To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

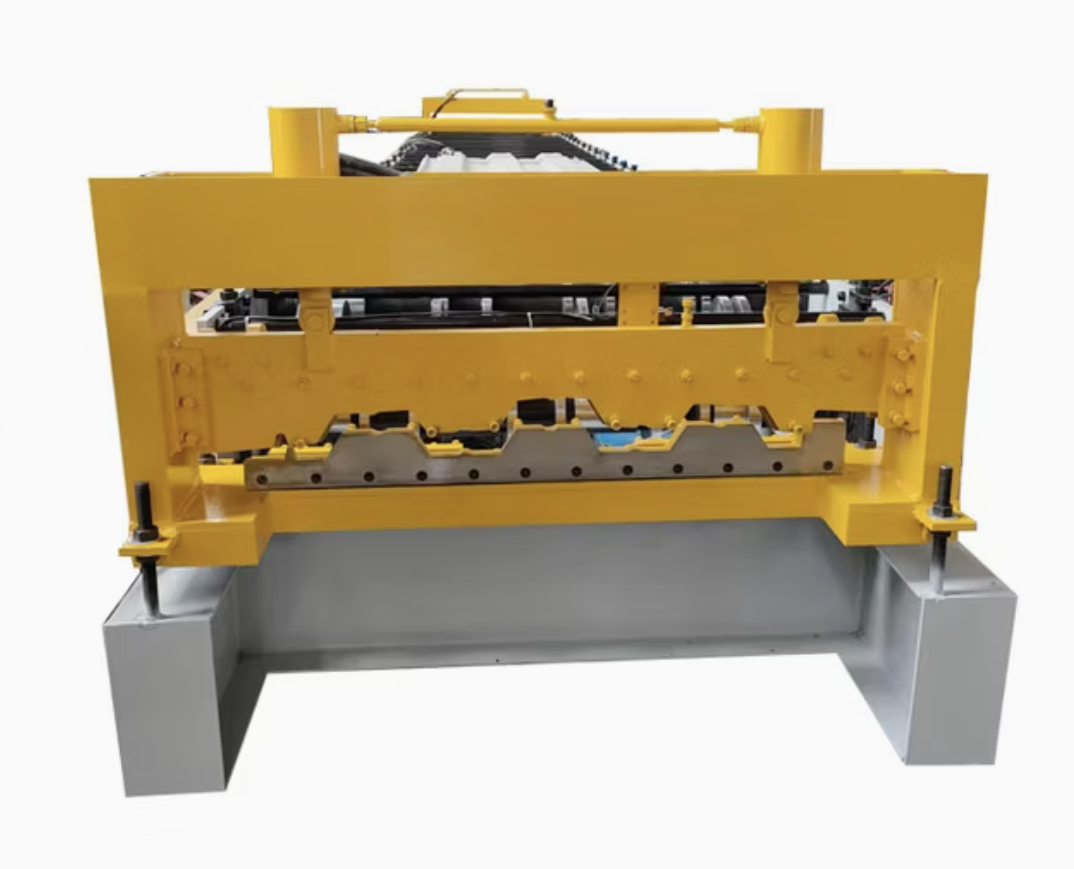

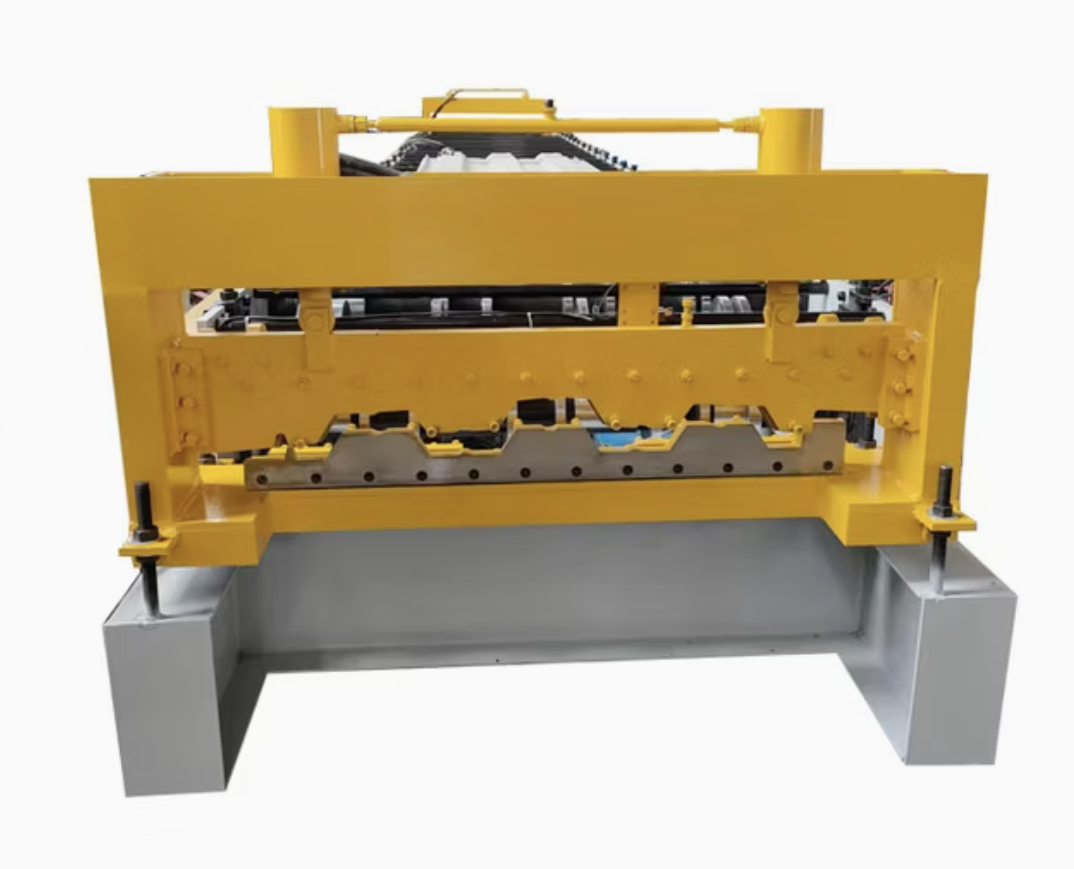

The Composite Metal Deck Roll Forming Machine is designed for precision manufacturing of composite steel floor decking panels, which are essential for commercial, industrial, and residential construction projects across the United Arab Emirates, including Abu Dhabi, Dubai, and Sharjah.

Composite metal decks provide critical structural performance for multi-story buildings by bonding with concrete to create robust composite floors. This roll forming machine is expertly engineered to produce high-quality decking panels efficiently, meeting the growing construction demands of the UAE's dynamic real estate and infrastructure sectors.

Built to the highest international standards, every machine is brand new and custom-built to meet each customer's specific profile requirements and project needs.

We deliver directly from our manufacturing partner to your location in the UAE — whether in Abu Dhabi, Dubai, Sharjah, or any other emirate.

Machine Type: Composite Metal Deck Roll Forming Machine

Production Speed: 10–15 meters per minute (standard); adjustable upon request

Material Thickness Range: 0.8 mm – 1.5 mm

Material Width Range: 800 mm – 1250 mm (depending on profile)

Material Types: Galvanized Steel (GI), Galvalume (AZ), Cold Rolled Steel (CRS)

Material Yield Strength: 250–550 MPa

Roller Material: High-Grade Forged Steel (GCr15)

Roller Surface Treatment: Hard chrome coating for wear resistance

Number of Forming Stations: 24–32 stations (customizable depending on profile)

Roller Shaft Diameter: 90 mm

Shaft Material: 45# high-strength steel, precision machined

Main Drive Type: Chain Drive or Gearbox Drive (optional)

Power: Configured for UAE electrical standards (380V / 50Hz / 3 Phase)

Motor Power: 22 kW (adjustable based on production needs)

Cutting Method: Hydraulic Post-Cutting System

Blade Material: Cr12MoV high-strength alloy steel, heat-treated for durability

Control Type: PLC Computer Control (brands like Siemens, Delta, or Mitsubishi)

Operating Mode: Fully Automatic with Manual Override Option

De-coiling System: Manual or Hydraulic Uncoiler (5-ton or 10-ton optional)

Punching/Notching System: Optional inline punching system available

Machine Frame: Heavy-Duty H-Beam Welded Frame

Thickness of Frame Steel: 20 mm

Profile Shape: Custom Composite Metal Decking Profile (trapezoidal and/or ribbed)

Profile Width and Depth: Typically 600–1000 mm wide, 50–75 mm rib depth (depending on customer specification)

Length Tolerance: ± 2 mm

Safety Features:

Protective Covers/Guards over all moving parts

Emergency Stop Button at multiple locations

Overload Protection System integrated with drive motor

This machine is essential for:

Commercial Building Construction

Industrial Warehouse Construction

Residential High-Rise Projects

Infrastructure Projects (Airports, Metro Stations)

Prefabricated Modular Buildings

Shopping Malls and Retail Centers

Given the UAE's continuous development boom in sectors like hospitality, finance, and real estate, the composite metal deck roll forming machine is a crucial investment for contractors, construction firms, and building material suppliers in the region.

All Composite Metal Deck Roll Forming Machines are:

New and Custom Built to customer profiles

Delivered Anywhere in the UAE including Abu Dhabi, Dubai, Sharjah, and other emirates

Covered by a 1-Year Warranty (from dispatch)

Supported by Durable Maintenance and Repair Services

Note: Pricing depends on optional extras, such as automatic stackers, hydraulic decoilers, or punching systems. Contact us for a customized quotation.

If you have profile drawings or specific requirements, please email them to [email protected] for a detailed and accurate quote.

A1: Yes, the machine can be customized to produce a range of composite deck profiles depending on your project's needs. Multiple tooling setups can also be discussed.

A2: Standard delivery time is 90–120 days depending on complexity. Installation and setup can be completed within 7–10 days after delivery with optional on-site support available.

A3: Yes, we offer remote training and optional on-site training to ensure smooth operation and maintenance for your team.

A4: For thicknesses beyond 1.5 mm, custom machine upgrades are available. Please mention your requirement when contacting us.

A5: Spare parts are readily available. During the warranty, parts are covered unless caused by misuse. After warranty, we continue to supply parts at competitive pricing.

A6: Yes, optional extras like automatic stacking systems, coil car tippers, and upgraded punching units can be added depending on your production goals.

For inquiries, customized quotations, or to send your profile drawings:

Email: [email protected]

We proudly support builders, contractors, and manufacturers across the UAE with high-quality, reliable roll forming equipment.

Copyright 2026 © Machine Matcher.