To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

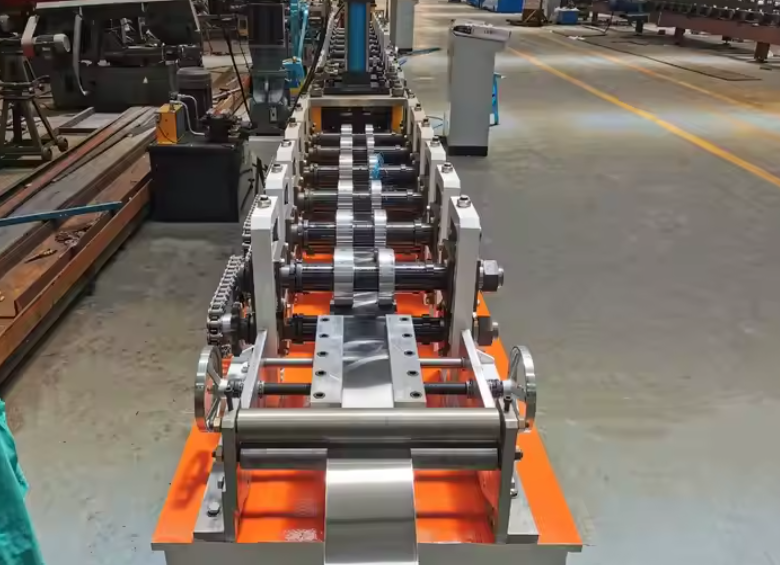

End Wall Flashing Roll Forming Machine – United Arab Emirates

Overview

The End Wall Flashing Roll Forming Machine is engineered to produce precision-formed end wall flashing components for metal roofing systems commonly used across industrial, commercial, and residential buildings in the UAE. Designed for continuous, high-speed, and automated production, this roll forming system delivers consistent output with clean finishes, tight tolerances, and minimal waste.

Specifically suited for the UAE’s booming construction and roofing industries—including areas such as Abu Dhabi, Dubai, and Sharjah—this machine is ideal for manufacturers supplying flashing products for metal building systems, steel warehouses, prefabricated structures, and architectural roofing solutions.

Whether installed in a standalone factory or integrated into a full metal roofing panel production line, this end wall flashing machine meets the region’s demand for fast lead times, corrosion-resistant materials, and profile precision. Each machine is custom-built to the customer’s specifications and is backed by full warranty and support.

Machine Technical Specifications

Machine Type: End Wall Flashing Roll Forming Machine

Production Speed: 10–25 meters per minute (adjustable based on material and profile)

Material Thickness Range: 0.3 mm – 0.8 mm

Material Width Range: 200 mm – 600 mm (depending on profile width)

Material Types: Galvanized Steel (GI), Pre-painted Galvanized Steel (PPGI), Aluminum, Stainless Steel

Material Yield Strength: Up to 550 MPa

Roller Material: High-grade GCr15 (hardened steel)

Roller Surface Treatment: Hard chrome plated for corrosion resistance and extended life

Number of Forming Stations: 10–18 (depending on profile complexity)

Roller Shaft Diameter: 60 mm

Shaft Material: High-strength 45# steel, precision machined and tempered

Main Drive Type: Gearbox drive with chain or direct coupling

Power (UAE): 380V / 50Hz / 3 Phase

Motor Power: 5.5 kW – 7.5 kW (depending on line configuration)

Cutting Method: Hydraulic post-cut or flying cut system

Blade Material: Cr12MoV (heat-treated and precision ground)

Control Type: PLC-controlled system with touch screen interface

Operating Mode: Fully automatic with manual and jog functions

De-coiling System: Manual or hydraulic uncoiler (3-ton standard)

Punching/Notching System (if included): Optional hydraulic or servo punching unit before forming

Machine Frame: Welded steel base with heavy-duty structure

Thickness of Frame Steel: 16–20 mm depending on machine size

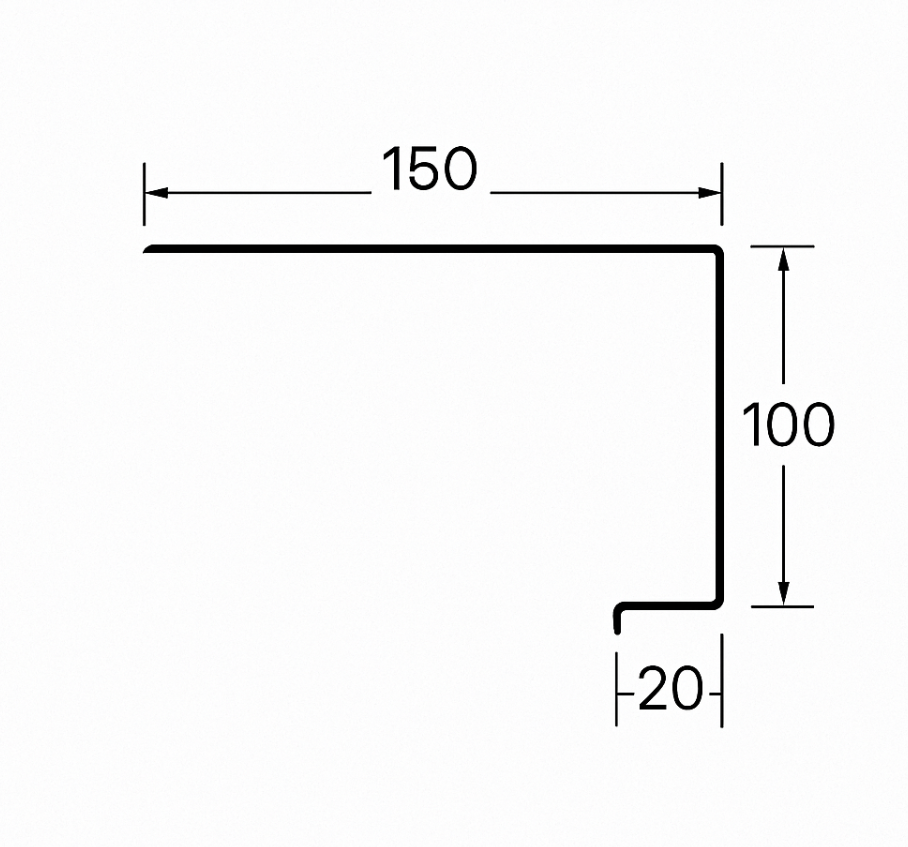

Profile Shape: Custom end wall flashing (typically L or Z-shaped with hem or return folds)

Profile Width and Depth: As per customer drawing – common ranges 100–300 mm width, 20–50 mm return folds

Length Tolerance: ±1 mm per 3 meters

Safety Features:

Protective Covers/Guards on transmission and cutter

Emergency Stop Button

Overload Protection System on hydraulic and electric units

Pricing

Prices Start From: USD $34,000 (depending on configuration and profile complexity)

What Affects the Final Price:

Required production speed

Profile complexity and forming stations

Material range and width

Inclusion of punching or notching systems

Automation level and control system brand

Optional extras such as hydraulic uncoilers, automatic stackers, or coil handling equipment

Contact us to receive a precise quote tailored to your specifications, project requirements, and location in the UAE.

Industry Applications in the UAE

This roll forming machine is ideal for fabricators, steel building manufacturers, and metal roofing companies producing:

End wall flashing for steel warehouses and factories

Trim pieces for residential metal roofing

Finishing profiles for commercial retail structures

Water-resistant edge protection in prefab and modular buildings

Flashing systems used in industrial rooftops for wind and water sealing

Industries served include:

✔ Metal roofing and cladding

✔ Steel building fabrication

✔ Modular construction

✔ Infrastructure projects

✔ Industrial sheds and warehouses

Delivery & Warranty (UAE)

All machines are new and custom-built to meet your exact profile and capacity requirements. Machines are delivered directly to any location across the United Arab Emirates—including Abu Dhabi, Dubai, Sharjah, and other cities—via our trusted logistics network.

Warranty: 1 year from dispatch

Support: Ongoing maintenance, technical advice, and parts availability

Send Your Profile for Quotation

If you have profile drawings or material details, please email them to:

[email protected]

We will prepare a fully customized offer based on your production needs.

Frequently Asked Questions (FAQs)

Q1: What is end wall flashing used for in UAE buildings?

A: End wall flashing is a metal profile used to seal the joint where the end of a roof meets a wall, preventing rainwater or dust ingress. It’s essential for both aesthetics and weatherproofing in metal-clad buildings.

Q2: Can I run aluminum or stainless steel through this machine?

A: Yes. This machine is capable of forming a range of materials including aluminum, stainless steel, and PPGI/GI with a yield strength up to 550 MPa.

Q3: How long does delivery take to the UAE?

A: Average delivery is 8–12 weeks after deposit confirmation. We handle international shipping directly to your site.

Q4: What optional upgrades are available?

A: Optional upgrades include automatic stackers, servo punching units, remote PLC diagnostics, and coil car tippers.

Q5: Do I need a technician to install it?

A: We provide remote installation guidance or can arrange on-site installation and training within the UAE.

Q6: How do I get a quote?

A: Simply send us your required profile sketch, material thickness, and expected output. Our team will match you with the best solution and pricing.

Machine Matcher – Your Trusted Machinery Partner in the UAE

Machine Matcher is proud to deliver reliable, factory-direct metal forming solutions tailored to your regional requirements. We ensure each end wall flashing roll forming machine is purpose-built to withstand UAE climate conditions and industry demands.

Let us match you with the right machine – every time.

[email protected]

All machines are new, custom-built, and globally supported.

Copyright 2026 © Machine Matcher.