To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

A gutter roll forming machine is a specialized piece of equipment designed to manufacture seamless gutters from sheet metal. These machines are widely used in construction projects to create drainage solutions for residential, commercial, and industrial buildings. In Algeria, where diverse climatic conditions require efficient water management systems, gutter roll forming machines are essential for producing high-quality, durable gutters tailored to local requirements.

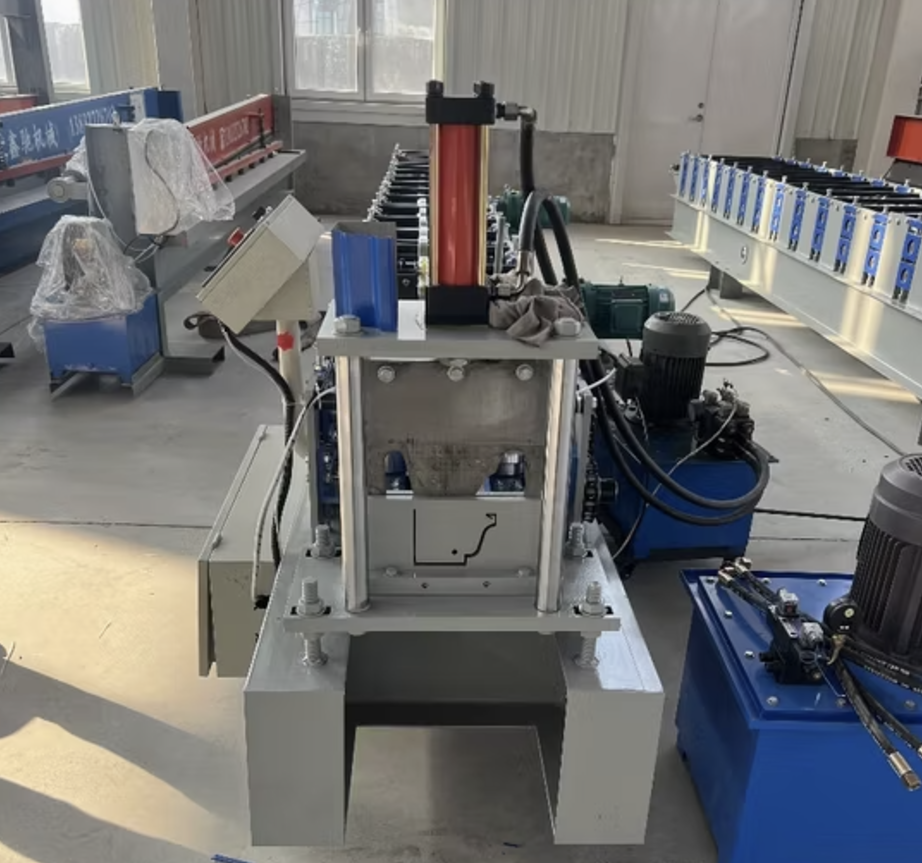

The gutter roll forming machine transforms metal coils into continuous gutter profiles with precise dimensions and smooth finishes. It operates efficiently, allowing for mass production of gutters while minimizing material wastage. The machine can produce various gutter profiles, including K-style, half-round, box gutters, and more, depending on the tooling setup.

Key Features:

Below are the typical specifications of a gutter roll forming machine. Customizations may be available based on project needs in Algeria:

| Parameter | Specification |

|---|---|

| Material Thickness | 0.3 mm - 0.8 mm |

| Material Types | Galvanized steel, aluminum, copper, pre-painted steel |

| Profile Types | K-style, half-round, box profiles |

| Machine Speed | 10-20 meters per minute |

| Roller Material | High-grade steel with hard chrome plating |

| Frame Structure | Welded steel structure for stability |

| Drive System | Hydraulic or servo motor-driven system |

| Cutting System | Hydraulic cutting with high precision |

| Control System | PLC with touchscreen interface |

| Power Supply | 380V, 50Hz (customizable to local Algerian power standards) |

| Dimensions | Length: 8-12 meters, Width: 1.5-2 meters |

| Weight | Approximately 6-8 tons |

| Optional Extras | Decoilers, stacking systems, remote monitoring PLC |

The Algerian market has a growing demand for roll forming machines, especially for infrastructure and construction projects. Gutter roll forming machines are vital for:

Q1. What materials are compatible with the gutter roll forming machine in Algeria?

A1. The machine can process galvanized steel, pre-painted steel, aluminum, and copper, commonly available in Algeria.

Q2. Can the machine produce multiple gutter profiles?

A2. Yes, it is equipped with adjustable tooling to create various profiles like K-style, half-round, and box gutters.

Q3. How is the machine powered, and is it compatible with Algerian electricity standards?

A3. The standard power requirement is 380V, 50Hz, but it can be customized to suit local Algerian power conditions.

Q4. What optional features are available?

A4. Optional features include automatic decoilers, stackers, and remote monitoring systems for added efficiency and convenience.

Q5. How long does it take to install and set up the machine?

A5. Installation typically takes 2-3 days, depending on the complexity of the setup and the availability of skilled technicians.

Q6. Is training provided for operators?

A6. Yes, most suppliers include training sessions for operators to ensure efficient and safe machine use.

Q7. How do I maintain the machine to ensure longevity?

A7. Regular lubrication, cleaning of rollers, and periodic checks of the hydraulic and PLC systems are essential for optimal performance.

Q8. What is the cost range for a gutter roll forming machine in Algeria?

A8. The cost varies based on specifications, optional features, and supplier pricing, typically ranging from $30,000 to $80,000.

Copyright 2026 © Machine Matcher.