To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

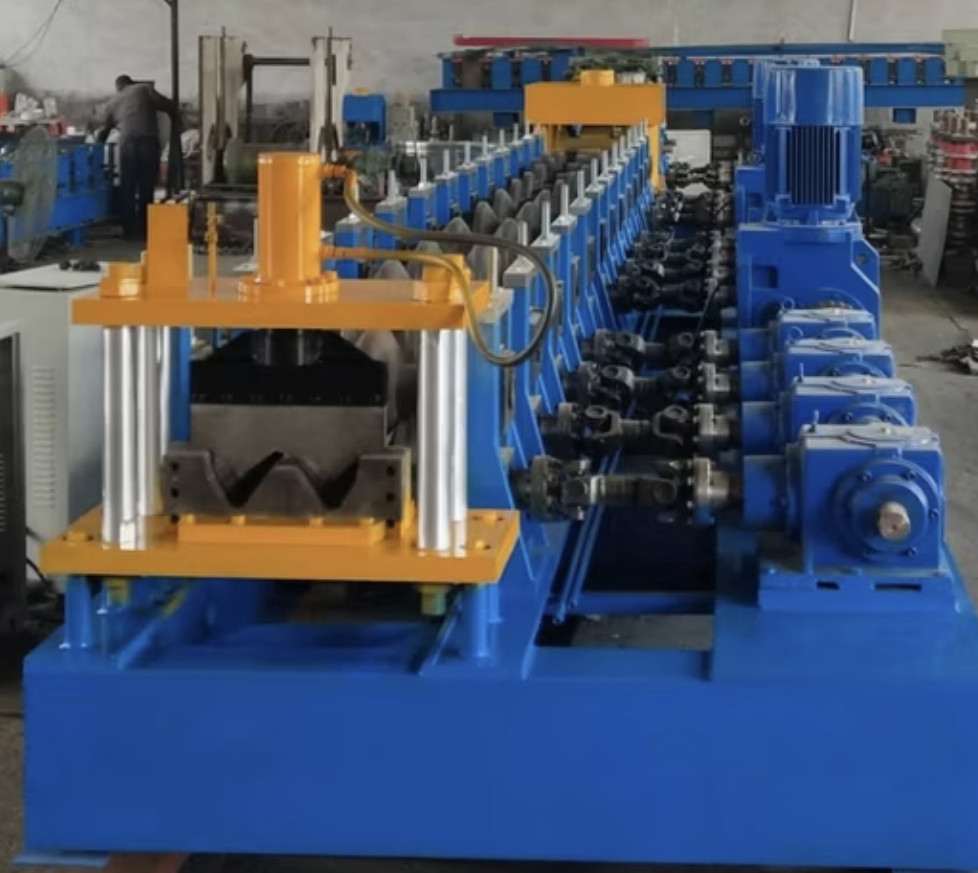

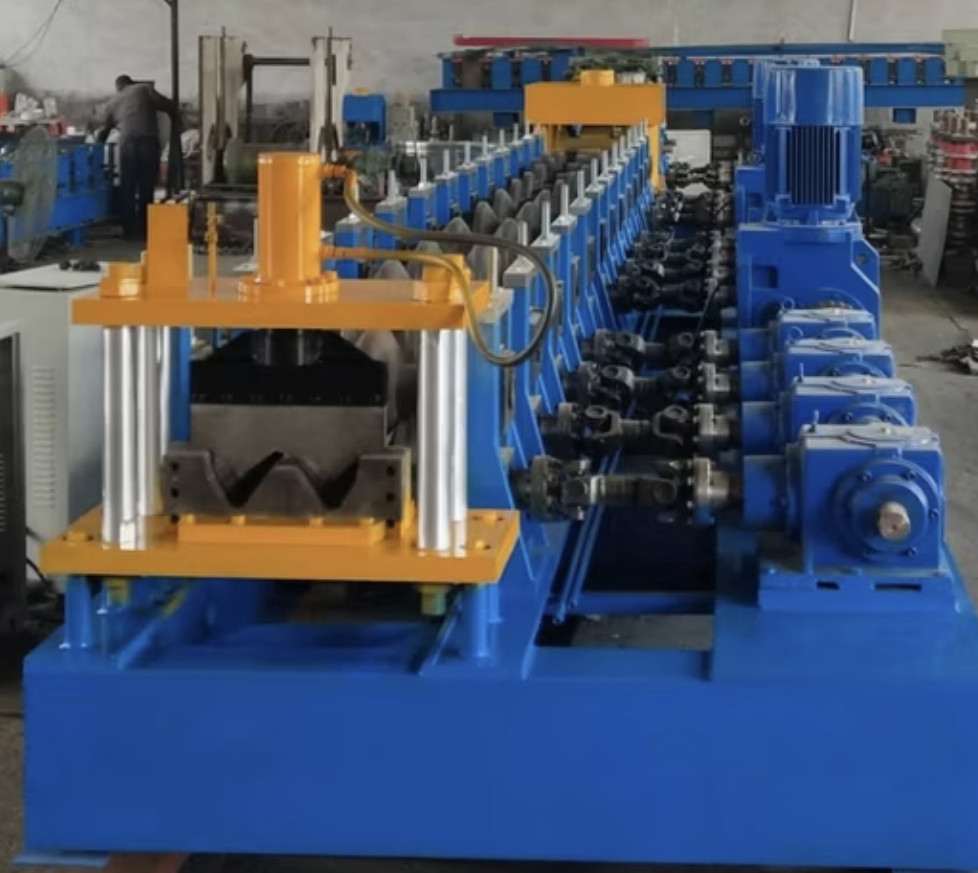

A guardrail roll forming machine is a highly specialized piece of equipment designed for producing highway guardrails, commonly seen on roadsides as a safety barrier for vehicles. These machines are essential in producing high-quality guardrails with consistent accuracy, strength, and durability.

Guardrail roll forming machines create guardrails from coils of steel, which are typically galvanized to prevent rust and corrosion. The machine feeds the metal coil into a series of rollers, gradually forming it into the desired guardrail profile. After forming, the guardrail is often cut to length using a hydraulic cutting system, then punched for bolts and installation holes. This high-precision forming ensures that the guardrails meet stringent safety and quality standards, particularly for use in highway infrastructure.

Here are typical specifications for a guardrail roll forming machine:

Guardrails produced by roll forming machines are made from galvanized or stainless steel to resist corrosion and withstand harsh environmental conditions. The two main types of guardrail profiles are:

Industries and Market Size: Guardrails are widely used in highway safety, parking lots, bridges, and industrial facilities. The primary markets include transportation departments, construction firms, and civil engineering companies.

Setting up a guardrail roll forming machine requires careful calibration and testing to ensure that it meets the specifications for length, width, and hole punching accuracy. A professional installation team often performs initial setup and testing to optimize performance.

Routine maintenance ensures the guardrail roll forming machine continues to operate efficiently and produces high-quality guardrails.

Guardrails are typically made from galvanized steel or stainless steel, as these materials offer high strength and resistance to corrosion, which is essential for outdoor use.

The machine can produce W-beam and Thrie-beam profiles, which are the two most common types of guardrails. W-beams are standard on most highways, while Thrie-beams are used for locations needing extra impact resistance.

The production speed ranges between 10-20 meters per minute, though this may vary depending on the thickness of the steel and the complexity of the guardrail profile.

The hydraulic punching system offers high accuracy, with hole placement accuracy within ±1 mm, ensuring the guardrails meet installation requirements.

Most guardrail roll forming machines require a three-phase power supply, with motor requirements around 15-25 kW depending on the model.

Yes, with an optional remote PLC system, operators can control and monitor the machine’s performance from a remote location, enhancing flexibility and safety.

It’s recommended to perform daily inspections and cleaning, with a comprehensive maintenance check every month or as per the machine’s usage. Regular maintenance extends machine life and ensures consistent product quality.

The machine is equipped with safety guards and enclosures to protect operators. Additionally, emergency stop buttons and automatic shutdown features help prevent accidents.

Yes, guardrail roll forming machines can often be customized based on specific production requirements, such as different profile widths, hole patterns, or additional automated stackers and uncoilers.

The primary markets include transportation departments, road construction companies, and civil engineering firms. The demand for guardrails is particularly high in areas with developing infrastructure and expanding highway networks.

Copyright 2026 © Machine Matcher.