To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Gable Flashing Metal Roof Roll Forming Machine – UAE Edition

Location: United Arab Emirates (Abu Dhabi, Dubai, Sharjah & nationwide)

Brand: Machine Matcher – Custom-built, Global Delivery

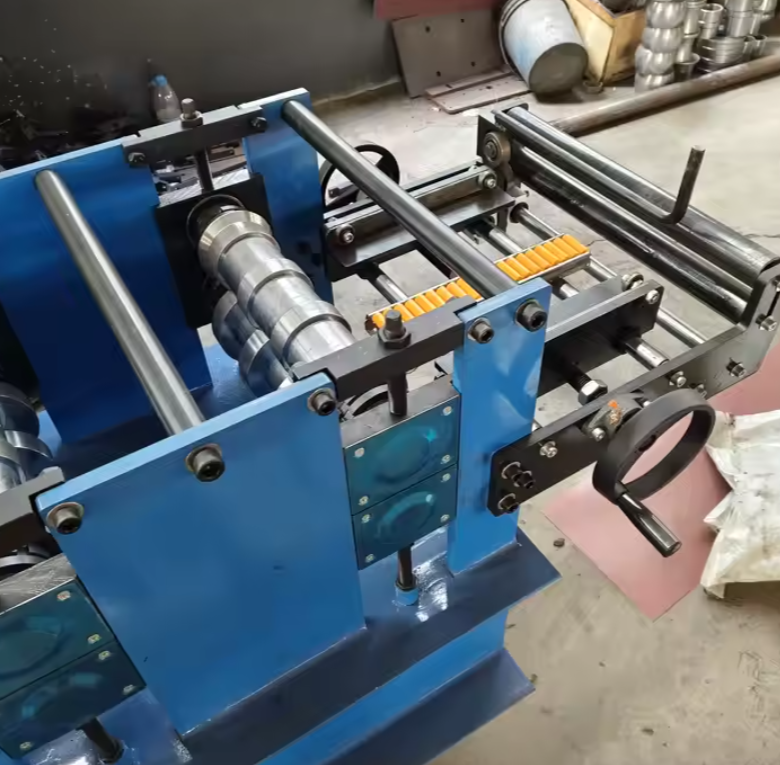

The Gable Flashing Metal Roof Roll Forming Machine is a high-performance solution engineered for producing precision-formed gable flashing profiles used in residential, commercial, and industrial roofing systems. Designed to operate efficiently in the UAE’s high-demand construction and metal roofing sectors, this machine delivers consistent profile quality, fast production speeds, and long-lasting durability—even in hot and arid environments.

The gable flashing profile plays a crucial role in metal roofing by sealing and finishing the edges of pitched roofs, protecting the roof structure from water ingress, wind, and debris. This machine offers automatic forming and cutting, high accuracy, and minimal material waste—ideal for UAE-based fabricators, roofing contractors, and steel building manufacturers.

Machine Type: Gable Flashing Roll Forming Machine

Production Speed: 10–20 meters/min (adjustable depending on material & profile complexity)

Material Thickness Range: 0.3 mm to 0.8 mm

Material Width Range: 150 mm to 600 mm (customizable based on profile)

Material Types: Galvanized steel, pre-painted steel, aluminum, galvalume

Material Yield Strength: Up to 550 MPa (suitable for high-strength roofing materials)

Roller Material: High-grade GCr15 (heat-treated and hardened)

Roller Surface Treatment: Chrome-plated for corrosion resistance and smooth finish

Number of Forming Stations: 12–18 stations (depending on profile shape)

Roller Shaft Diameter: 60 mm

Shaft Material: 45# high-tensile steel (tempered and polished)

Main Drive Type: Gearbox and chain drive (robust and low maintenance)

Power (UAE Specification): 380V / 50Hz / 3-Phase

Motor Power: 4–7.5 kW (depending on speed and configuration)

Cutting Method: Hydraulic cutting (synchronized with line speed)

Blade Material: Cr12Mov (hardened steel, heat-treated for durability)

Control Type: PLC control system with touchscreen HMI (brands like Siemens, Delta, or Mitsubishi)

Operating Mode: Fully automatic or manual mode (switchable)

De-coiling System: Manual or hydraulic uncoiler (3-ton or 5-ton capacity options)

Punching/Notching System: Optional, depending on profile complexity

Machine Frame: Welded steel structure, heavy-duty base frame

Thickness of Frame Steel: 18–25 mm

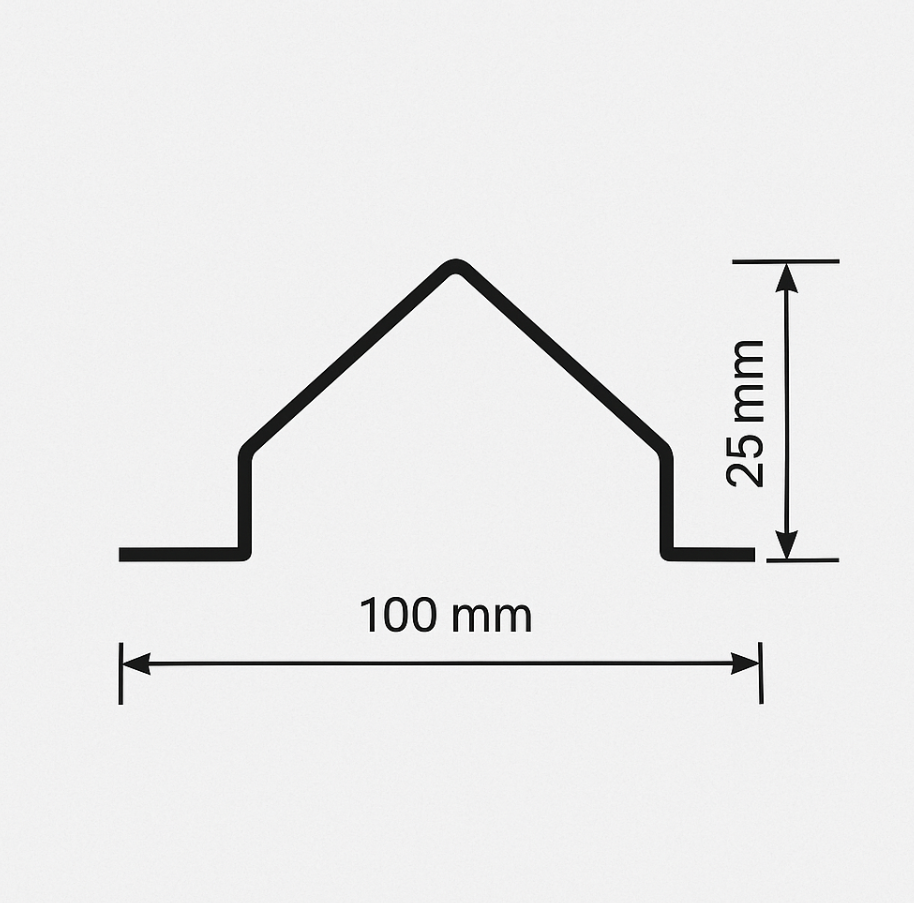

Profile Shape: Gable flashing profile (customizable to national or client standards)

Profile Width and Depth: Typically 100–300 mm wide, 25–100 mm flange height (custom available)

Length Tolerance: ±1.5 mm

Safety Features:

Full protective guards and covers

Emergency stop buttons at key access points

Overload protection and safety limit sensors

This gable flashing roll forming machine is widely used in the following sectors across the UAE:

Steel Roofing & Cladding Installers

Metal Building Manufacturers

Pre-engineered Steel Structures (PEB)

Residential & Commercial Roofing Contractors

Construction & Infrastructure Firms

Roofing Sheet Fabrication Workshops

USD $35,000 (depending on configuration and optional add-ons)

The cost varies based on:

Required profile size and complexity

Material thickness range

Production speed requirements

Optional systems (hydraulic uncoiler, notching, embossing, stacker)

Automation level (fully automatic vs. semi-automatic)

Local voltage or frequency customization

To receive a tailored quote, we recommend submitting:

Profile drawings or sketches

Required sheet thickness and materials

Destination port or delivery city

Preferred machine options (stacker, notching, speed)

Email all relevant information to [email protected]

All gable flashing roll forming machines are new and custom-built to your profile and specifications. Machines are manufactured to order and can be delivered to Abu Dhabi, Dubai, Sharjah, and across the UAE.

Warranty:

1-year warranty from date of dispatch

Remote troubleshooting and support

Optional spare parts packages

On-site installation and training available on request

Q1: Can this machine make multiple flashing profiles?

A: Yes, with interchangeable rollers or adjustable tooling, it can be configured for multiple flashing shapes depending on design.

Q2: How long does delivery to the UAE take?

A: Standard delivery takes 60–90 days depending on production load and shipping. Express manufacturing may be available at additional cost.

Q3: Can you help with installation in the UAE?

A: Yes, Machine Matcher can assist with remote guidance or dispatch a technician for setup and operator training.

Q4: What kind of power supply is needed in the UAE?

A: The machine is built for 380V, 50Hz, 3-phase – the standard in the UAE. Let us know if a different setup is required.

Q5: What’s the minimum order?

A: Just one machine. Each order is custom-made to your profile and material needs.

Q6: Can I add a coil car or automatic stacker?

A: Yes. Optional extras like decoilers, coil cars, stackers, and even automatic packing systems can be added to improve production flow.

To request a quote or send your specifications:

[email protected]

All machines are designed to meet UAE conditions, built to international standards, and supported by a dedicated team with delivery and installation services available.

Let Machine Matcher connect you to the right flashing machine—designed for performance, built for the future.

Copyright 2026 © Machine Matcher.