To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

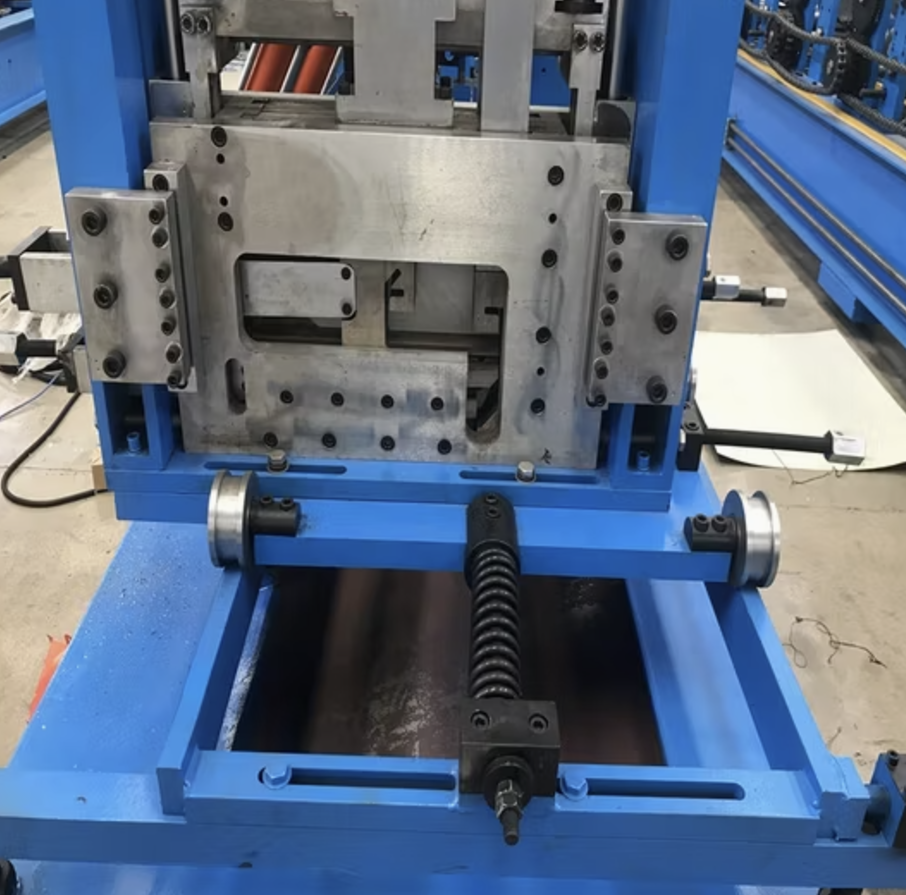

CZ Purlin Roll Forming Machines are specialized equipment designed to produce C and Z-shaped purlins used in the construction of steel structures, warehouses, industrial buildings, and roofing systems. In Argentina, the demand for high-quality roll-forming machines is growing due to the robust construction industry and the increasing need for durable steel components.

A CZ Purlin Roll Forming Machine is a fully automated system that efficiently produces C and Z purlins by adjusting the rollers and cutting dies. These machines are equipped with advanced technology to switch between C and Z profiles without manual intervention, making them highly versatile and time-saving.

| Specification | Details |

|---|---|

| Roller Material | High-grade steel with chrome plating for durability and precision |

| Profile Thickness | 1.5 mm to 3.0 mm |

| Profile Width | 80 mm to 300 mm |

| Profile Height | 30 mm to 80 mm |

| Machine Speed | 10-15 meters per minute |

| Cutting System | Hydraulic cutting system with high precision |

| Control System | PLC control with touchscreen operation |

| Motor Power | 15 kW to 20 kW |

| Hydraulic Power | 5.5 kW |

| Switching Mechanism | Automatic C and Z profile switching |

| Frame Structure | Heavy-duty welded steel frame |

| Power Supply | 380V/50Hz (customizable for Argentina’s grid standards) |

| Optional Extras | Pre-punching system, remote control operation, stackers, and leveling units |

A: The primary function is to produce C and Z-shaped steel purlins used in constructing steel structures.

A: The machine uses an automatic mechanism controlled by a PLC system to adjust rollers and cutting dies for seamless switching.

A: Industries such as construction, warehousing, and roofing frequently use CZ purlins due to their structural strength and versatility.

A: The price typically ranges from $30,000 to $80,000 depending on specifications and additional features.

A: Regular lubrication of rollers, checking hydraulic systems, cleaning cutting dies, and periodic inspection of electrical components.

A: Yes, many machines can be customized to produce specific profile sizes and thicknesses.

A: Depending on the supplier and shipping method, it typically takes 6-12 weeks.

Copyright 2026 © Machine Matcher.