To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

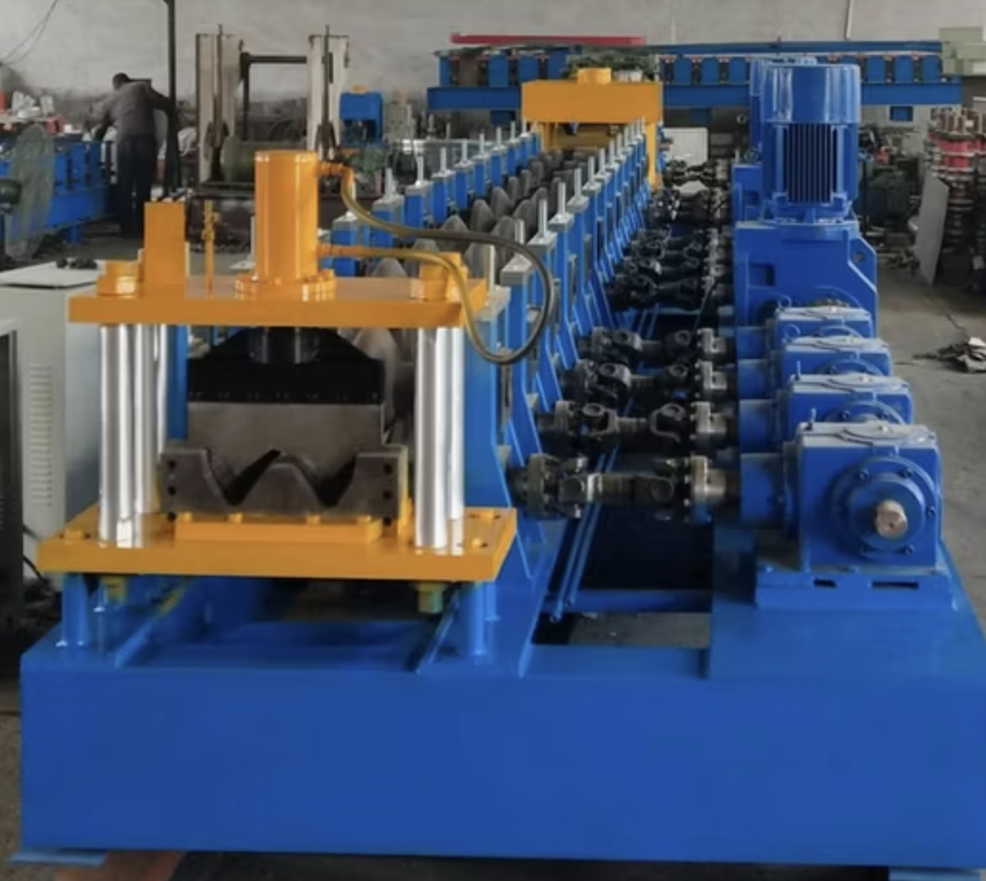

Guardrail roll forming machines are essential equipment for manufacturing safety barriers, specifically highway guardrails. These machines are designed to produce guardrails that meet strict international safety standards, ensuring road safety and minimizing accidents. Their application spans highways, bridges, and parking lots, making them vital for Portugal's expanding infrastructure.

A guardrail roll forming machine automates the production of steel guardrails through a cold roll forming process. The machine takes flat steel sheets or coils and transforms them into W-beam or other customized guardrail profiles.

This equipment is renowned for its efficiency, precision, and ability to produce consistent, high-quality profiles suitable for Portuguese road safety standards.

The pricing for a guardrail roll forming machine in Portugal varies based on customization and additional features:

Q1: What types of guardrail profiles can this machine produce?

A: The machine can produce standard W-beam (two-wave) and Thrie-beam (three-wave) profiles. Customization is also possible based on specific road safety standards in Portugal.

Q2: What materials can the machine process?

A: It supports galvanized steel, stainless steel, and aluminum with thicknesses ranging from 2 mm to 4 mm.

Q3: How long does installation take?

A: The installation process typically takes 5-7 days with professional technician support.

Q4: Does the machine comply with EU safety standards?

A: Yes, the machine is CE-certified and complies with all EU safety and quality regulations.

Q5: Can the machine handle custom punching and notching?

A: Yes, the punching and notching unit is highly customizable for various hole patterns and designs.

Q6: What is the warranty period?

A: The machine comes with a 1-year warranty, covering major components like motors and PLC systems.

Q7: Is it possible to get spare parts in Portugal?

A: Yes, spare parts can be sourced locally or directly from the manufacturer.

By investing in a guardrail roll forming machine, Portuguese businesses can enhance their manufacturing capabilities, support infrastructure projects, and contribute to road safety.

Copyright 2026 © Machine Matcher.