To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

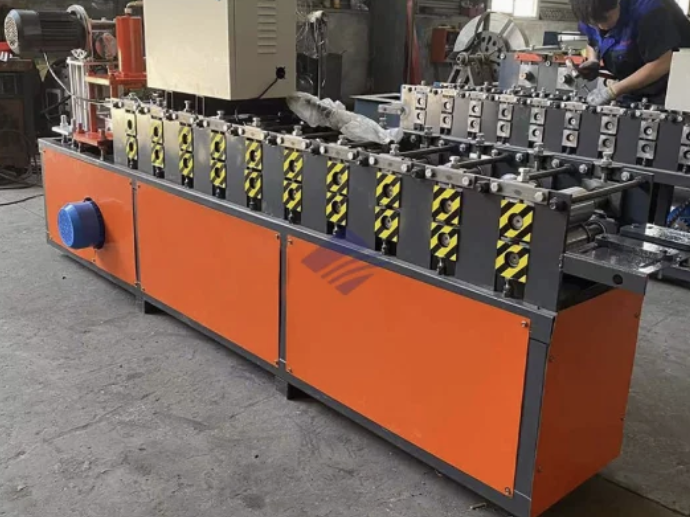

A door frame roll forming machine designed for Egypt should cater to the specific requirements of the market, which may include considerations for material durability, precise frame measurements, and energy efficiency. Here's a detailed overview of typical specifications and features that would suit buyers in Egypt:

Copyright 2026 © Machine Matcher.