To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

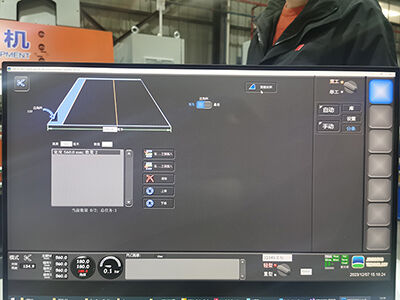

JSZW1000 intelligent double bending machine is specially designed for the metal sheet processing industry. With bending fully automated in both directions, it is suitable for bending and processing various components such as ridges, eaves, door openings, window openings, platforms, etc. in steel structure buildings, as well as edging and cornering of various components. It can also be used for bending and processing of metal sheets in other industries.

Technical Parameters

Technical Parameters

| Item | Parameter |

| Max. bending length | 10 m |

| Throat depth | 1220 mm |

| Number of folding units | 8 |

| Number of rear clamping units | 11 |

| Equipment power | 33 kW |

| Hydraulic power | 2×15 kW |

| Power supply | AC380V/50Hz |

| Working temperature | +5℃~+45℃ |

| Max. hydraulic pressure | 14 MPa |

| Hydraulic clamping | Light load: 8 MPa Heavy load: 12 MPa |

| Maximum folding angle | 150° |

| Max. support distance | 1220 mm |

| Min. support distance | 10 mm |

| Minimum rear clamp feeding distance | Clamping: 15 mm Pushing: 10 mm |

| Rear clamp feeding speed | Max. 200 mm/s |

| Air pressure | 0.6 MPa |

| Bending speed | 6 s |

| Clamping speed | 150 mm/s |

| Cutting speed | 17 s |

| Longitudinal cutter fixture offset | 48 mm |

| Weight | 23 T |

| Overall dimensions (L×W×H) | 11700×2120×1975mm |

Copyright 2026 © Machine Matcher.