To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

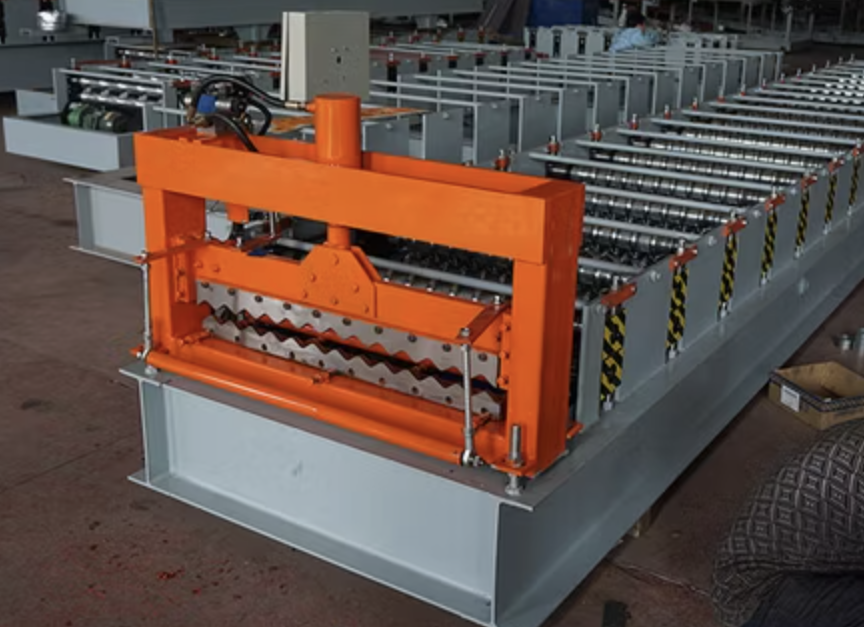

The Corrugated Steel Panel Roll Forming Machine is an advanced industrial tool designed to produce corrugated steel panels efficiently and with precision. These panels are widely used in roofing, wall cladding, and industrial construction due to their durability, strength, and lightweight properties. The machine transforms metal coils into corrugated profiles by a continuous process of feeding, forming, and cutting to the desired length.

This machine is highly automated, ensuring consistent quality, minimal material wastage, and high production speeds. It is suitable for various materials, including galvanized steel, aluminum, and coated steel.

1. What materials can this machine process?

The Corrugated Steel Panel Roll Forming Machine can process galvanized steel, aluminum, coated steel, and other materials with thicknesses ranging from 0.3mm to 0.8mm.

2. What are the power requirements?

The standard power requirement is 380V, 50Hz, 3-phase. However, the machine can be customized to other power standards depending on the customer's location.

3. Can the machine produce panels of different lengths?

Yes, the length of the panels can be adjusted easily via the PLC system, which ensures precise cutting as per the desired dimensions.

4. Is training provided for operating the machine?

Yes, training is typically included during installation. The user-friendly interface also makes it easy to learn and operate the machine.

5. What is the average production speed?

The production speed is approximately 20–30 meters per minute, depending on the material and panel specifications.

6. What are the maintenance requirements?

Maintenance is minimal and includes regular lubrication, blade sharpening, and routine checks of the electrical and hydraulic systems.

7. Can the machine be upgraded with additional features?

Yes, optional extras such as pre-punching systems, automatic stackers, and advanced coil handling systems can be integrated based on customer needs.

8. What industries commonly use the panels produced by this machine?

The panels are widely used in construction, agriculture, and industrial applications for roofing, wall cladding, and structural purposes.

Copyright 2026 © Machine Matcher.