To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

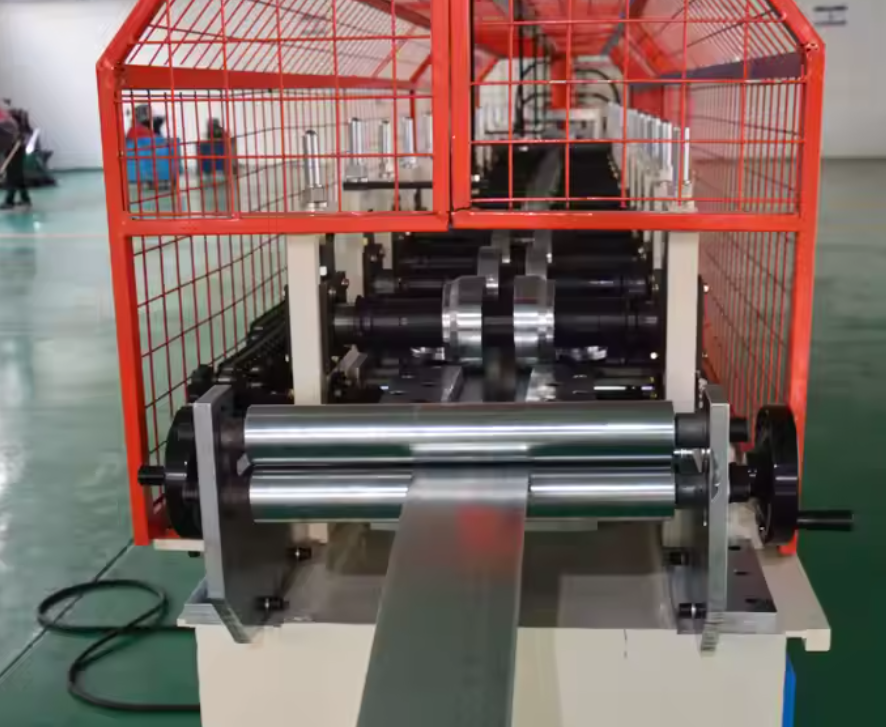

F-Channel Roll Forming Machine – Built for Precision and Performance in the UAE

The F-Channel roll forming machine is a high-precision solution engineered for the efficient production of F-channel profiles, commonly used in ceiling systems, wall panel edge trims, and drywall framing. Designed for continuous and high-speed manufacturing, this machine is ideal for UAE-based construction, interior fit-out, and drywall supply industries that demand quality, reliability, and volume production.

Whether you’re operating in Abu Dhabi, Dubai, Sharjah, or anywhere across the UAE, this machine is custom-built to suit your specific F-channel profile needs and is ready for delivery directly from our trusted global manufacturing partners.

Custom-Built for UAE Construction Needs – Tailored to meet hot-climate operating conditions and common profile standards in the UAE market.

High Speed and Precision – Production speeds up to 40m/min ensure faster turnaround and higher throughput.

Robust, Industrial-Grade Components – Built with high-grade steel frame and hardened rollers for durability in continuous operation.

Flexible Material Handling – Supports a wide range of galvanized steel, aluminum, and pre-painted steel.

Energy-Efficient Motor Systems – Designed to match UAE power supply standards, optimizing energy usage and reducing operational costs.

One-Year Warranty & Maintenance Support – Every machine includes a full year of warranty and expert after-sales assistance.

Machine Type: F-Channel Roll Forming Machine (Cold Forming)

Production Speed: Up to 40 meters per minute

Material Thickness Range: 0.3 mm – 0.8 mm

Material Width Range: 80 mm – 250 mm (customizable)

Material Types: Galvanized Steel, Galvalume, Aluminum, Pre-painted Steel

Material Yield Strength: Up to 550 MPa (80 ksi)

Roller Material: GCr15 (High-Grade Chromium Steel)

Roller Surface Treatment: Hard Chrome Plated for Anti-Corrosion

Number of Forming Stations: 12–16 stations (based on profile complexity)

Roller Shaft Diameter: 40 mm – 60 mm

Shaft Material: High-Strength 45# Steel, Heat-Treated

Main Drive Type: Chain Drive or Gearbox Drive (customizable)

Power (UAE): 380V / 50Hz / 3-Phase

Motor Power: 4–5.5 kW (depending on configuration)

Cutting Method: Hydraulic Cutting with Sensor-Triggered Stop

Blade Material: Cr12MoV (Heat-Treated)

Control Type: PLC Control System with HMI Touch Screen

Operating Mode: Fully Automatic

De-coiling System: Manual or Hydraulic De-coiler (3–5 Ton Optional)

Punching/Notching System: Optional Hydraulic Punching Unit

Machine Frame: Welded Structural Steel Frame, CNC-Machined

Thickness of Frame Steel: 16 mm

Profile Shape: F-Channel

Profile Width and Depth: Width: 20–50 mm, Depth: 10–30 mm (customizable)

Length Tolerance: ±1 mm per 6 m

Safety Features:

Protective Covers/Guards

Emergency Stop Buttons

Overload Protection System

Drywall & Ceiling Systems

Interior Fit-Out Contractors

Commercial and Residential Construction

Partition Framing Manufacturers

Industrial Building Fitters

Example Uses:

In UAE construction, F-channels are essential in false ceiling installations, drywall partition systems, wall panel edge trims, and HVAC duct support. This machine enables manufacturers to meet bulk project timelines with precision and quality assurance.

Galvanized Steel: 0.4–0.6 mm | 40–55 ksi

Aluminum: 0.5–0.8 mm | 25–30 ksi

Pre-painted Steel: 0.4–0.6 mm | 40–50 ksi

These materials are widely available in the UAE and supported by local coil suppliers.

Starting Price: $36,000 - USD (Standard Configuration)

What Affects the Final Price:

Number of forming stations

Material width and profile complexity

Punching or notching additions

Type of decoiler (manual or hydraulic)

Automation and stacker systems

Electrical customization (if outside standard UAE voltage)

For the most accurate and cost-effective quote, we recommend sending your profile drawing, material gauge, and coil width to:

[email protected]

Adjustable Roll Tooling for Multiple F-Channel Sizes

Hydraulic Punching System for Screw Holes or Cutouts

Servo Motor Drive for Higher Speed Accuracy

Inline Stacker or Run-Out Table

Remote Control PLC Monitoring

Coil Car for Easy Coil Handling

Dual Profile Setup (for F-Channel and Shadow Line)

All machines are new, built-to-order, and shipped from our trusted manufacturing partners. We offer full delivery across the UAE including:

Dubai

Abu Dhabi

Sharjah

Ajman

Ras Al Khaimah

1-Year Warranty from the date of dispatch

Durable Maintenance and Repair Support

Expert Help: [email protected]

Q: Can this machine make multiple sizes of F-channels?

A: Yes, with adjustable tooling or replaceable rollers, it can accommodate multiple sizes if specified during order.

Q: Is the machine compatible with UAE electrical standards?

A: Yes, all machines for the UAE market are configured for 380V / 50Hz / 3-phase operation.

Q: Do I need a hydraulic decoiler for this machine?

A: For medium to large batch production, a hydraulic decoiler (3–5 tons) is recommended for faster setup and operation.

Q: What support do I get after purchasing?

A: You receive full machine manuals, online setup guidance, spare parts availability, and one year of warranty coverage.

Q: How long is the production and delivery time?

A: Standard production time is 30–45 days, with delivery arranged directly to your UAE address.

To get started with your custom F-Channel roll forming machine, contact us with your profile drawing and project details at:

[email protected]

Machine Matcher – Delivering precision roll forming machines to the UAE and beyond.

Copyright 2026 © Machine Matcher.