To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

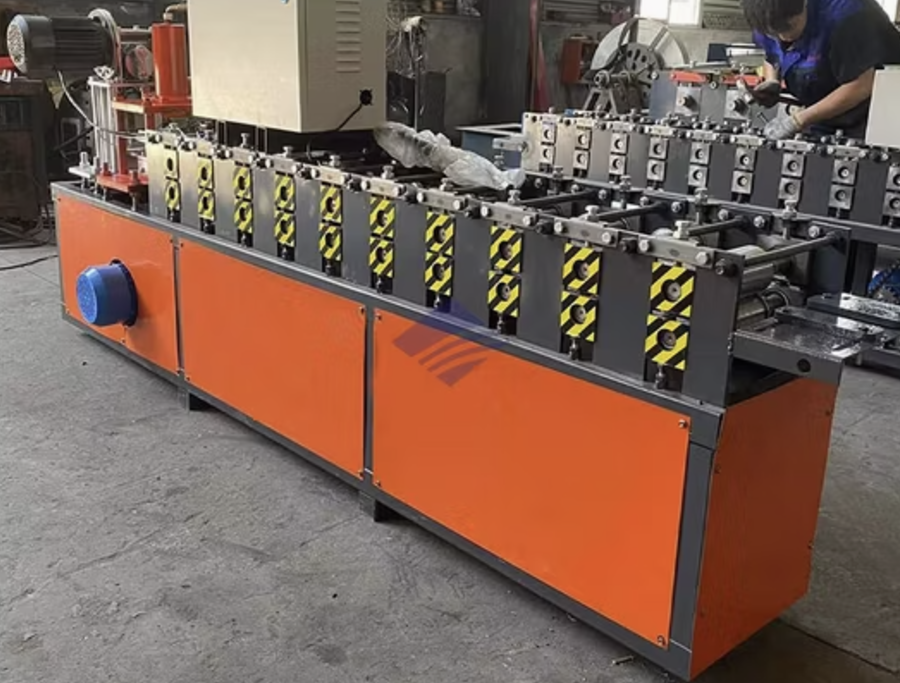

Door frame roll forming machines are specialized equipment designed to manufacture high-quality, precise, and durable door frames efficiently. These machines are widely used in the construction and manufacturing industries, catering to residential, commercial, and industrial needs. This article delves into the specifications, functionality, and benefits of door frame roll forming machines, with a focus on their application in Canada.

A door frame roll forming machine is engineered to create door frame profiles through a continuous bending operation. It processes metal strips into a specified shape, offering precision and consistency. The machine integrates advanced technology to ensure high productivity, low waste, and adaptability to various door frame designs.

The machine setup involves:

Q1. What materials can a door frame roll forming machine process?

A: These machines can process materials like galvanized steel, aluminum, stainless steel, and cold-rolled steel, typically with a thickness range of 0.5mm to 2.0mm.

Q2. Is this machine suitable for Canadian power standards?

A: Yes, door frame roll forming machines can be customized to match Canadian power requirements, such as 380V/50Hz or 220V/60Hz.

Q3. Can the machine produce different door frame profiles?

A: Yes, the machine can be customized to produce a variety of profiles, including plain, reinforced, and decorative designs.

Q4. What is the production capacity of the machine?

A: The production speed ranges from 10-20m/min, depending on the material type and profile complexity.

Q5. What industries in Canada commonly use these machines?

A: Door frame roll forming machines are widely used in construction, manufacturing, and real estate development industries.

Q6. Are there financing options available for purchasing in Canada?

A: Many suppliers offer flexible financing options, including lease-to-own and installment plans, tailored for Canadian buyers.

Q7. How long does it take to install and start production?

A: Installation and setup typically take 3-5 days, including operator training.

Q8. Can the machine handle high-volume production?

A: Yes, the machine is designed for high-volume production while maintaining quality and precision.

Investing in a door frame roll forming machine in Canada ensures efficient, precise, and scalable production of door frames. With customizable options, high performance, and robust construction, this machine is an asset to industries aiming for streamlined manufacturing processes.

Copyright 2026 © Machine Matcher.