To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

A garage door roll forming machine is designed to manufacture high-quality garage door panels with precision, efficiency, and speed. These machines cater to the construction and automotive industries, where garage doors play a vital role in both residential and commercial buildings. Garage door roll forming machines streamline the production process, enabling manufacturers to produce a variety of panel designs and sizes to suit different customer needs.

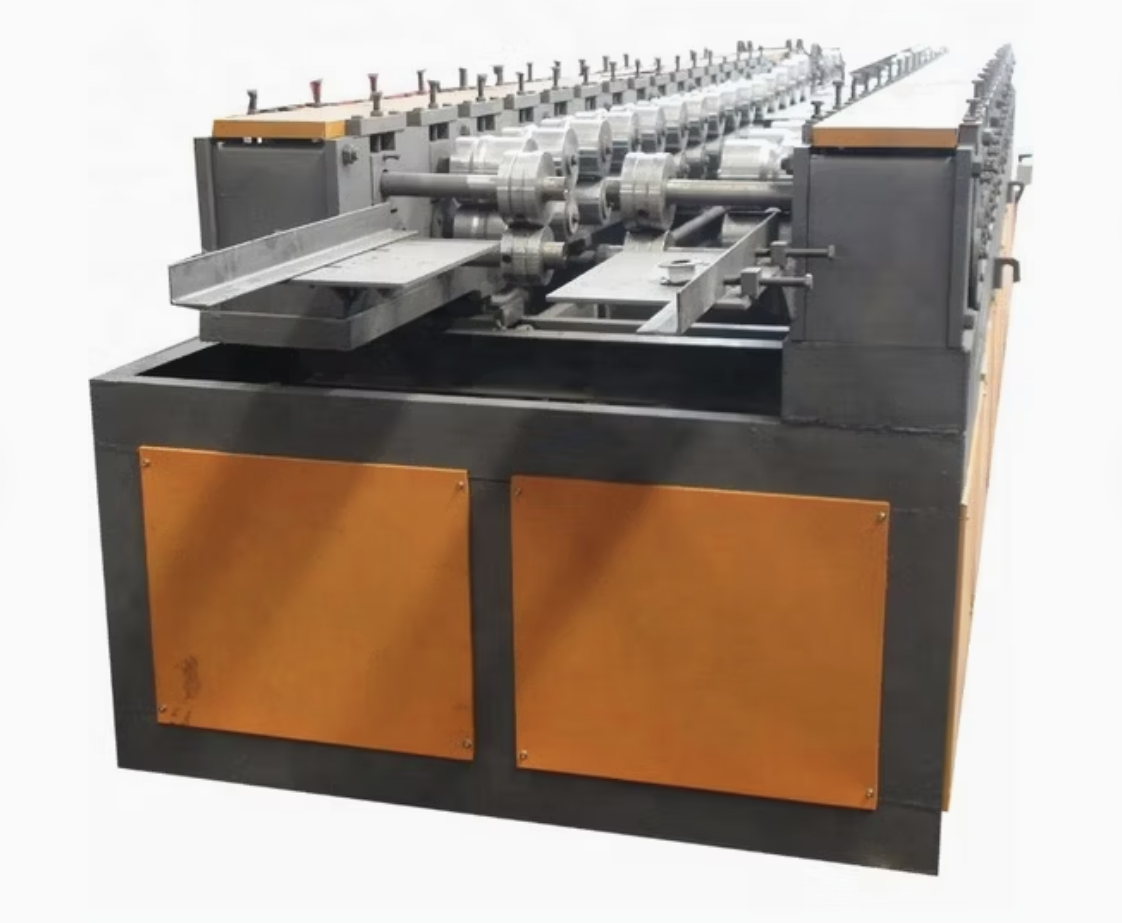

The garage door roll forming machine is a specialized piece of equipment built to produce roll-formed panels used in sectional garage doors. The machine is highly automated, featuring advanced control systems that ensure accuracy and consistency in panel production. Equipped with high-strength rollers and a robust frame, the machine can handle various materials, including galvanized steel, aluminum, and pre-painted steel, making it versatile for different manufacturing requirements.

This machine can be customized to produce panels with unique profiles, such as ribbed, raised, or flush designs, giving flexibility to manufacturers. The automation system in the machine includes programmable logic controllers (PLC) that allow operators to set production parameters, such as length, width, and panel design. Additionally, the machine features an easy setup and changeover process, enabling manufacturers to produce different styles and sizes of garage door panels efficiently.

The setup and installation of a garage door roll forming machine require a flat, stable surface in an industrial space. Once the machine is assembled, it needs to be connected to an appropriate power supply, and operators need to configure the PLC system with the desired panel specifications. The machine requires regular calibration to maintain accuracy and quality in production.

Regular maintenance is crucial for ensuring the longevity and optimal performance of the garage door roll forming machine. Maintenance tasks include lubricating moving parts, inspecting and replacing worn rollers, and checking the alignment of rollers and cutting systems. The PLC system may require periodic software updates to maintain compatibility with the latest manufacturing standards.

Q1: What materials can a garage door roll forming machine handle?

A: Garage door roll forming machines can handle various materials, including galvanized steel, aluminum, and pre-painted steel. The material thickness can range from 0.3 mm to 1.2 mm, depending on the specific machine model.

Q2: Can the machine produce different panel profiles?

A: Yes, most garage door roll forming machines are highly versatile and can produce various panel profiles, including ribbed, raised, and flush designs. Custom profiles can also be produced with specific roller configurations.

Q3: What is the typical production speed of a garage door roll forming machine?

A: Production speeds can vary based on the machine model and material, but most machines operate at 10–15 meters per minute. The speed can often be adjusted to meet different production requirements.

Q4: What safety features are included in these machines?

A: Garage door roll forming machines are equipped with safety guards, emergency stop buttons, and optional enclosures to reduce noise and protect operators from dust. These safety features help create a secure working environment.

Q5: What maintenance does a garage door roll forming machine require?

A: Regular maintenance includes lubricating moving parts, checking for alignment, replacing worn rollers, and cleaning the machine. Periodic inspections of the PLC system and software updates may also be necessary to maintain optimal machine performance.

Q6: How long does it take to set up a new profile?

A: Setup times vary depending on the machine model and the complexity of the profile. However, most modern machines are designed for quick changeovers, allowing operators to switch profiles within 30 to 60 minutes.

Q7: Are there any optional add-ons available for a garage door roll forming machine?

A: Yes, optional add-ons include stackers, uncoilers, recoilers, automatic stackers, remote PLC monitoring systems, and coil handling systems. These extras can help streamline the production process and increase efficiency.

The garage door roll forming machine is a reliable and efficient solution for manufacturing various garage door panels, meeting the needs of both residential and commercial building projects.

Copyright 2026 © Machine Matcher.