To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

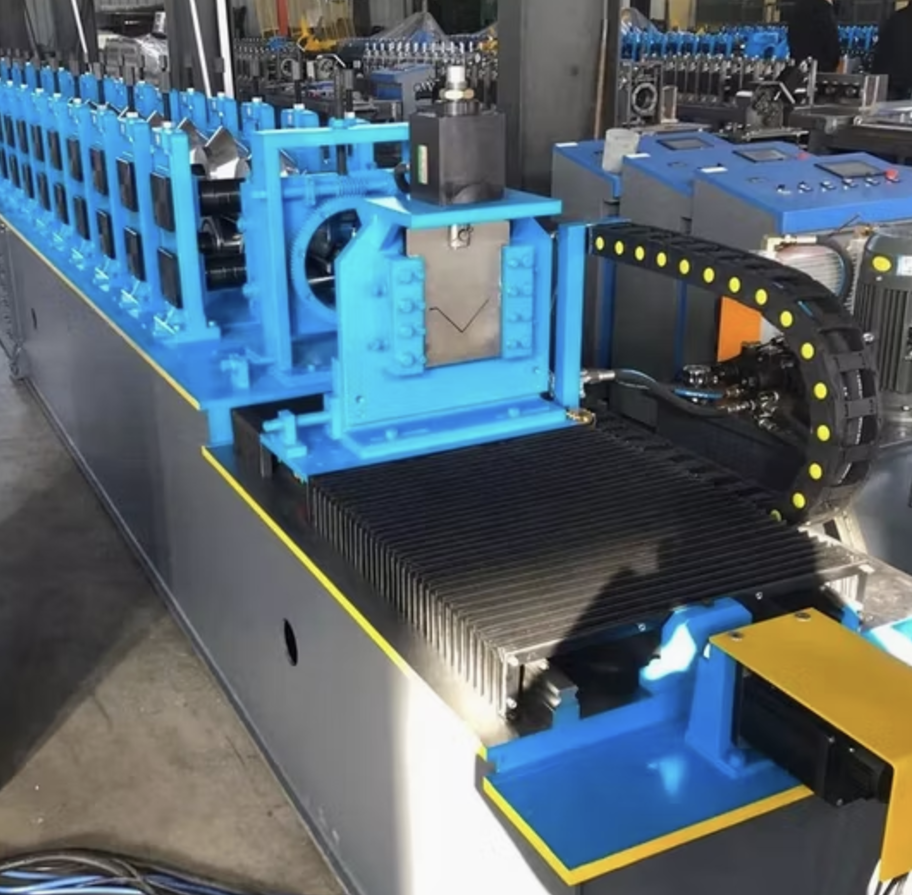

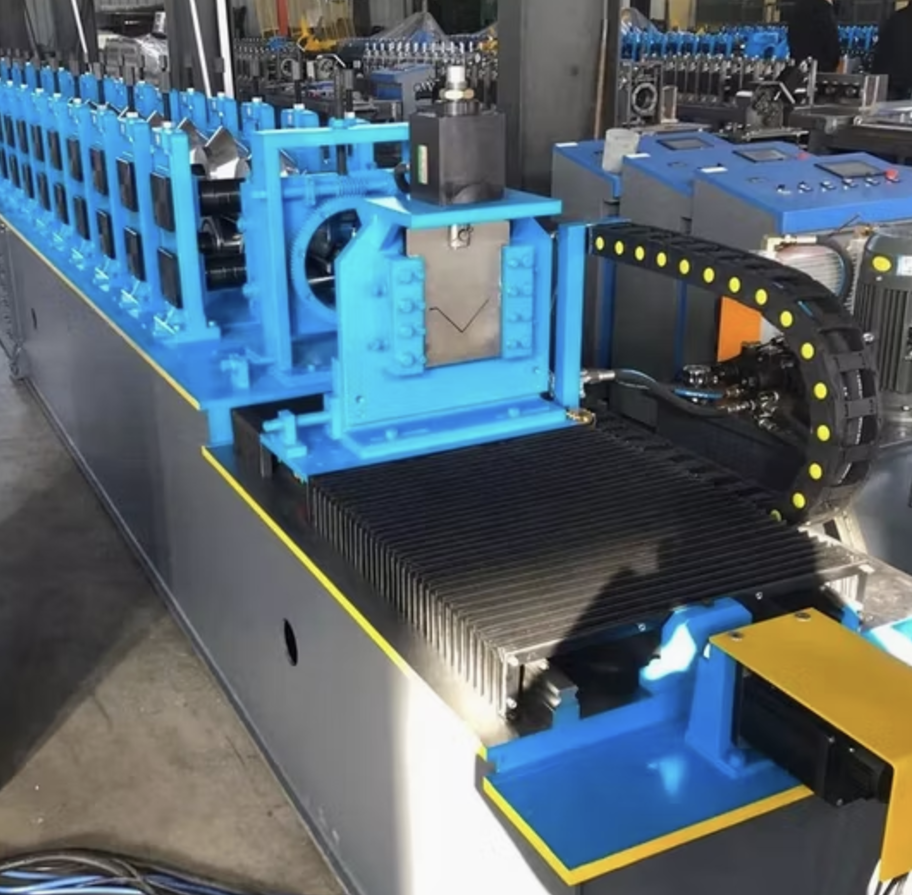

Drip edge roll forming machines are specialized equipment designed to manufacture drip edge profiles, commonly used in roofing systems to channel water away from fascia and protect the underlying structure. These machines are pivotal for producing precision-engineered drip edges that meet the high standards of modern roofing systems.

In Brazil, with its diverse climate and thriving construction sector, drip edge roll forming machines are indispensable tools for manufacturers catering to residential, commercial, and industrial projects.

A drip edge roll forming machine automates the production of drip edge profiles by shaping flat metal sheets into precise edge designs. These machines are known for their durability, efficiency, and ability to handle a variety of materials, including aluminum, galvanized steel, and coated steel.

| Parameter | Details |

|---|---|

| Material Thickness | 0.3 mm – 1.2 mm |

| Material Width | Up to 600 mm |

| Roller Material | GCr15 with chrome plating |

| Frame | 350 H steel frame |

| Drive System | Chain or gearbox |

| Motor Power | 5.5 kW – 15 kW |

| Machine Speed | 10 m/min – 30 m/min |

| Cutting System | Hydraulic cutting with hardened steel blades |

| Control System | PLC control with touchscreen (brands like Siemens) |

| Dimension | Approx. 7m x 1.5m x 1.2m (varies by model) |

| Weight | 4,000 kg – 6,000 kg |

Drip edge profiles produced by these machines include:

Q1. What materials can a drip edge roll forming machine in Brazil process?

A1. The machine can process materials like aluminum, galvanized steel, and coated steel, with thicknesses ranging from 0.3 mm to 1.2 mm.

Q2. How fast can the machine produce drip edge profiles?

A2. Most machines operate at speeds of 10 m/min to 30 m/min, depending on the material and profile complexity.

Q3. Is it easy to change the profile design?

A3. Yes, the machine is designed for flexibility, allowing easy adjustments or tooling changes to produce various drip edge designs.

Q4. How does this machine cater to the Brazilian market?

A4. With its capability to produce profiles suitable for diverse climatic conditions and roofing styles, the machine supports Brazil’s expanding construction and roofing needs.

Q5. What are the power requirements?

A5. Most machines require a 380V, 50Hz power supply, commonly available in industrial setups across Brazil.

Q6. Can I get after-sales service and support in Brazil?

A6. Many suppliers offer local service centers or remote assistance for machine maintenance and troubleshooting in Brazil.

Q7. How much does a drip edge roll forming machine cost in Brazil?

A7. Prices range from $25,000 to $80,000, depending on features, production speed, and customization.

Copyright 2026 © Machine Matcher.