To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

|

Material |

Steel Coil |

|

Thickness |

0.5-1.6mm |

|

Transmission |

Chain/Gear/Gearbox |

|

Speed |

10-15m/min |

|

Roller |

Steel with quenched treatment,chromed on the surface |

|

Shaft |

steel with tempering treatment |

|

Cutting type |

Hydraulic cutting |

|

Cutting material |

Cr12 with quenched treatment Hardness58°-62° |

|

Welding |

Automatic spot welding |

|

Control system |

PLC |

|

Electric brand |

Delta,Siemens,Schneide |

|

Voltage |

380V,50HZ,3PH(or as customers' request) |

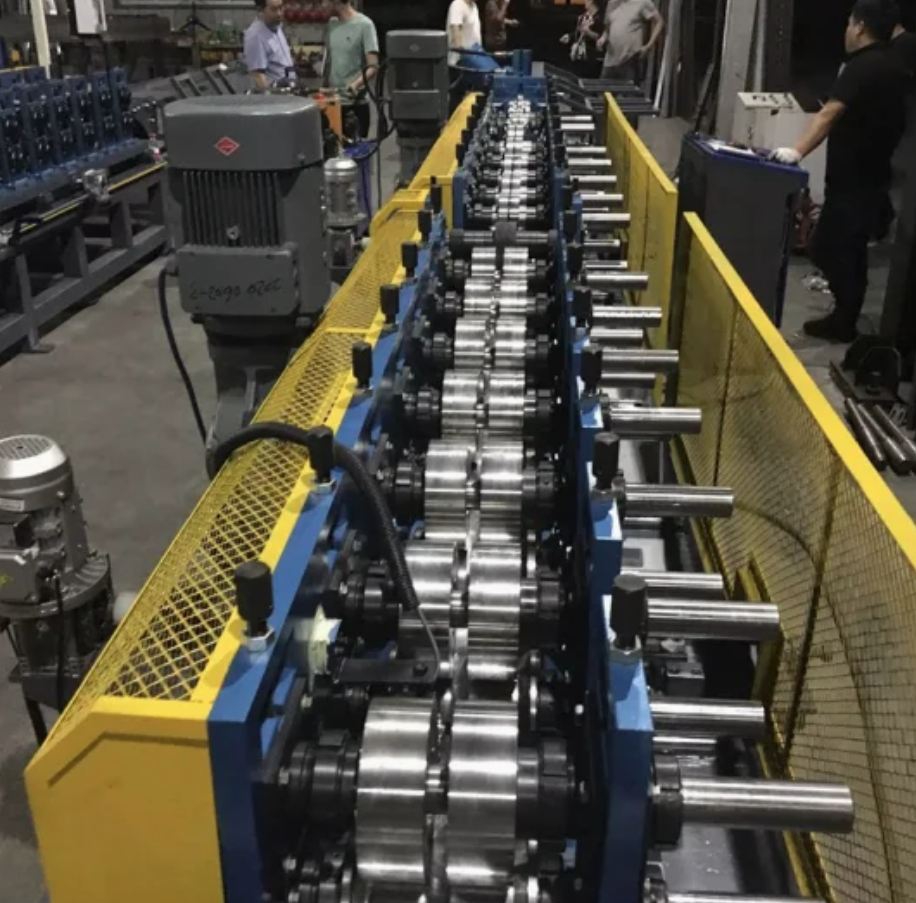

A drywall roll forming machine is designed to produce components used in drywall construction, such as metal studs, tracks, and channels, which serve as framing structures for walls and ceilings. These machines transform coiled sheet metal (usually steel or aluminum) into precise profiles through a continuous bending operation.

Key features typically include:

Copyright 2026 © Machine Matcher.