To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

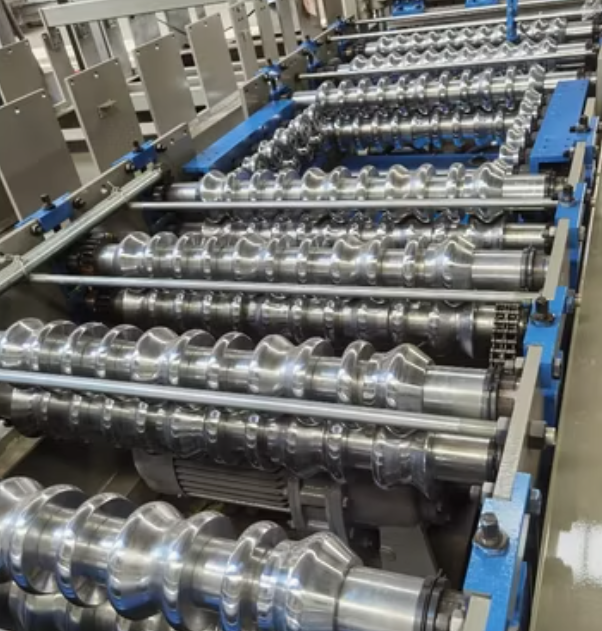

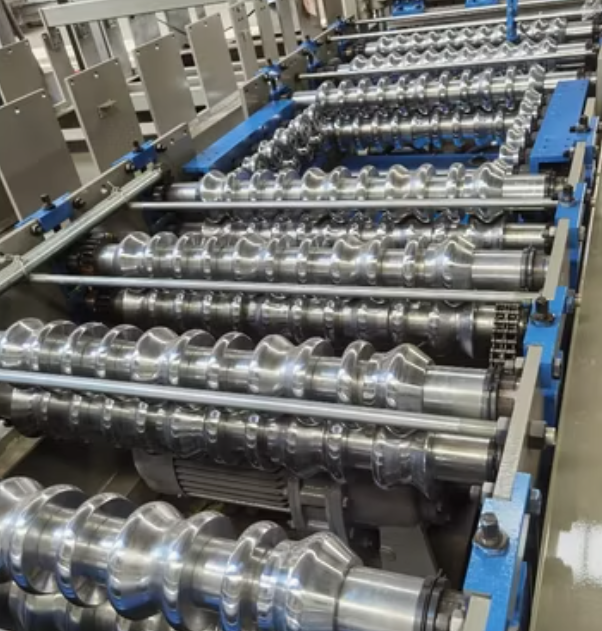

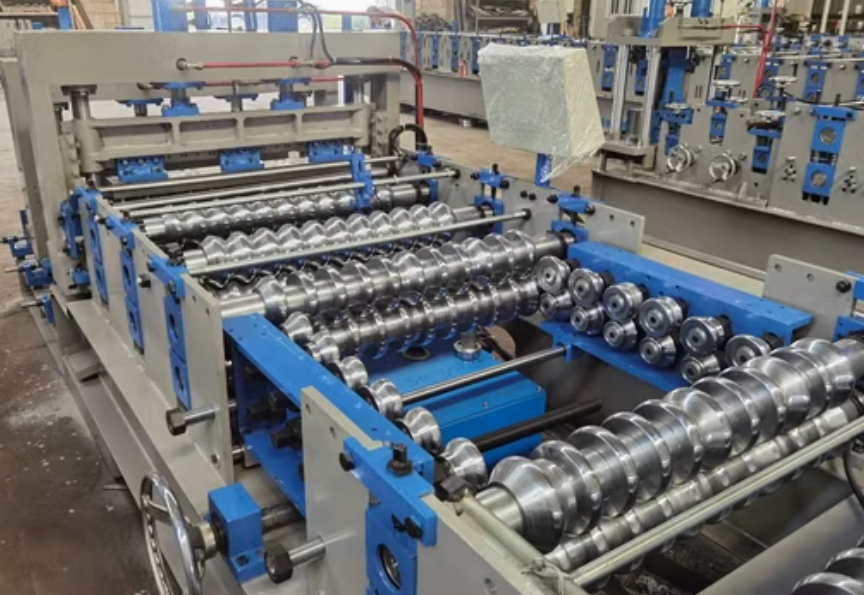

The Corrugated Metal Roofing Roll Forming Machine – Algeria is a robust, high-efficiency production line engineered to form corrugated steel roofing sheets from galvanized, galvalume, or pre-painted coils. These corrugated sheets are a cornerstone of industrial, commercial, agricultural, and residential construction, providing cost-effective and long-lasting roofing solutions.

At Machine Matcher, we design and supply new, custom-built corrugated roof roll forming machines for the Algerian market — tailored to your profile drawing, coil width, and production capacity. Each machine is equipped with PLC control, precision rollers, hydraulic cutting, and automatic length programming, ensuring consistent sheet quality and high production output.

With Algeria’s construction industry expanding rapidly — especially in Algiers, Oran, Constantine, and Annaba — demand for locally produced roofing sheets is at an all-time high. Machine Matcher helps manufacturers establish or upgrade their facilities with world-class, CE-certified roll forming systems, supported by 24/7 technical service and regional installation partners.

| Specification | Details |

|---|---|

| Machine Type: | Corrugated Metal Roofing Roll Forming Machine |

| Production Speed: | 15–45 m/min (depending on configuration) |

| Material Thickness Range: | 0.3–0.8 mm |

| Material Width Range: | 914–1250 mm |

| Material Types: | Galvanized Steel (GI), Galvalume (AZ), Pre-painted Steel (PPGI), Aluminum |

| Material Yield Strength: | 235–550 MPa |

| Roller Material: | GCr15 bearing steel, hardened and polished |

| Roller Surface Treatment: | Hard chrome plated for anti-corrosion performance |

| Number of Forming Stations: | 16–24 stations (profile-dependent) |

| Roller Shaft Diameter: | 70–85 mm |

| Shaft Material: | 45# precision-ground steel |

| Main Drive Type: | Gearbox or chain drive |

| Power (Algeria): | 380 V / 50 Hz / 3 Phase |

| Motor Power: | 7.5–15 kW (depending on machine speed) |

| Cutting Method: | Hydraulic post-cut or flying shear |

| Blade Material: | Cr12MoV, heat-treated for longevity |

| Control Type: | PLC with touchscreen HMI (Delta / Siemens / Mitsubishi) |

| Operating Mode: | Fully automatic with manual override option |

| De-coiling System: | 3–10 ton manual or hydraulic uncoiler |

| Machine Frame: | 350–400 H-beam welded frame, stress-relieved |

| Thickness of Frame Steel: | 16–20 mm |

| Profile Shape: | Corrugated roofing sheet (customizable wave height) |

| Profile Width and Depth: | Width: 800–1100 mm; Depth: 15–25 mm |

| Length Tolerance: | ±1 mm/m |

| Safety Features: | E-stop system, overload protection, safety covers |

| Protective Covers/Guards: | Transparent or solid covers for safe monitoring |

| Emergency Stop Button: | Fitted at entry, exit, and control console |

| Overload Protection System: | Integrated in motor and hydraulic system |

Automatic stacking and counting system

Servo feeder and encoder synchronization

Hydraulic notching or embossing system

Remote PLC diagnostics (Ewon or PLCRemote)

Dual-decoiler for continuous coil changeover

Coil car and hydraulic tipping device

Quick-change roller system for multiple corrugation types

Sound-insulated enclosure and safety guards

Pre-leveling and feeding section

Automatic lubrication system

Every machine is custom-engineered, tested before dispatch, and delivered with videos, wiring diagrams, and a comprehensive installation manual.

Corrugated roofing sheets are the most commonly used roofing material in North African and Middle Eastern construction, prized for their strength, simplicity, and cost efficiency. The profile’s wave shape provides exceptional rigidity and water drainage.

32/1000 Corrugated Sheet – Standard for roofing and wall cladding

76/18 or 76/25 Wave Type – Traditional corrugation used in agriculture and housing

Custom Corrugated Profile – Built to match your existing designs or project standards

Effective Width: 800–1100 mm

Wave Height: 15–25 mm

Material Gauge: 0.3–0.8 mm

Coil Width: 914–1250 mm

Galvanized Steel (GI): Economical and durable for inland regions

Galvalume (AZ): Excellent corrosion resistance for coastal areas

Pre-painted Steel (PPGI): Color-coated for architectural finishes

Aluminum: Lightweight and anti-rust for specialty roofing

Corrugated metal roofing is widely used throughout Algeria’s construction and infrastructure sectors.

Residential Housing and Urban Roofing

Industrial Warehouses and Factories

Agricultural Buildings and Storage Facilities

Commercial Centers and Logistic Hubs

Infrastructure Projects and Prefabricated Structures

With rising steel fabrication and renewable energy development, many Algerian companies now prefer in-country sheet forming to cut import costs and shorten project delivery times.

Machine Matcher provides reliable systems suited for roofing manufacturers, metal distributors, EPC contractors, and steel structure companies across Algeria and neighboring countries.

Each machine is shipped fully assembled and tested for quick installation and commissioning.

Place the machine on a level, reinforced floor.

Connect the electrical cabinet and hydraulic power unit.

Align the entry guide and feeding system.

Run a test coil and adjust roller alignment.

Calibrate PLC length and encoder settings.

Machine Matcher provides remote installation assistance via video or online PLC connection, as well as on-site commissioning and operator training in Algeria and North Africa.

Routine preventive maintenance ensures optimal forming quality and long machine life.

Clean rollers and feeding guides.

Inspect sensors and encoder readings.

Check hydraulic oil levels and lubrication points.

Tighten bolts and chains.

Inspect cutting blade and roller alignment.

Calibrate length measurement in PLC.

Replace hydraulic seals and oil filters.

Conduct full alignment and safety audit.

Machine Matcher offers:

Remote troubleshooting and technical diagnostics

Spare parts (rollers, bearings, blades, seals)

Preventive maintenance contracts

24/7 worldwide support

Prices vary by automation level, material thickness range, and speed capacity.

| Model Type | Configuration | Approx. Price (USD) |

|---|---|---|

| Basic Model | Manual uncoiler, standard PLC, post-cut | $40,000 – $60,000 |

| Mid-Range Model | Hydraulic uncoiler, servo feeding, flying shear | $60,000 – $85,000 |

| High-End Model | Full servo system, auto stacker, dual-decoiler | $85,000 – $120,000+ |

All quotes include:

Profile drawing confirmation

Test video before shipment

Export documentation and packaging

Optional installation and operator training

Machine Matcher supplies corrugated roof roll forming machines across:

Algeria

Tunisia

Morocco

Egypt

Mauritania

Nigeria

France

Middle East and Europe

All systems meet CE and ISO standards, and can be adapted for 380V or 400V power configurations commonly used in North Africa.

New machines built to your exact profile design

CE and ISO certified manufacturing

24/7 worldwide technical support

Remote PLC access and diagnostics

Fast delivery and installation services

OEM spare parts and maintenance support

Localized solutions for North African conditions

Offices in the UK, USA, and Middle East

Machine Matcher helps you build a reliable, cost-efficient production line that delivers quality corrugated roofing sheets for Algeria’s expanding construction market.

Q1: What is a corrugated roof roll forming machine?

A: It’s a continuous production line that forms steel coils into corrugated roofing sheets through a series of precision rollers and a hydraulic cutting system.

Q2: Can one machine make different corrugation profiles?

A: Yes. We can provide interchangeable roller sets or custom tooling for multiple corrugation designs.

Q3: What materials are best for Algeria’s climate?

A: Galvalume (AZ) and pre-painted steel (PPGI) are ideal for Algeria’s coastal and hot climate due to their superior corrosion resistance.

Q4: How long does installation take?

A: Typically 3–5 working days, including calibration, training, and test production.

Q5: What support does Machine Matcher provide?

A: We offer remote PLC setup, spare parts supply, preventive maintenance, and technician training.

Q6: Can the machine handle high-speed production?

A: Yes. Depending on model configuration, production speeds can reach 45 meters per minute with full automation.

For a detailed quote or technical consultation:

Machine Matcher

Global Roll Forming Machine Specialist

United Kingdom (Main Office)

Phone: +44 20 335 56554

United States

Phone: +1 407 559 7948

Mobile / WhatsApp: +44 7816 972935

Email: [email protected]

Copyright 2026 © Machine Matcher.