To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

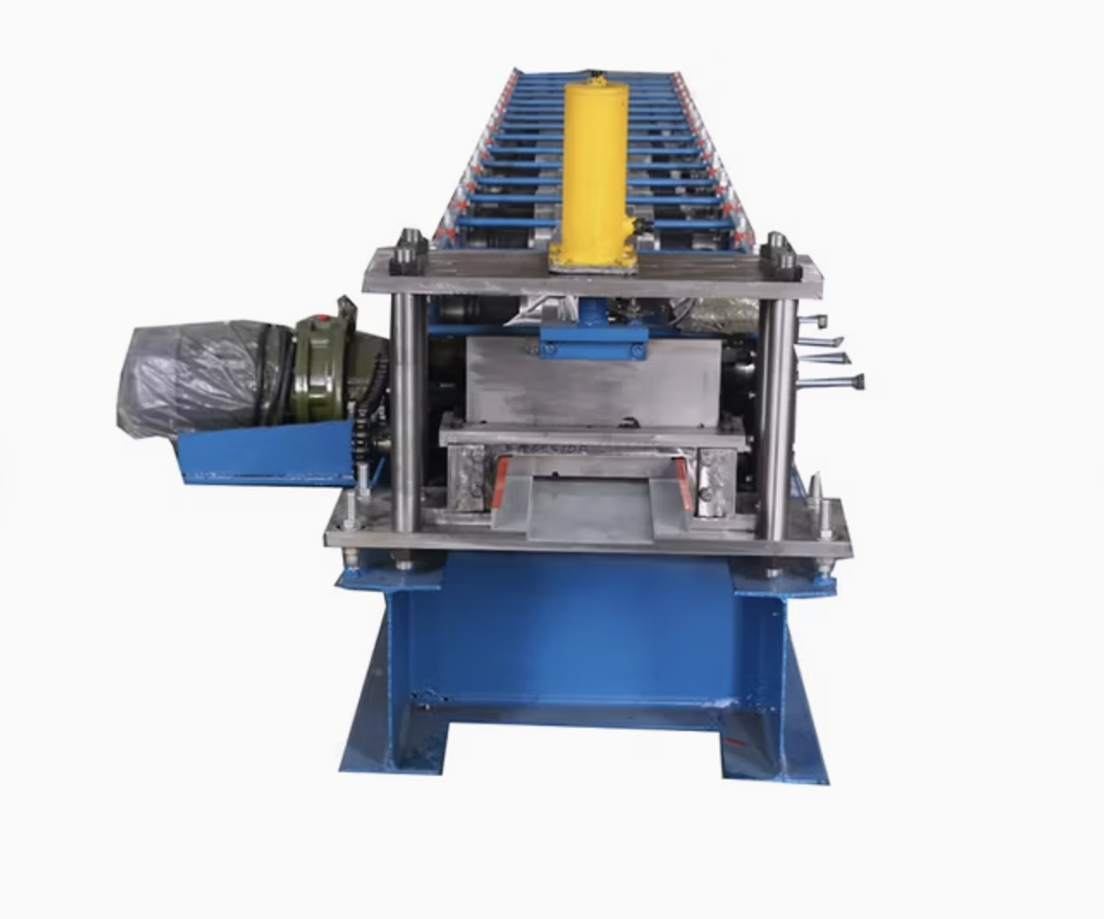

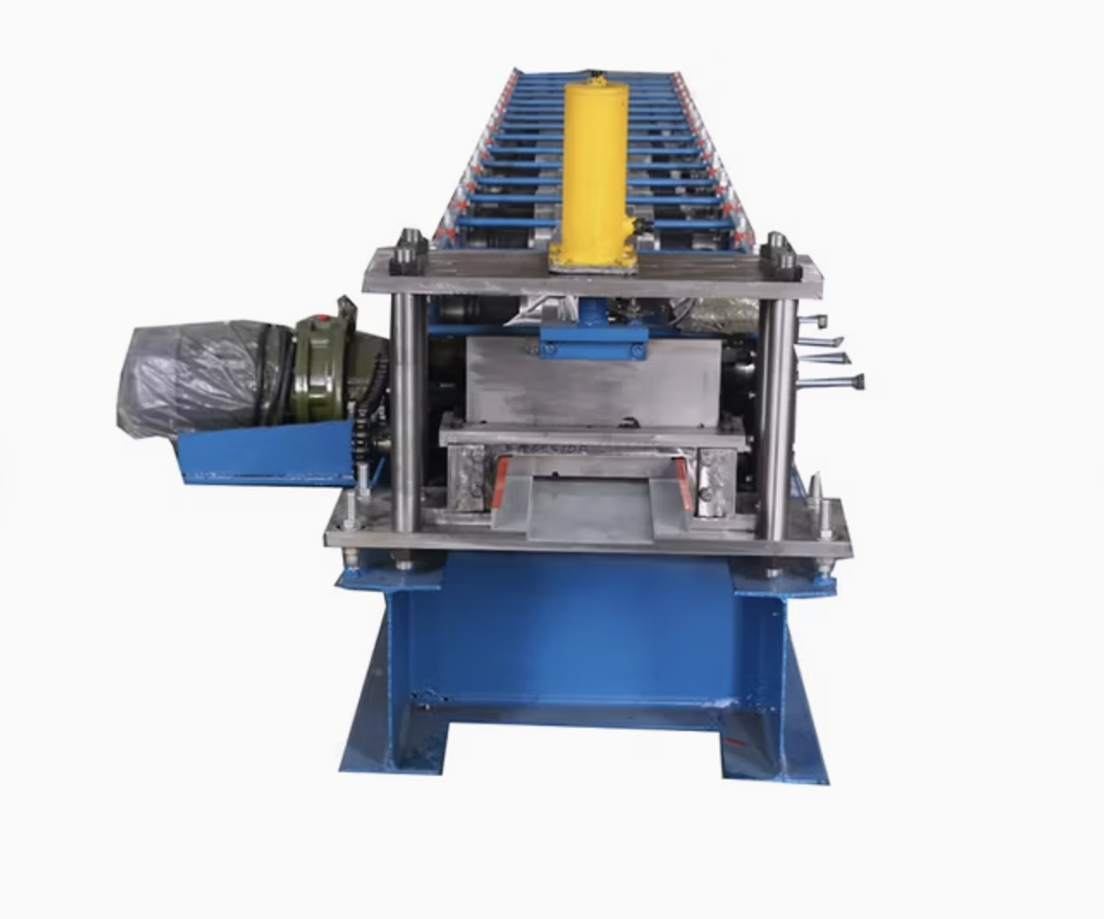

A door frame roll forming machine is a specialized equipment designed to produce metal door frames efficiently and accurately. These machines are essential in manufacturing high-quality door frames used in residential, commercial, and industrial applications. Known for their versatility, precision, and high-speed production, door frame roll forming machines are tailored to meet specific customer needs, including varying profile designs, materials, and production scales.

The machine operates by feeding a steel or aluminum coil into a series of rollers that gradually form the material into the desired door frame profile. With advanced automation systems, including a PLC control system, these machines deliver consistent output while minimizing manual intervention.

Q1: What materials can be processed with a door frame roll forming machine?

A1: These machines are designed to process galvanized steel, stainless steel, aluminum, and pre-painted steel. The choice of material depends on the end-use application.

Q2: What is the average production capacity?

A2: A typical machine can produce up to 20 meters of door frame profiles per minute, depending on the complexity of the design and material thickness.

Q3: How can I ensure compliance with German safety standards?

A3: When purchasing, ensure the machine is CE-certified and includes essential safety features such as emergency stops and protective enclosures.

Q4: Are these machines customizable?

A4: Yes, most manufacturers offer customization options, including profile design, material handling systems, and automation levels.

Q5: What is the maintenance requirement for these machines?

A5: Regular maintenance involves cleaning the rollers, checking the lubrication system, inspecting the hydraulic system, and calibrating the PLC control system.

Q6: What should I look for in a supplier?

A6: Choose a supplier with a proven track record, excellent customer reviews, and after-sales support, including spare parts availability and technical assistance.

Q7: Can these machines be upgraded for future needs?

A7: Yes, many manufacturers provide upgrade kits, allowing you to add features like servo-driven punching or automatic stacking systems.

Copyright 2026 © Machine Matcher.