To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

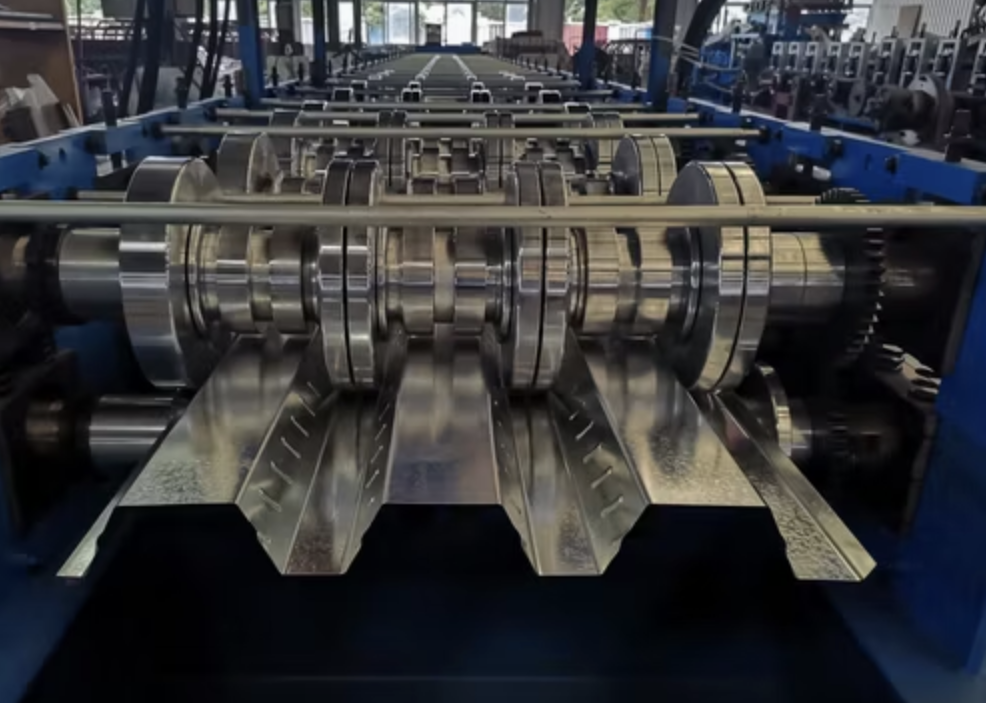

A Floor Deck Roll Forming Machine is a specialized industrial machine designed to produce high-strength floor decking panels commonly used in construction projects, especially for multi-story buildings and roofing solutions. Floor decking panels are structural components that provide enhanced load-bearing capacity and can be used as permanent frameworks in concrete structures. This machine plays a vital role in manufacturing these components with high precision, speed, and consistency.

The Floor Deck Roll Forming Machine is designed to produce corrugated or ribbed floor deck profiles that serve as formwork and reinforcement in concrete slabs. These machines are typically heavy-duty and can handle a variety of materials, thicknesses, and sizes according to construction requirements.

The process starts with a coil of steel that feeds through the machine. The steel is then pressed and formed by a series of precisely arranged rollers, which shape the material into the desired profile. Once formed, the decking profile is cut to length with a hydraulic cutting system, ensuring clean edges and precise dimensions. The entire process is controlled by a PLC (Programmable Logic Controller) system, allowing for high automation, consistent quality, and ease of operation.

Floor deck profiles are predominantly used in:

Q1: What materials can the Floor Deck Roll Forming Machine handle?

A1: The machine is primarily designed for steel coils, typically galvanized steel, as it provides excellent strength and durability for floor deck panels. Other materials such as aluminum or stainless steel can also be used depending on the application and machine specifications.

Q2: How fast can the machine produce floor deck panels?

A2: Production speeds can vary but typically range between 10-15 meters per minute, depending on the profile complexity, material thickness, and machine model.

Q3: Is the machine suitable for various deck profiles?

A3: Yes, Floor Deck Roll Forming Machines can be customized to produce different deck profiles. The rollers can be adjusted or changed to create different rib patterns and depths, based on the project's structural requirements.

Q4: How does the machine ensure profile accuracy?

A4: Accuracy is achieved through precision-engineered rollers and an advanced PLC system, which controls every aspect of the forming process, from feed rate to cutting length. This high degree of automation ensures consistent and accurate output with minimal variation.

Q5: Can the machine be integrated with other production systems?

A5: Yes, many Floor Deck Roll Forming Machines offer integration with other systems, such as uncoilers, stackers, and automated material handling systems, to create a seamless production line.

Q6: What maintenance is required for a Floor Deck Roll Forming Machine?

A6: Regular maintenance includes lubrication of moving parts, inspection of the rollers and cutting system, and checking electrical systems. Periodic calibration is also recommended to maintain precision, especially after prolonged use.

Q7: Can one machine produce multiple floor deck sizes?

A7: Many machines allow adjustments for different profile widths and thicknesses. However, more significant changes in deck profile designs may require a roller change, which can typically be done with modular systems or by ordering custom roller sets.

This versatile and efficient machine is a critical asset for any construction materials production line, offering precision and durability for long-term projects.

Copyright 2026 © Machine Matcher.