To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Guardrail roll forming machines are essential for producing high-quality, durable highway guardrails. These machines are designed to efficiently create guardrails with precision, ensuring each piece meets the structural requirements for road safety. They are commonly used by companies in the infrastructure and construction industries, particularly for projects involving highways, bridges, and other public transportation routes.

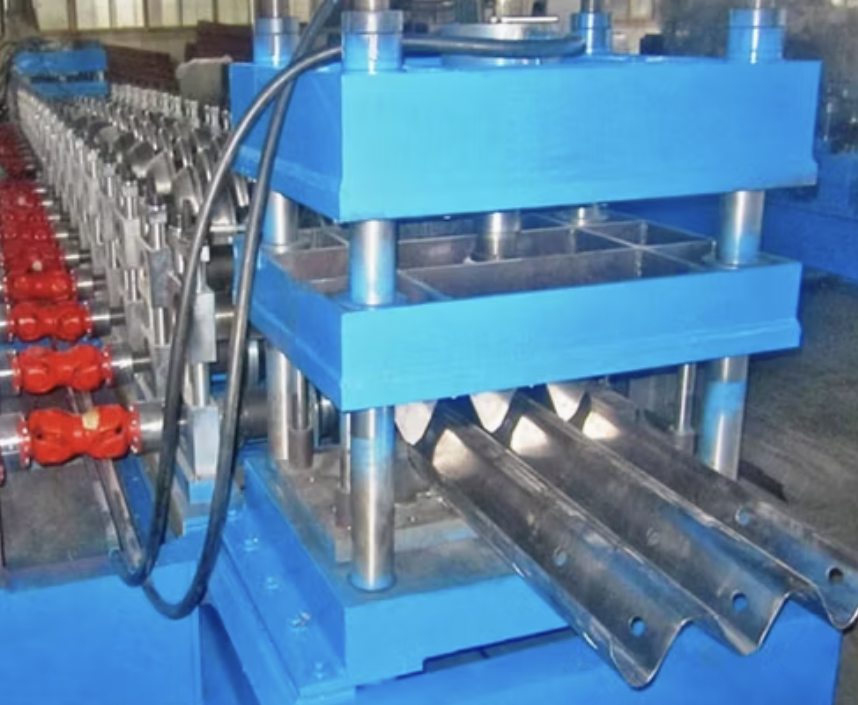

A guardrail roll forming machine processes steel coils into guardrails through a continuous bending operation. The machine typically consists of several components, including a decoiler, leveling system, roll forming stands, cutting system, and automated stacking mechanism. Advanced models also incorporate safety guards, hydraulic and pneumatic systems, and user-friendly PLC controls for optimal performance.

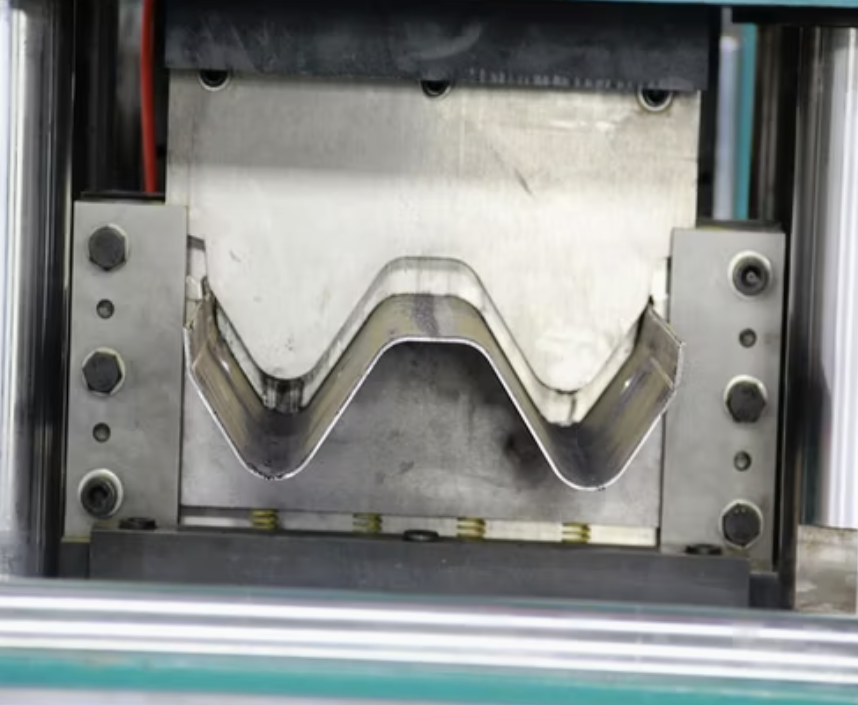

Guardrails manufactured by these machines often feature a distinctive "W-beam" profile with rounded edges, specifically engineered to absorb impact and protect vehicles and pedestrians on the road.

Regular maintenance is vital to keep the guardrail roll forming machine in optimal working condition. Key areas to focus on include:

Q1: What is the average production speed of a guardrail roll forming machine?

A: Production speed varies based on machine specifications but typically ranges between 10-15 meters per minute, with higher-end models reaching up to 20 meters per minute.

Q2: Can guardrail roll forming machines work with different materials?

A: Yes, most machines are designed to handle different grades of steel, including galvanized and stainless steel. The operator can adjust machine settings to accommodate varying material thicknesses.

Q3: What are the typical sizes of guardrails produced by these machines?

A: Guardrails generally follow standard profiles like the "W-beam" or "Thrie-beam," but width, thickness, and length can be customized according to local regulations and project requirements.

Q4: How does the punching system work?

A: The hydraulic punching unit operates in sync with the roll forming process, creating precise holes along the guardrail for mounting. Hole patterns can be customized based on project needs.

Q5: Is operator training required for using this machine?

A: Yes, operator training is recommended, especially for managing PLC systems, safety protocols, and routine maintenance tasks. Most manufacturers offer training programs for new users.

Q6: Can I add custom features or profiles to the machine?

A: Many manufacturers offer customization options for guardrail roll forming machines, including different profile shapes, punching patterns, and additional features like stackers and coil handling systems.

Q7: What power requirements are typical for a guardrail roll forming machine?

A: Power requirements depend on the machine model but generally range between 380V and 415V, three-phase. Always consult with the manufacturer to ensure compatibility with your facility's power supply.

Q8: How frequently should I perform maintenance?

A: It is recommended to conduct routine maintenance checks weekly, with more in-depth inspections on a monthly and annual basis to ensure the machine remains in optimal condition.

Copyright 2026 © Machine Matcher.