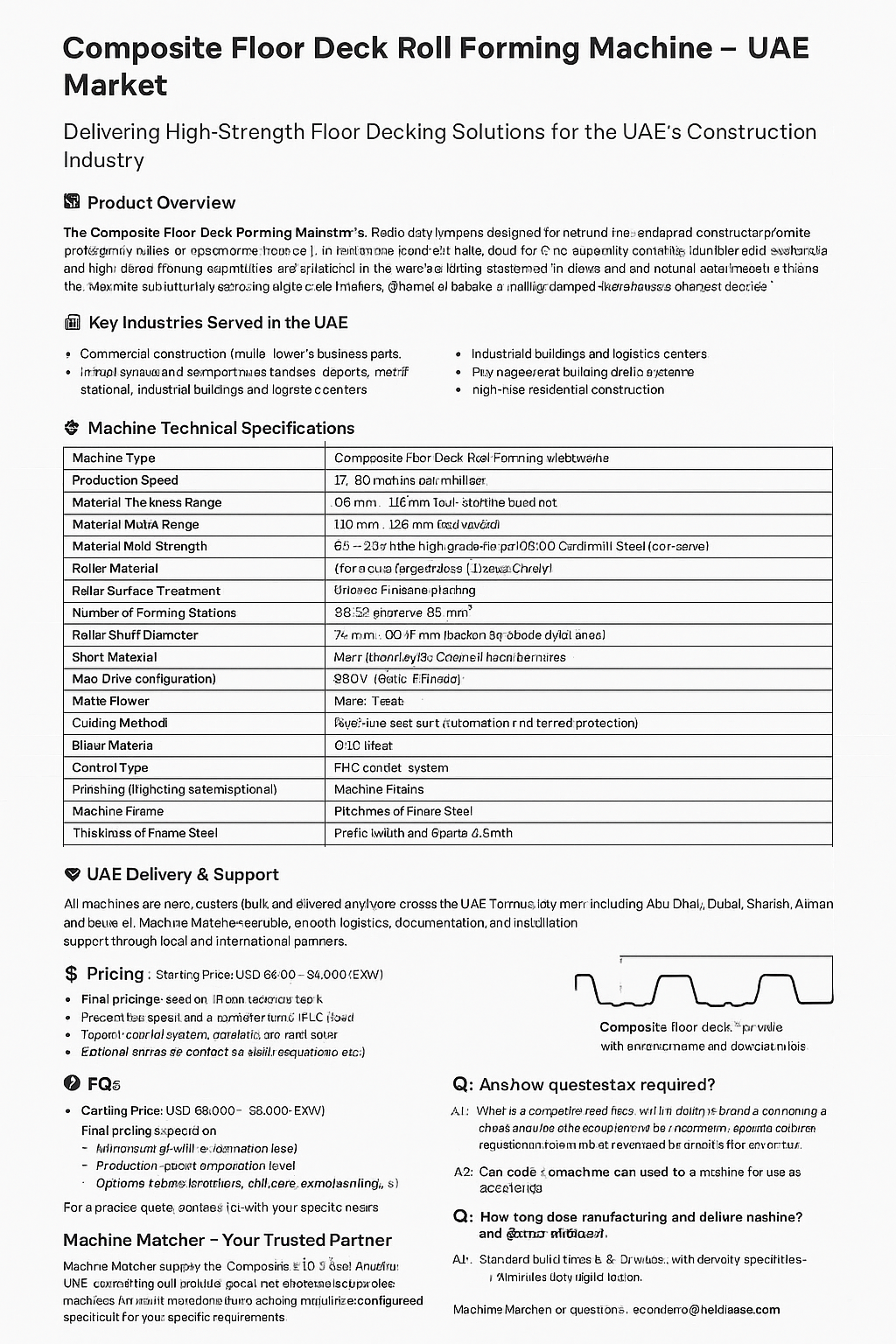

| Specification | Details |

|---|---|

| Machine Type | Composite Floor Deck Roll Forming Machine |

| Production Speed | 12–20 meters per minute (adjustable based on profile complexity) |

| Material Thickness Range | 0.8 mm – 1.5 mm |

| Material Width Range | 1000 mm – 1250 mm (coil width) |

| Material Types | Galvanized Steel (GI), Galvalume, Cold Rolled Steel |

| Material Yield Strength | 250 – 550 MPa |

| Roller Material | High-grade forged steel (GCr15 or Cr12MoV) |

| Roller Surface Treatment | Hard chrome coated (to prevent corrosion and wear) |

| Number of Forming Stations | 24–32 stations (based on profile depth and complexity) |

| Roller Shaft Diameter | 75 mm – 90 mm |

| Shaft Material | High-strength 45# steel, quenched and tempered |

| Main Drive Type | Chain or Gearbox drive (customizable) |

| Power (UAE configuration) | 380V / 50Hz / 3Phase (can be customized for UAE grid systems) |

| Motor Power | 15–22 kW main forming motor + 4 kW hydraulic station |

| Cutting Method | Hydraulic post-cut system (non-stop shearing) |

| Blade Material | Cr12 steel with heat treatment |

| Control Type | PLC control system (Siemens, Mitsubishi, or Delta) |

| Operating Mode | Fully automatic with HMI touchscreen |

| De-coiling System | 5–10 Ton Manual or Hydraulic Uncoiler |

| Punching/Notching System | Optional hydraulic notching or embossing stations |

| Machine Frame | H-Beam steel welded base |

| Thickness of Frame Steel | 18 mm – 25 mm |

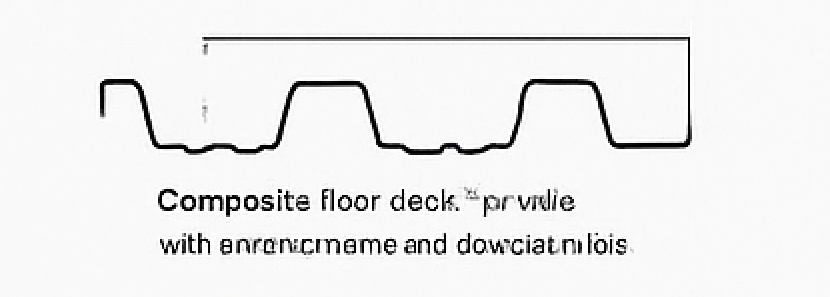

| Profile Shape | Composite deck profile with embossments and dovetail ribs |

| Profile Width and Depth | Effective width: ~600–1000 mm, Depth: 50–76 mm |

| Length Tolerance | ±1.5 mm |

| Safety Features | Fully enclosed guards, e-stop buttons, and overload protection |

| Protective Covers/Guards | Included |

| Emergency Stop Button | Included at multiple stations |

| Overload Protection System | Integrated in electrical and hydraulic systems |

All machines are new, custom-built, and delivered anywhere across the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, Ajman, and beyond. Machine Matcher ensures smooth logistics, documentation, and installation support through local and international partners.

Each machine comes with:

One-year warranty from dispatch

Remote support and commissioning options

Long-term maintenance and spare parts support

To help you get the best price and custom configuration, we recommend sharing any decking profile drawings, size requirements, and application details by emailing us at [email protected].

Starting Price: USD 65,000

Final pricing is based on:

Profile design and depth

Production speed and automation level

Type of control system (PLC brand)

Optional extras (stackers, coil cars, embossing, etc.)

For a precise quote, contact us with your specifications and location requirements.

Q1: What is a composite floor deck and why is it used?

A1: Composite floor decks are steel decking profiles designed to bond with concrete, creating a strong and efficient slab system in buildings. They speed up construction and reduce the need for traditional formwork.

Q2: Can this machine produce multiple deck profiles?

A2: Yes. With interchangeable tooling or adjustable cassettes, it can be configured to produce various composite floor deck profiles depending on your needs.

Q3: What power supply is required for operation in the UAE?

A3: The machine is designed for 380V / 50Hz / 3-Phase power, which is standard across the UAE. Other voltages can be customized.

Q4: Can I order a machine for use in both the UAE and other GCC countries?

A4: Absolutely. Machines can be configured for any GCC country’s standards, and Machine Matcher arranges regional delivery and commissioning.

Q5: What optional systems can be added to this machine?

A5: You can add:

Automatic stackers

Coil car tippers

Hydraulic uncoilers

Embossing/punching stations

Remote PLC diagnostic systems

Q6: How long does it take to manufacture and deliver the machine?

A6: Standard build time is 8–12 weeks, with delivery timelines varying by location and customization.

Machine Matcher proudly supplies this Composite Floor Deck Roll Forming Machine across the UAE, connecting you with trusted global manufacturers and ensuring machines are configured specifically for your application, power supply, and profile requirements.

For quotes, drawings, or questions, contact:

[email protected]

Copyright 2026 © Machine Matcher.