To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Supplied by Machine Matcher

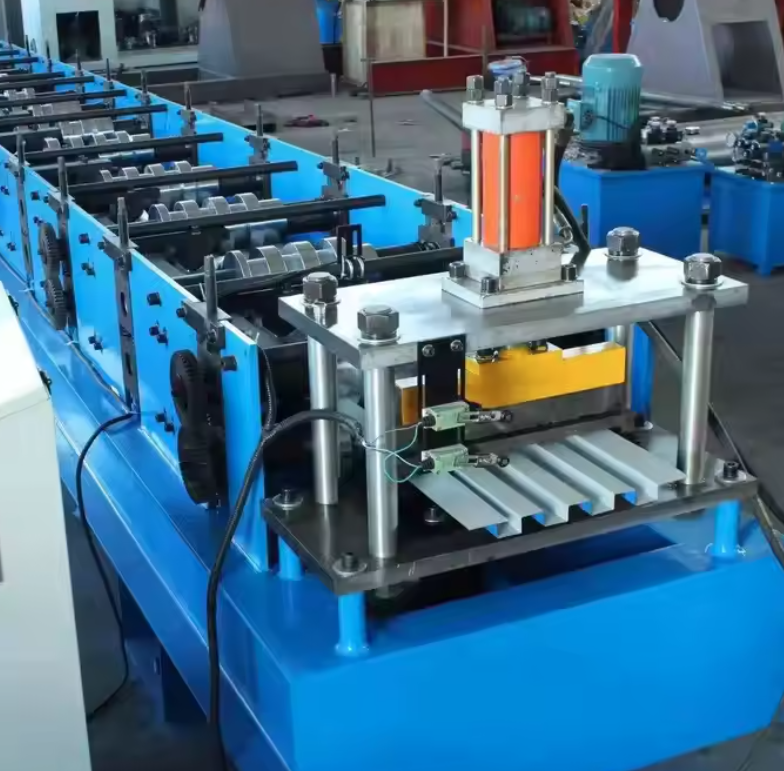

Machine Matcher proudly offers the Curtain Wall Panel Roll Forming Machine, engineered for the unique demands of the United Arab Emirates' construction and manufacturing sectors. This machine is designed to produce high-precision curtain wall panels, essential for modern architectural facades, ensuring durability and aesthetic appeal in the UAE's challenging climate conditions.

Machine Type: Curtain Wall Panel Roll Forming Machine

Production Speed: 15–30 meters per minute

Material Thickness Range: 0.3 mm – 0.8 mm

Material Width Range: Up to 1250 mm

Material Types: Galvanized Steel (GI), Pre-painted Galvanized Steel (PPGI), Aluminum

Material Yield Strength: Up to 550 MPa

Roller Material: High-Grade 45# Steel

Roller Surface Treatment: Hard Chrome Coating

Number of Forming Stations: 16–24 stations (depending on profile design)

Roller Shaft Diameter: 70 mm

Shaft Material: Solid 45# Steel, heat-treated

Main Drive Type: Chain Drive or Gearbox Drive

Power (UAE Standard): 380V, 50Hz, 3 Phase (customizable)

Motor Power: 7.5 kW – 11 kW (based on requirements)

Cutting Method: Hydraulic Cutting (post-cut)

Blade Material: Cr12Mov (hardened steel)

Control Type: PLC Automatic Control System (Siemens, Delta, or Mitsubishi)

Operating Mode: Full Automatic with touch screen HMI

De-coiling System: Manual or Hydraulic Decoiler (3–5 Ton capacity)

Punching/Notching System: Optional hydraulic punching/notching station available

Machine Frame: Heavy-duty welded H-Beam steel frame

Thickness of Frame Steel: 18–22 mm

Profile Shape: Customizable curtain wall panel profiles

Profile Width and Depth: Based on customer-provided drawings

Length Tolerance: ± 2 mm

Safety Features:

Protective Covers/Guards: Included around moving parts

Emergency Stop Button: Installed at multiple accessible points

Overload Protection System: Integrated into the electrical system

The Curtain Wall Panel Roll Forming Machine caters to a diverse range of industries in the UAE, including:

Construction and Building: Production of curtain wall panels for residential, commercial, and industrial buildings.

Metal Fabrication: Manufacturing of metal components for various applications.

Oil & Gas Infrastructure: Fabrication of panels for shelters and storage facilities.

Logistics and Warehousing: Creation of wall panels for warehouses and logistics centers.

Construction: Producing curtain wall panels that provide both structural support and aesthetic appeal for modern buildings.

Metal Fabrication: Creating customized metal panels for specialized industrial applications.

Oil & Gas: Manufacturing durable panels suitable for harsh environments in oil and gas facilities.

Warehousing: Generating wall panels that meet the specific requirements of storage and distribution centers.

Machine Matcher offers extensive customization to meet your specific production needs:

Profile Design: Tailored to your unique curtain wall panel specifications.

Material Compatibility: Adjustments to accommodate different material types and thicknesses.

Automation Level: Options for manual, semi-automatic, or fully automatic operation.

Additional Features: Inclusion of punching/notching systems, stackers, and advanced control systems.

Precision Engineering: Ensures consistent quality and accuracy in panel production.

Robust Construction: Built with high-grade materials for longevity and reliability.

Energy Efficiency: Optimized power consumption reduces operational costs.

User-Friendly Interface: Intuitive controls for ease of operation and minimal training requirements.

Comprehensive Support: Backed by Machine Matcher's full suite of services, including installation, maintenance, and repair.

Q: Can the machine be customized for our specific curtain wall panel profile?

A: Yes, Machine Matcher specializes in customizing machines to match your exact profile requirements.

Q: What materials are compatible with this machine?

A: The machine can process Galvanized Steel (GI), Pre-painted Galvanized Steel (PPGI), and Aluminum, with thicknesses ranging from 0.3 mm to 0.8 mm.

Q: Is remote installation support available?

A: Yes, we offer remote video guidance, and on-site installation is available upon request.

Q: What is the lead time for manufacturing and shipping?

A: Production typically takes 30–60 days, and shipping time depends on the destination port.

Q: What affects the final price of the machine?

A: Pricing is determined based on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

Prices Start From: Approximately $60,000 USD.

Note: Final pricing is influenced by customization options, additional features, and specific requirements.

All machines are covered by a one-year warranty from the dispatch date, including durable maintenance and repair support.

Machine Matcher delivers to all locations within the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, Ajman, Fujairah, Ras Al Khaimah, and Umm Al Quwain.

For a personalized quote or to discuss your specific requirements, please email your profile drawings and details to:

Email: [email protected]

All machines are supplied by Machine Matcher, ensuring consistent branding, expert support, and dedicated service for all your roll forming needs.

Copyright 2026 © Machine Matcher.