To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Composite Floor System Roll Forming Machine – UAE Market

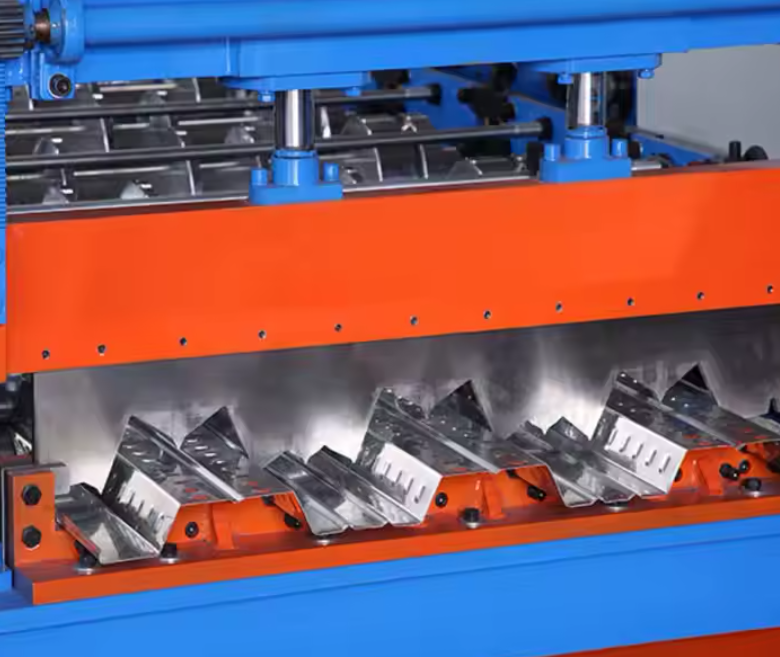

The Composite Floor System Roll Forming Machine is engineered to produce high-strength, steel deck panels used in composite floor slab construction. Designed for robust performance and long-term operation in demanding UAE construction environments, this roll forming machine offers precision forming for composite metal decking used in multi-story buildings, commercial towers, and industrial structures.

The UAE construction sector—particularly in Dubai, Abu Dhabi, and Sharjah—demands advanced flooring systems that integrate concrete and steel for strength, fire resistance, and fast construction cycles. This machine meets that need by forming interlocking steel profiles with embossments or ribbed features, improving the bonding with concrete and ensuring structural integrity.

The Composite Floor System Roll Forming Machine is a heavy-duty, automatic forming solution that converts galvanized or cold-rolled steel coil into precision floor decking profiles. It is optimized for UAE’s high-rise and infrastructure development projects, where speed, accuracy, and reliability are key.

Equipped with a PLC control system, precision-ground rollers, and optional punching or embossing units, the machine allows fast switching between profile lengths and batch runs. Its robust steel frame and advanced drive system ensure durability in hot climates, and all machines are new, custom-built per customer’s specifications and shipped directly to the UAE.

Whether used for commercial towers, industrial plants, or bridge decks, this roll forming machine produces composite floor decking that enhances load distribution and minimizes construction time.

| Specification | Detail |

|---|---|

| Machine Type | Composite Floor System Roll Forming Machine |

| Production Speed | 10–20 meters per minute (adjustable based on profile complexity) |

| Material Thickness Range | 0.8mm – 1.5mm |

| Material Width Range | 1000mm – 1300mm (based on coil input) |

| Material Types | Galvanized steel (GI), Galvalume, Cold-rolled steel |

| Material Yield Strength | Up to 550 MPa |

| Roller Material | GCr15 (high-grade bearing steel) |

| Roller Surface Treatment | Hard chrome plating for corrosion and wear resistance |

| Number of Forming Stations | 20–28 stations (customizable depending on profile) |

| Roller Shaft Diameter | 70mm |

| Shaft Material | High-strength 45# steel, precision ground |

| Main Drive Type | Chain or gearbox drive (optional) |

| Power (UAE-Compatible) | 380V / 50Hz / 3 Phase |

| Motor Power | 15–22 kW (depending on configuration) |

| Cutting Method | Hydraulic post-cut |

| Blade Material | Cr12MoV (heat-treated for durability) |

| Control Type | PLC control (Siemens/Mitsubishi options available) |

| Operating Mode | Fully automatic with touch screen interface |

| De-coiling System | 5–10 Ton manual or hydraulic decoiler |

| Punching/Notching System | Optional embossing or shear punching unit |

| Machine Frame | Welded structure, stress-relieved |

| Thickness of Frame Steel | 20mm side wall panel |

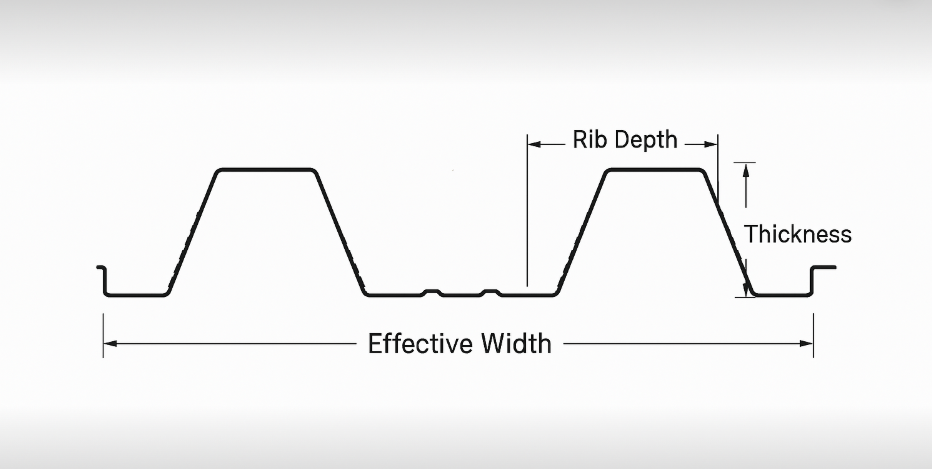

| Profile Shape | Composite floor deck profile with embossments |

| Profile Width and Depth | Effective Width: 600–1000mm; Rib Depth: 50–75mm (customizable) |

| Length Tolerance | ±1.5mm |

| Safety Features | Full cover guards, E-stop system, overload relay |

| Protective Covers/Guards | Included as standard |

| Emergency Stop Button | Yes |

| Overload Protection System | Included for motor and hydraulic system safety |

Starting Price: USD $65,000 (depending on specifications and extras)

Location: Machines are manufactured new and can be delivered across the UAE, including Dubai, Abu Dhabi, Sharjah, Ajman, and beyond.

Required profile shape and size

Coil width and thickness range

Production speed and automation level

Optional features (e.g., embossing, hydraulic decoiler, auto stacker)

PLC brand preference (Siemens, Mitsubishi, Delta)

Local installation or remote commissioning services

Every machine is custom-built to meet specific production goals. Contact us for a tailored quotation.

Construction & Infrastructure: Multi-story buildings, malls, warehouses

Pre-engineered Buildings (PEB): Metal deck floors in steel structures

Bridge Decking Systems: Composite slab with reinforcement

Industrial Facilities: Heavy-load platforms and mezzanine flooring

Commercial Projects: Parking garages, malls, office towers

All machines are new and built to order.

Delivered across the United Arab Emirates including:

Dubai

Abu Dhabi

Sharjah

Ajman

Fujairah

Machines are supported by a 1-year warranty from dispatch and ongoing maintenance and repair services.

To receive an accurate quote, please email:

[email protected]

Include:

Profile drawings or sketch

Material thickness and type

Desired production speed

Required extras (decoiler, stacker, etc.)

Q1: What material types can this machine process?

A: It is designed for galvanized steel, Galvalume, and cold-rolled steel with high yield strength (up to 550 MPa).

Q2: Can the machine be customized for different profiles?

A: Yes, each machine is custom-built according to your required deck shape, depth, and width.

Q3: Is installation provided in the UAE?

A: Yes, installation, remote setup, and operator training services are available upon request.

Q4: How long does delivery take?

A: Typical lead time is 60–90 days from order confirmation, depending on the complexity of the build.

Q5: Can I use this machine for composite slab bridge decks?

A: Yes. It is well-suited for both commercial and infrastructure decking applications including bridges.

Q6: Do you offer financing or installment options?

A: Financing options may be available through local banks or leasing providers. Machine Matcher can assist in connecting you with local partners.

For more details, expert consultation, or a custom quotation:

[email protected]

Machine Matcher – Global Machines. Local Support.

Copyright 2026 © Machine Matcher.