To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

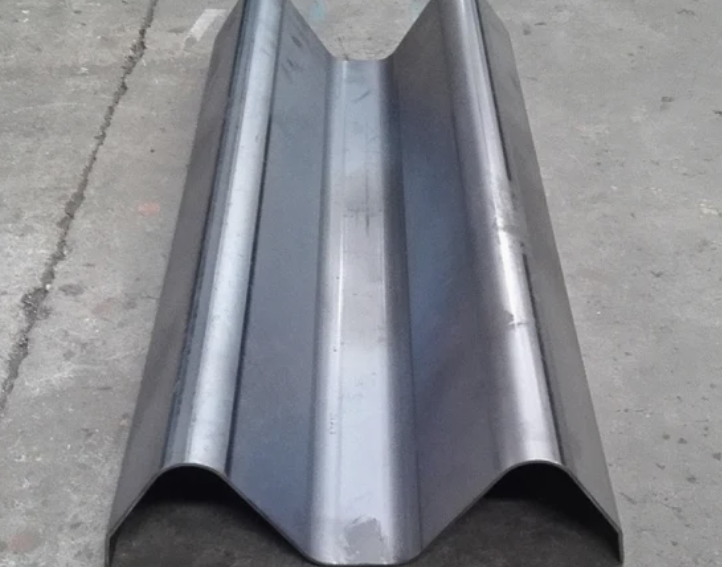

A guardrail roll forming machine is a specialized type of roll forming equipment designed to produce guardrail profiles for roads and highways. These machines are designed to meet high production demands and can produce guardrails in various profiles, typically the W-beam and Thrie-beam. Here's a breakdown of typical specifications and descriptions for these machines:

A guardrail roll forming machine is a robust and efficient production solution for guardrail manufacturers. It enables the continuous shaping of metal sheets into guardrail profiles with precise dimensions and uniform quality. The machine includes a decoiler for feeding metal sheets, followed by a roll forming section where rollers progressively bend the sheet into the desired profile.

Advanced PLC controls allow for easy operation and accurate adjustments in the production line, ensuring a high degree of precision. The hydraulic cutting system cuts the formed guardrails to specified lengths, while some models feature a punching system for bolt holes, typically in accordance with international standards.

These machines are ideal for manufacturers seeking consistent, high-quality guardrail production and are often designed to produce both W-beam and Thrie-beam profiles by adjusting or replacing roller sets.

Copyright 2026 © Machine Matcher.