To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

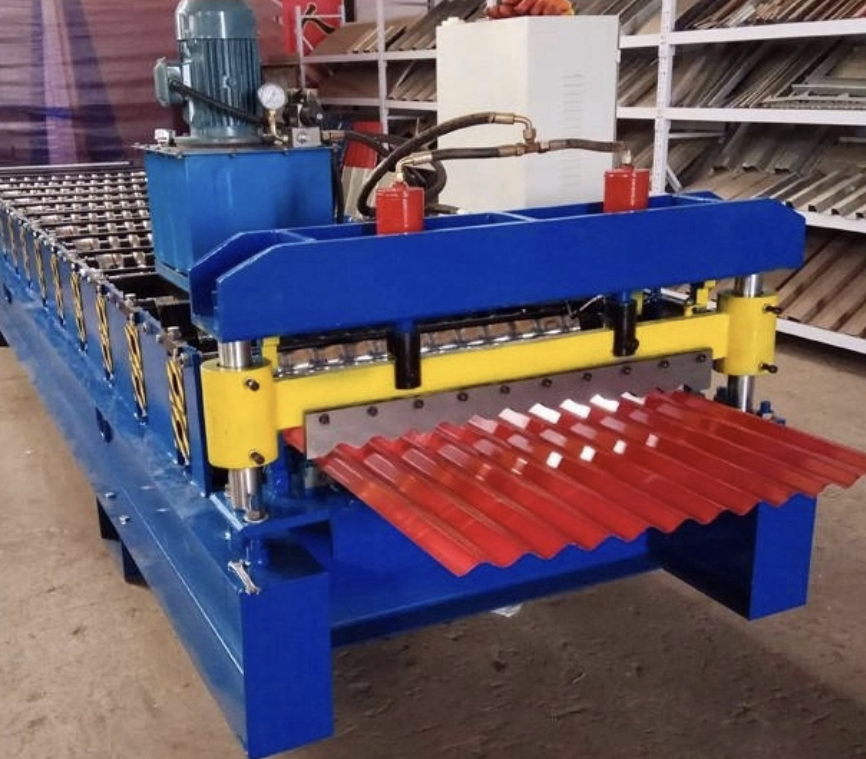

[High Efficiency]6m per minute.Produce 2880m per shift for 8 hours one day.

[Long Life Machine]Rollers of machine are CNC machine tooled, plated with 0.05mm hard chrome on surface.Heat treatment for cutting frame to remove the steel stress, to avoid deformation. Cutting material is Cr12 mould steel with quenched treatment, all these processing steps ensure machine long life time.

[High Precision]Shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

[Automatic & Easy Operate]Safe and easy to operate with Mitsubishi PLC touch screen operating system.Friendly man-machine interaction.

[Excellent Services]Technician can be sent to your factory to install the machine and train your workers. Engineers are able to service overseas.We supply lifetime services for our machines.

|

Decoiler |

Capacity:5 tons |

|

Material |

Steel Coil |

|

Thickness |

0.3-0.8mm |

|

Transmission |

Chain/Gear/Gearbox |

|

Speed |

10-15m/min |

|

Roller |

Steel with quenched treatment,chromed on the surface |

|

Shaft |

steel with tempering treatment |

|

Cutting type |

Hydraulic cutting |

|

Cutting material |

Cr12 with quenched treatment Hardness58°-62° |

|

Welding |

Automatic spot welding |

|

Control system |

PLC |

|

Electric brand |

Delta,Siemens,Schneide |

|

Voltage |

380V,50HZ,3PH(or as customers' request) |

Copyright 2026 © Machine Matcher.