To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

|

8-15 |

Not include the time of cutting |

|

|

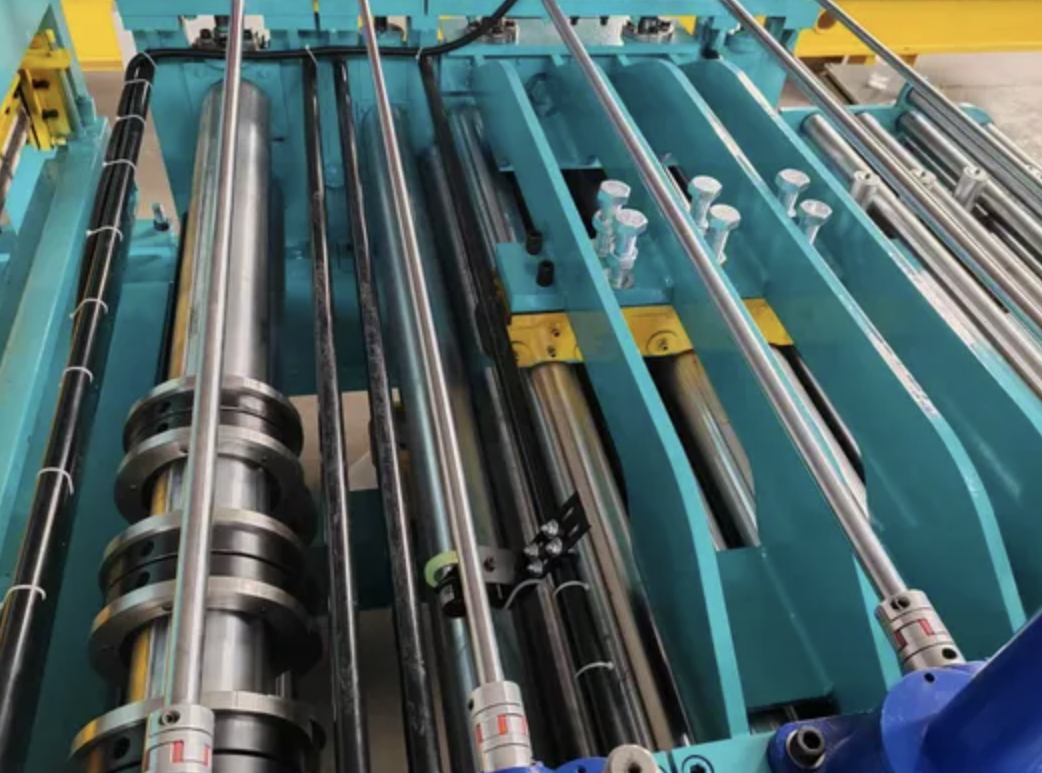

Forming stations |

upper4 buttom 5 |

|

|

Thickness of structure |

16mm |

|

|

Forming shaft diameter(mm) |

90 |

|

|

transmission |

gear |

|

|

Sleeve |

galvanized pipe with color coating |

|

|

Type of cutting |

Roll formed and length-set cutting |

|

|

Control system |

PLC Panasonic Inverter |

|

|

Install dimension(depend on the final design) |

2.2m×1.35m×1.2m |

|

|

Total weight (Approx) |

1.5T |

A Cut-to-Length (CTL) Line Machine is essential in metal processing, designed to uncoil, straighten, measure, and cut metal sheets from a coil into flat sheets of specified lengths. These machines are commonly used in industries where precision and efficiency in sheet metal cutting are required, such as in automotive, construction, and appliance manufacturing. Here’s a quick overview of how they work and the benefits they offer:

Copyright 2026 © Machine Matcher.