To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

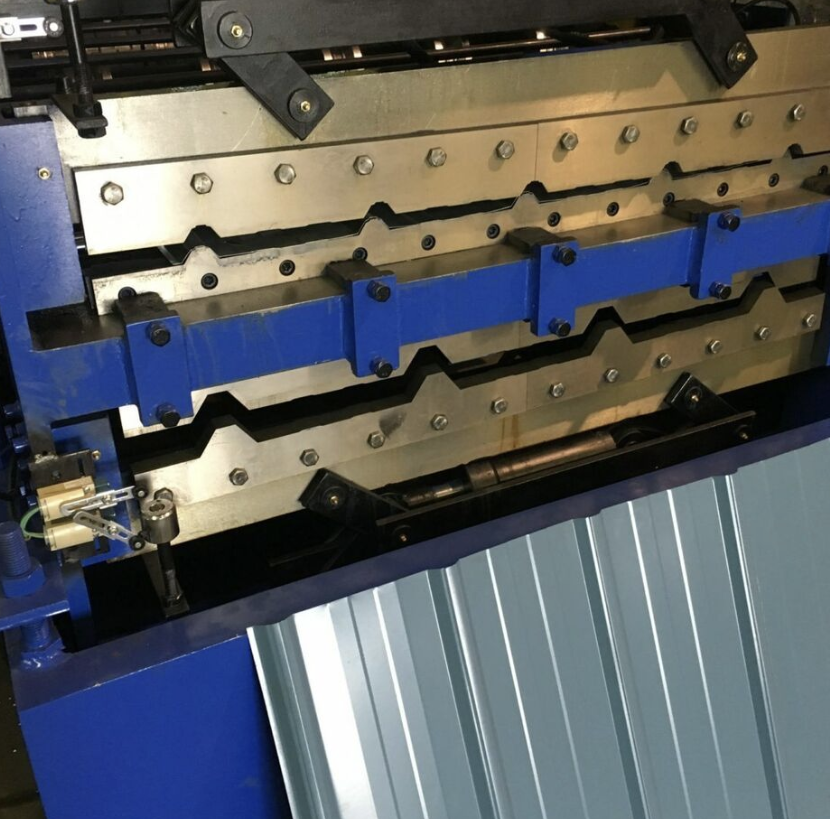

Double deck roll forming machines are innovative and space-efficient equipment designed to produce two different profiles on a single machine. These machines are particularly valuable for industries like construction, where varying profiles are essential for projects such as roofing and cladding. In Canada, the demand for these machines has been increasing due to their versatility and efficiency.

A double deck roll forming machine combines two profile production lines into a single unit, allowing users to switch between profiles without the need for additional equipment. The machine is widely used for making roofing sheets, wall panels, and cladding materials. It is ideal for companies that need multiple profiles but have limited floor space in their facility.

| Component | Specification |

|---|---|

| Material Thickness | 0.3mm to 0.8mm (customizable) |

| Material Type | Galvanized steel, aluminum, or pre-painted steel |

| Roller Material | High-grade steel with chrome plating |

| Roller Stations | 16–20 stations (depending on profile complexity) |

| Shaft Diameter | 70mm–90mm |

| Forming Speed | 10–15m/min (adjustable based on material) |

| Cutting System | Hydraulic cutting with mold steel blades |

| Motor Power | 7.5 kW main motor + 4 kW hydraulic system |

| Control System | PLC system with touch-screen interface |

| Voltage | Customized for Canada (typically 380V, 60Hz, 3-phase) |

| Dimensions | 8m x 1.5m x 1.2m |

| Weight | 6–8 tons (varies with specifications) |

Double deck machines are typically used to create:

The primary benefits include:

Yes, manufacturers can customize the rollers and specifications to meet Canadian construction standards and preferences.

Typically, the delivery time ranges from 8–12 weeks, depending on the manufacturer and custom requirements.

Many international manufacturers collaborate with local service providers in Canada to offer installation, training, and maintenance services.

Trapezoidal and corrugated profiles are the most commonly used for roofing and cladding applications across Canada.

Modern double deck roll forming machines are equipped with energy-efficient motors and PLC systems, ensuring low power consumption without compromising performance.

Yes, these machines are built to operate efficiently in varying temperatures, with options for cold-weather enhancements.

A double deck roll forming machine is an excellent investment for Canadian businesses looking to optimize space, reduce costs, and increase production versatility. With customization options, reliable performance, and adaptability to local standards, this machine is a valuable asset for roofing and cladding industries across the country.

Copyright 2026 © Machine Matcher.