To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

High-Quality, Custom-Built Solutions for Roofing and Cladding Projects Across the UAE

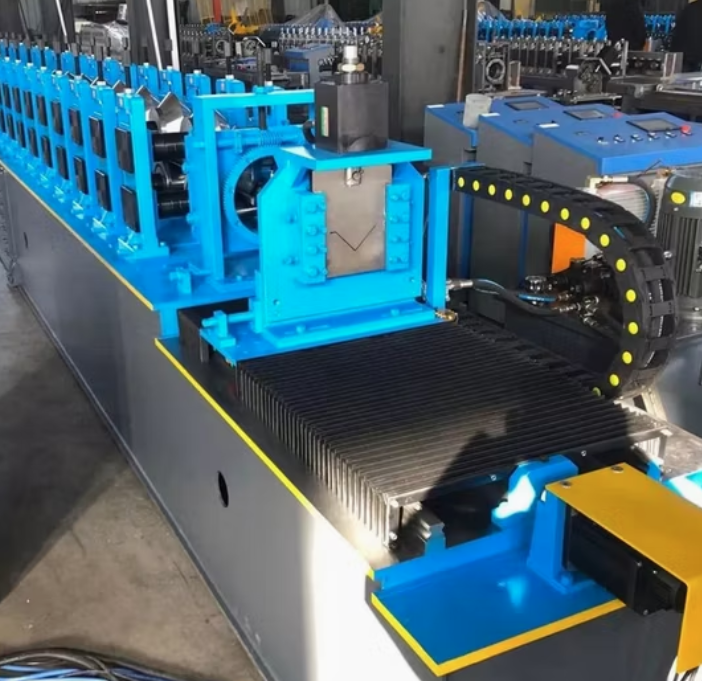

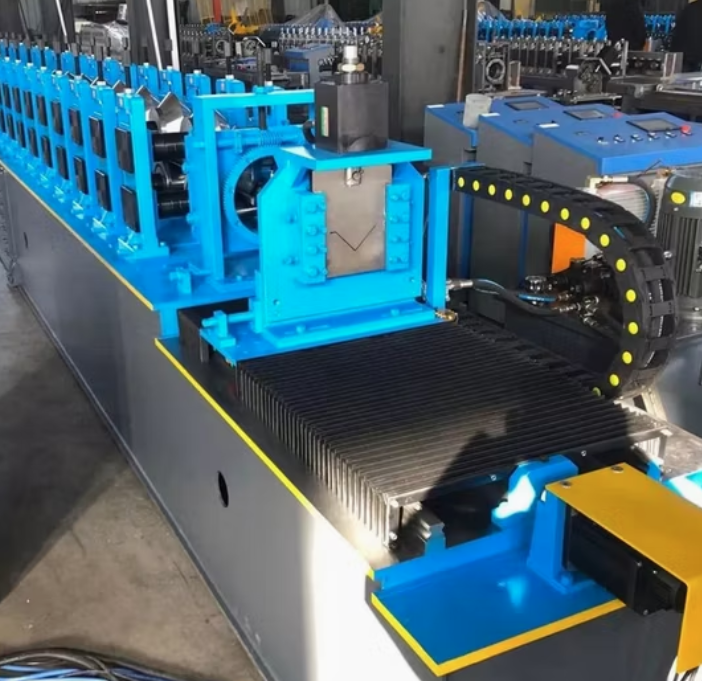

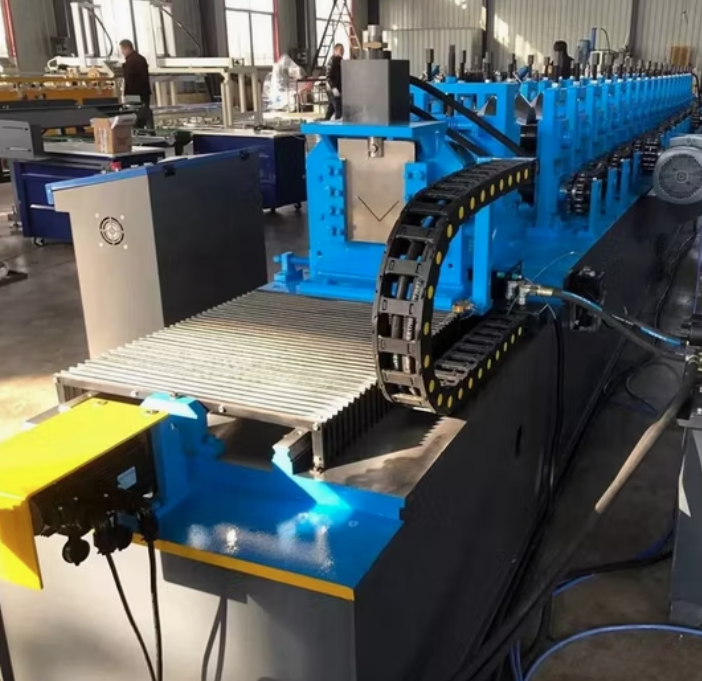

Machine Matcher proudly offers a Gable Flashing Metal Roof Roll Forming Machine, specifically designed for customers across the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and beyond. This machine is engineered to deliver precise, efficient, and durable production of gable flashing profiles, vital components for metal roofing systems in commercial, industrial, and residential construction projects.

All our machines are new and custom-built based on the specific gable flashing profiles, materials, and production needs of each customer. Whether you're setting up a new roofing production line or expanding your capabilities, we supply machines designed for the UAE market’s high standards and climate conditions.

| Specification | Details |

|---|---|

| Machine Type | Gable Flashing Metal Roof Roll Forming Machine |

| Production Speed | 10–15 meters/min (adjustable based on profile and material) |

| Material Thickness Range | 0.3mm–0.8mm |

| Material Width Range | Up to 600mm (customizable) |

| Material Types | Galvanized Steel, Galvalume, Aluminum, Color-Coated Steel |

| Material Yield Strength | Up to 350 MPa |

| Roller Material | High-Grade 45# Steel |

| Roller Surface Treatment | Hard Chrome Plated (for anti-rust and smooth surface finish) |

| Number of Forming Stations | 12–18 stations (depending on profile) |

| Roller Shaft Diameter | 70mm |

| Shaft Material | 45# High-Strength Steel, precision-ground |

| Main Drive Type | Gearbox Drive (ensures stable, synchronized operation) |

| Motor Power | 7.5kW (sized for UAE 3-phase 380V/50Hz power supply) |

| Cutting Method | Hydraulic Cutting (cutting after forming for high precision) |

| Blade Material | Cr12Mov (heat-treated, high-strength cutting blade) |

| Control Type | PLC Control System (brands such as Siemens, Delta, or Schneider) |

| Operating Mode | Automatic and Manual operation modes |

| De-coiling System | Manual or Hydraulic De-coiler options available (3–5 Ton capacity) |

| Punching/Notching System (if included) | Optional hydraulic punching station (customizable) |

| Machine Frame | Welded Steel Structure, precision-machined |

| Thickness of Frame Steel | 20mm |

| Profile Shape | Custom Gable Flashing Profile (to customer’s drawings) |

| Profile Width and Depth | As per customer specifications |

| Length Tolerance | ±1.5mm |

| Safety Features | Full suite of protections for safe operation |

| - Protective Covers/Guards | Installed over moving parts |

| - Emergency Stop Button | Standard, easily accessible |

| - Overload Protection System | Integrated in control system to protect motor and hydraulic systems |

The Gable Flashing Metal Roof Roll Forming Machine is essential for companies operating in:

Construction and Roofing Projects

Steel Fabrication Industries

Metal Building Systems

Commercial, Industrial, and Residential Construction

Roofing and Cladding Manufacturers

In the UAE, where both modern architectural projects and durable infrastructure are in high demand, gable flashing is crucial for providing a professional and waterproof edge to metal roof systems. This machine helps local companies produce high-quality gable flashing, supporting both large-scale developments and customized small projects.

Location: All machines are delivered anywhere in the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, and surrounding cities.

Delivery: Direct shipment from our trusted manufacturing partner.

Warranty: All machines include a 1-year warranty from dispatch.

Support: Long-term maintenance and repair support is available.

Pricing is based on your specific requirements, such as profile size, material types, speed needs, punching options, and additional automation features.

Contact us for a tailored quote that meets your project specifications.

If you have profile drawings, material specifications, or other requirements ready, please email them to:

[email protected]

A: Yes. The machine is capable of processing galvanized steel, galvalume, aluminum, and color-coated steel materials commonly used for metal roofing in the UAE.

A: Absolutely. We build the machine to match your profile drawings and size requirements.

A: Typical lead time is 8–12 weeks from order confirmation, depending on customization. Delivery within the UAE is arranged immediately after manufacturing.

A: We offer a manual or hydraulic de-coiler based on your production needs. It’s an optional extra that can be included in your quote.

A: We use high-quality, internationally recognized PLC brands such as Siemens, Delta, or Schneider to ensure reliability and easy maintenance.

A: Regular lubrication, cleaning of rollers, checking hydraulic oil levels, and ensuring that electrical systems are in good condition will keep your machine running smoothly.

New, Custom-Built Machines tailored to your project needs.

Global and Local Support – with delivery services across the UAE.

Durable, High-Performance Equipment built for long-term production.

Professional After-Sales Service with spare parts and maintenance support.

Flexible, Competitive Pricing customized for your project requirements.

Copyright 2026 © Machine Matcher.