To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

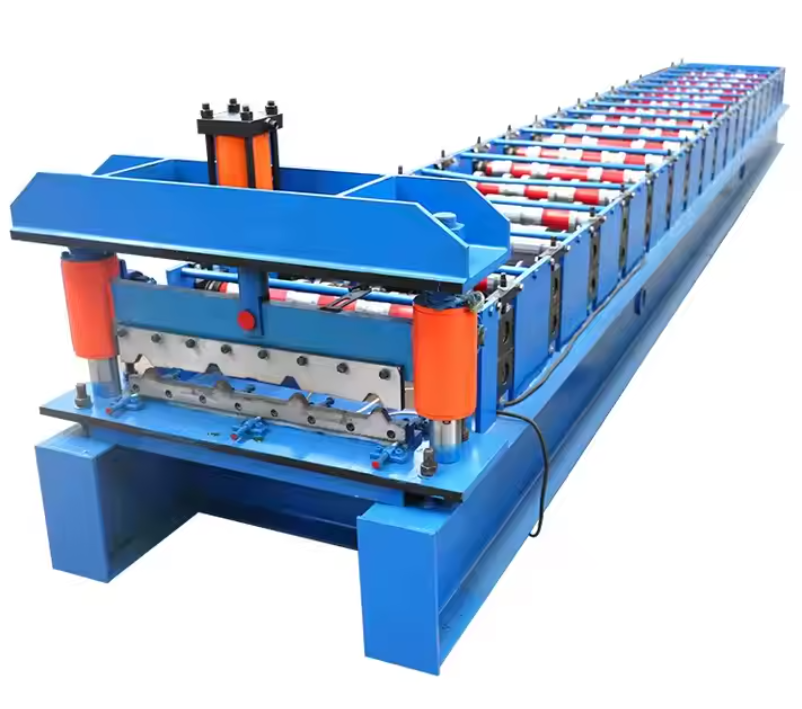

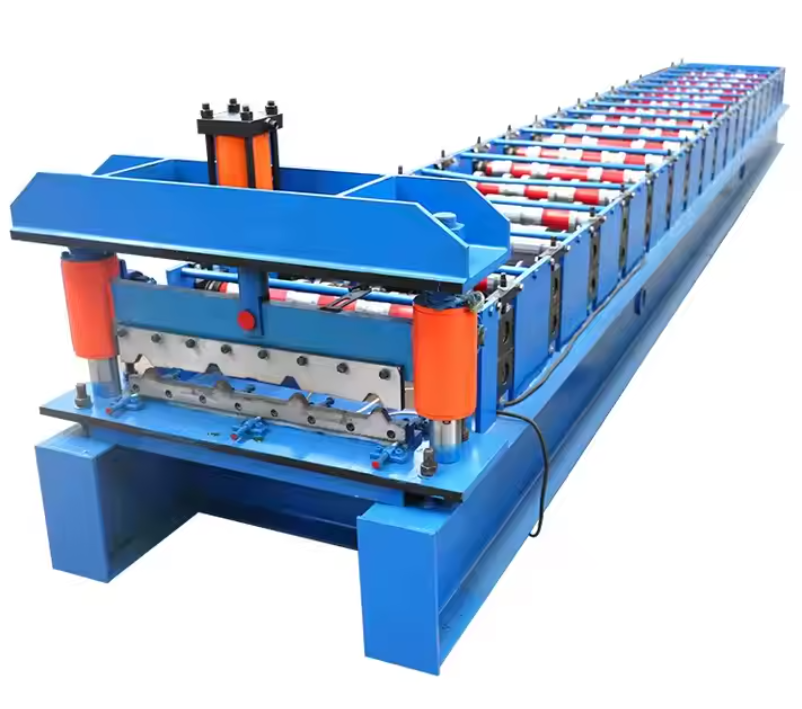

Deep Rib Roof Deck Roll Forming Machine – UAE Edition

Engineered for Heavy-Duty Steel Decking Projects Across the United Arab Emirates

The Deep Rib Roof Deck Roll Forming Machine is a high-performance, precision-built system designed to produce deep-profile structural roof decking for commercial, industrial, and high-rise building projects. This machine is specifically tailored to meet the demands of the UAE construction industry, which relies heavily on robust, load-bearing steel decking to support roofing systems in a hot, dry, and wind-prone environment.

Known for its deep-profiled structural shape, the deck produced by this machine provides exceptional strength, load distribution, and diaphragm rigidity, making it ideal for multi-storey car parks, warehouses, office towers, and airport terminals across Abu Dhabi, Dubai, and Sharjah.

Machine Matcher proudly supplies this equipment custom-built and fully compatible with UAE voltage standards and local job site requirements. Every machine includes after-sales technical support, setup guidance, and a 1-year warranty from dispatch.

This Deep Rib Roof Deck machine is widely used across:

Construction & Infrastructure Development

High-Rise Commercial Buildings

Prefabricated Steel Structures

Industrial Roof Systems

Multi-storey Car Parks and Warehouses

It is essential for developers and contractors looking to install high-strength metal decking systems that support waterproofing membranes, concrete slabs, and insulation.

| Specification | Details |

|---|---|

| Machine Type | Deep Rib Roof Deck Roll Forming Machine |

| Production Speed | 15–30 meters per minute |

| Material Thickness Range | 0.75mm – 1.5mm |

| Material Width Range | 1000mm – 1450mm (customized to profile) |

| Material Types | Galvanized Steel (GI), Cold-Rolled Steel, Galvalume, Aluminum |

| Material Yield Strength | Up to 550 MPa |

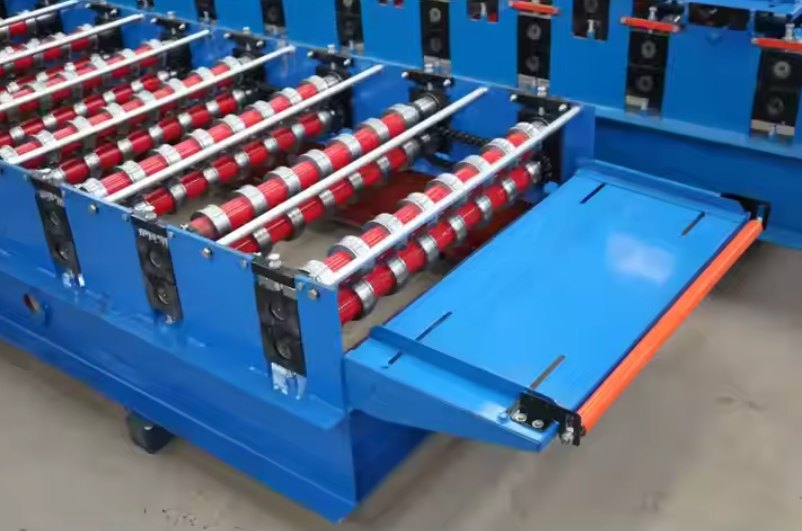

| Roller Material | GCr15 bearing steel with precision CNC machining |

| Roller Surface Treatment | Hard chrome plated (≥0.05mm thickness) |

| Number of Forming Stations | 20–28 stations (depending on profile complexity) |

| Roller Shaft Diameter | 80mm |

| Shaft Material | High-grade 45# steel, heat-treated |

| Main Drive Type | Gearbox transmission |

| Power (UAE Standard) | 380V / 50Hz / 3Phase |

| Motor Power | 15–22 kW main motor (based on profile type and production speed) |

| Cutting Method | Hydraulic post-cutting with stop-cut and flying cut options available |

| Blade Material | Cr12MoV, heat-treated for durability |

| Control Type | PLC automatic control (Siemens, Delta, or Mitsubishi options) |

| Operating Mode | Automatic with touchscreen HMI interface |

| De-coiling System | 5–10 ton hydraulic or manual uncoiler |

| Punching/Notching System | Optional hydraulic punching system (for service holes/vents) |

| Machine Frame | Welded structure with heavy-duty H-beams |

| Thickness of Frame Steel | 20–25mm |

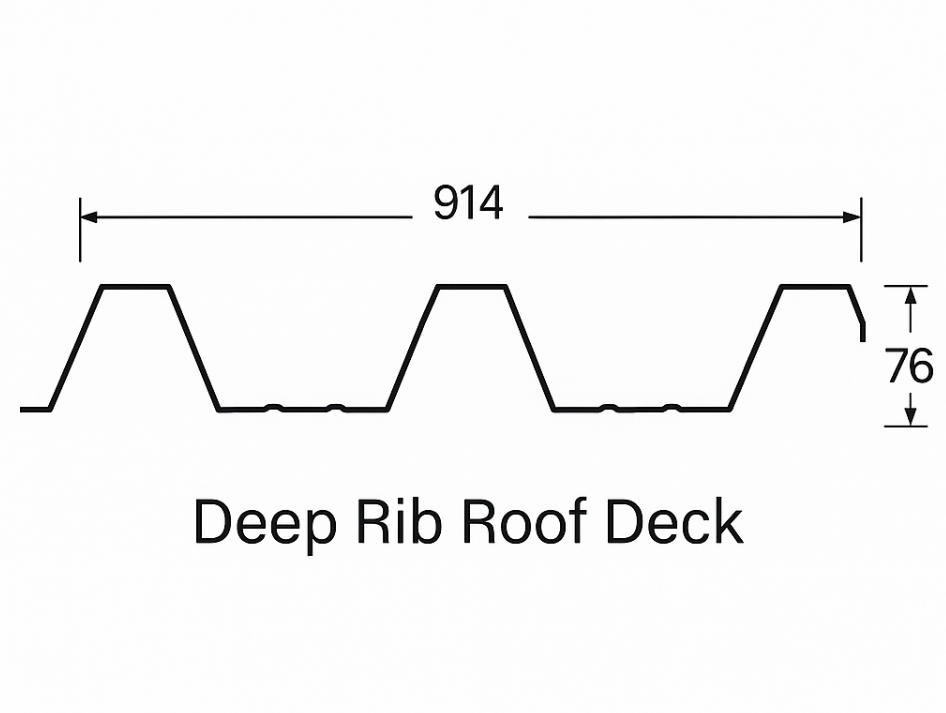

| Profile Shape | Deep Rib (3" – 4" depth depending on customer drawing) |

| Profile Width and Depth | Effective width: ~914–1000mm; Depth: ~76–102mm |

| Length Tolerance | ±2mm per 6000mm |

| Safety Features | Emergency stop, overload protection, full steel guards, safety signs |

| Protective Covers/Guards | Included for all rotating components |

| Emergency Stop Button | Installed on HMI and frame |

| Overload Protection System | Integrated with main electrical control panel |

Prices start from:

$65,000 USD for a standard configuration (excluding optional extras and shipping).

What affects the final price?

Profile complexity and depth

Type of automation (manual vs automatic stacker, servo feeder, punching tools)

Brand of PLC system

Motor and gearbox capacity

Optional extras: Coil car, hydraulic punch stations, remote operation features

Local voltage customization and region-specific adaptations (UAE standard)

Machine Matcher provides tailored quotes based on your profile drawing, coil specs, and job site needs.

Please send all specifications and drawings to: [email protected]

This machine is new and custom-built to meet your specific production needs. It can be delivered anywhere in the United Arab Emirates, including:

Abu Dhabi

Dubai

Sharjah

Ras Al Khaimah

Ajman

Al Ain

All machines are backed by a full 1-year warranty, with support for setup, remote diagnostics, and on-site maintenance options available upon request.

Q1: What makes the deep rib profile different from other roof decks?

A: The deep rib design (typically 3" or more) offers increased structural capacity, better load distribution, and enhanced diaphragm action, making it ideal for longer spans and heavy-duty applications.

Q2: Can this machine handle aluminum or stainless steel?

A: Yes, with the right tooling and adjusted forming speeds, the machine can handle aluminum and stainless steel. Contact us with your material type for a tailored configuration.

Q3: Is setup included in the price?

A: Initial remote support for setup is included. On-site installation and training are available at an additional cost depending on your UAE location.

Q4: What kind of maintenance does this machine require?

A: Routine lubrication of the forming shafts, regular inspection of the cutting blades, electrical checks, and cleaning of roller surfaces. Preventative maintenance packages are available.

Q5: What are the customization options?

A: You can request custom profile shapes, additional punch tooling, servo feeding systems, or even dual-profile forming capability on a single line.

Q6: What’s the delivery time?

A: Standard production time ranges from 8 to 12 weeks, depending on order complexity. Delivery to UAE ports is arranged with customs support if needed.

If you're looking to produce heavy-duty deep ribbed roof deck panels in the UAE for high-rise and industrial construction projects, this machine delivers both precision and reliability. Built with premium components and fully compliant with UAE electrical and safety standards, it's the perfect investment for fabricators, contractors, and steel structure manufacturers across the Emirates.

To receive a personalized quote and discuss your profile requirements, contact us at:

[email protected]

Copyright 2026 © Machine Matcher.