To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

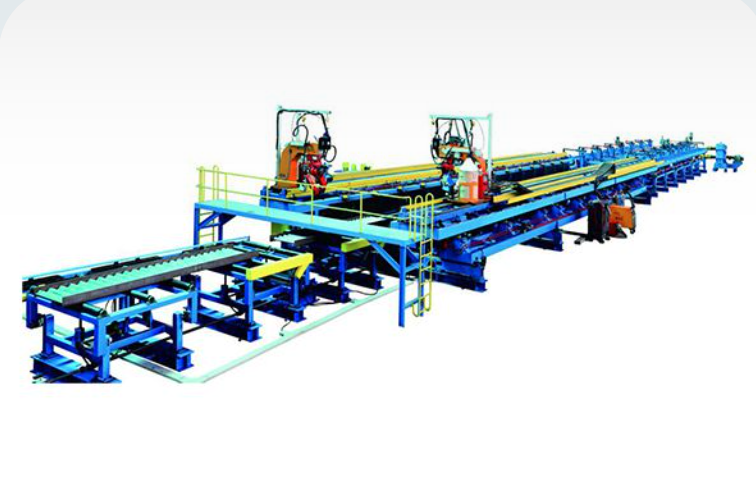

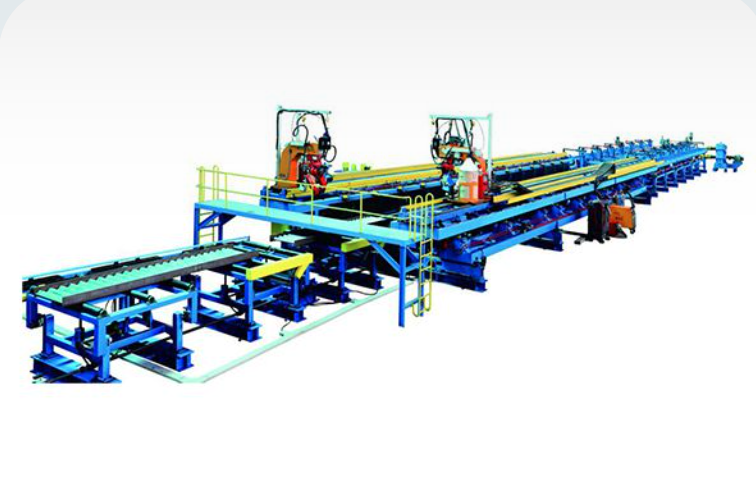

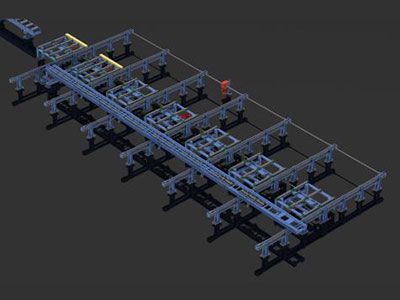

The JBH corrugated web automatic H-beam welding line developed by our company consists of slitting and cut to length machine, web forming machine, flange and web feeding machine, corrugated web H-beam robot automatic welding machine, cross-section cutting machine, outfeed system and so on. The corrugated web H-beam automatic welding machine adopts the welding robot introduced from Italy which automatically controls the works such as laser scanning of entire welding line, two positions welding, welding gun changing, cross-section cutting and so on. This welding line features high quality, high efficiency, full-automation and so on.

Production Line Components

Web forming machine: This machine consists of upper and lower rollers, through the power input machine to drive the rollers rotation. The roll forming speed can be adjusted by the frequency control. Lower roller is fixed, and upper roller can be lifted. Through adjusting motor, while the lifting device adjusts the distance between upper and lower rollers, to get the required corrugated surface. The adjustment is automatically controlled by PLC system.

Flange and web feeding machine

This machine is used to transport the corrugated sheet to the welding machine, and it is equipped with sheet lateral moving device. Left and right flange transmission units are symmetrical parts, the main function of these units is to transport the flange to the welding machine. The frame adopts lifting device, and reduction motor drive.

Corrugated web H-beam automatic robot welding machine

Corrugated web H-beam welding machine adopts the welding robot introduced from Italy which automatic controls the works such as whole line laser scanning, two positions welding, welding gun changing, and cross-section cutting and so on. This machine can weld the cross-section of corrugated H-beam too.

Cross-section cutting & outfeed equipment

This machine is mainly used to outfeed the finished H-beam. Longitudinal transmission device can be adjusted according to different work-pieces flange height, and the finished H-beam is lowered to lateral table and then fedout.

| Item | Parameter | ||||

| Corrugated web forming machine | Suitable raw material | Yield strength(Mpa) | ≤345 | ||

| Steel thickness(mm) | 2-6(≤235Mpa): 2-4(≤345Mpa) | ||||

| Steel width (mm) | 350-1500 | ||||

| Profile dimension | Wave height(mm) | 40-50 | |||

| Distance of waves(mm) | 约155(About)155 | ||||

| Steel feeding mode | Conveyor | ||||

| Corrugate web outfeed mode | Transmission chain | ||||

| Feeding power (kw) | 30 | ||||

| Total weight(T) | (About)11 | ||||

| Dimension(mm) 6235×1640×2500 | |||||

| Work-piece dimension(mm) | Work-piece length | 4000-20000 | ||

| Web thickness | 2-6 | |||

| Web height | 350-1500 | |||

| Flange thickness | 10-30 | |||

| Flange width | 150-500 | |||

Copyright 2026 © Machine Matcher.