To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

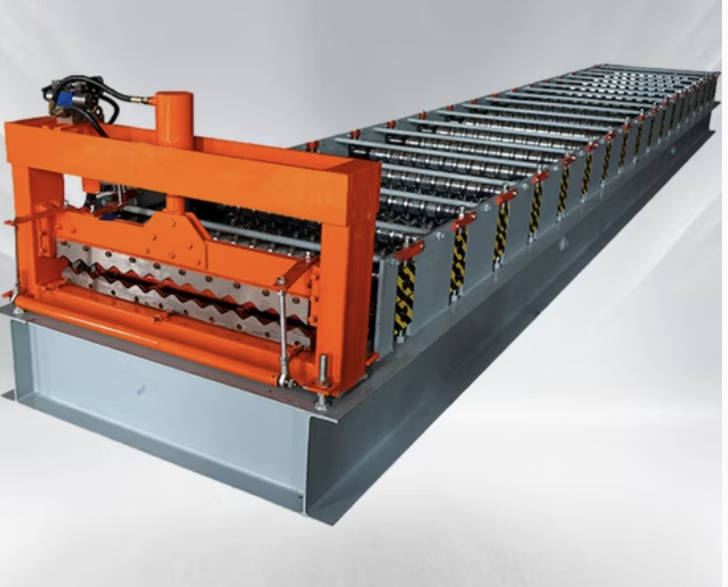

A Corrugated Roll Forming Machine is a specialized equipment used to produce corrugated sheet metal profiles, widely utilized in roofing, cladding, and wall panels. These machines are engineered for precision, speed, and durability, meeting the demands of industrial, residential, and commercial construction sectors.

Corrugated profiles are lightweight, durable, and cost-effective, making them popular in Colombia's rapidly growing construction industry. Whether for rural shelters or urban infrastructure, corrugated sheets offer a versatile solution for roofing and siding applications.

The Corrugated Roll Forming Machine is designed to manufacture high-quality corrugated sheets with consistent profiles. It features robust construction, advanced automation systems, and easy operation. The machine converts metal coils into corrugated profiles through a series of rollers, ensuring accuracy and efficiency.

| Component | Details |

|---|---|

| Material | Galvanized Steel, Aluminum, Pre-Painted Steel, etc. |

| Material Thickness | 0.3mm – 0.8mm |

| Working Speed | 10-15 meters per minute (adjustable) |

| Roller Material | High-grade steel with chrome coating for corrosion resistance |

| Roller Stations | 18-22 stations (varies by model) |

| Frame Structure | Heavy-duty steel frame with welded construction |

| Motor Power | 5.5 kW – 7.5 kW |

| Cutting System | Hydraulic cutting with precision blades |

| Control System | PLC system with touch screen interface |

| Profile Width | 914mm – 1250mm (customizable) |

| Machine Dimensions | 7000mm (L) x 1500mm (W) x 1500mm (H) |

| Voltage | 380V, 50Hz (customizable for Colombia’s power supply) |

Corrugated sheets produced by this machine are widely used in Colombia for:

A1: The machine is compatible with galvanized steel, aluminum, pre-painted steel, and other metals within the thickness range of 0.3mm to 0.8mm.

A2: Yes, the machine can be tailored to produce specific corrugated profiles based on customer requirements.

A3: The machine operates at a speed of 10-15 meters per minute, adjustable based on material and profile specifications.

A4: Yes, the machine’s voltage can be customized to match Colombia’s standard of 380V, 50Hz, or any other specification.

A5: Installation typically takes 3-5 days, depending on the site and readiness.

A6: The machine comes with a standard 1-year warranty, covering parts and labor for manufacturing defects.

A7: Key industries include construction, agriculture, and manufacturing sectors that require roofing, cladding, or fencing solutions.

Copyright 2026 © Machine Matcher.